#Recycling / Circular Economy

Advancing circular solutions with chemistry

- Innovative development for chemical recycling processes

- New product applications designed for recycling

- Circular product concept launches with Desmodur®CQ

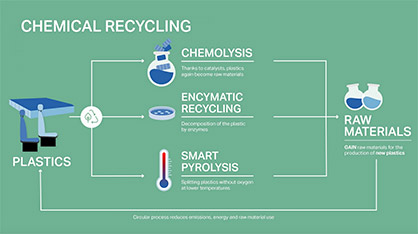

Covestro intends to focus entirely on the Circular Economy. The company is driving the development of innovative and resource-saving processes to make its products recyclable to meet this goal. That is why Covestro intends to offer more material solutions based on sustainability and circularity in the markets in which it is active. Covestro's own technological development is focused on four recycling approaches. In addition to mechanical recycling, which is already used for the high-performance plastic polycarbonate and thermoplastic polyurethane (TPU), Covestro is developing chemical recycling processes: These include chemolysis, smart pyrolysis and enzymatic recycling. The aim of these processes is to produce recycled plastics in virgin material quality while significantly reducing the environmental footprint compared to the conventional fossil-based production of polymers and polymer raw materials. Covestro applies its core competence in chemistry to process development.

"We see ourselves as the driving force behind the Circular Economy industry that is currently being developed, where the chemical and waste management industries will have to grow closer together in perspective and synergies will have to be created," explains Markus Steilemann, Chairman of the Board of Covestro. "We are moving forward here with vigor for the entire industry: with various recycling approaches, we can systematically recover the different raw materials we need for the production of our plastics. Our goal is to fully circularize materials from end-of-life products to save fossil raw materials and greenhouse gas emissions, while offering recycled high-performance materials in virgin quality." The company plans to invest around one billion Euro in Circular Economy projects by 2030. In Leverkusen, Covestro already operates a pilot plant for the chemical recycling of flexible polyurethane foams.

In addition, Covestro will showcase how circular solutions in the product portfolio can be made even more visible to customers at IFAT in Munich. With the "CQ" concept, in the future Covestro will highlight the alternative raw material base in products if it is at least 25 percent. "CQ" here stands for Circular Intelligence. Among the first "CQ" products is Desmodur®CQ. Polyurethanes based on Desmodur®CQ are deployed, for example, in upholstered furniture, mattresses and thermal insulation. They are used, for example, as coatings for cars or household appliances.

"In order to take meaningful climate protection measures, we need a change, a paradigm shift, for us, our customers and everyone else in the entire value chain. At the same time, the benefits must be clear in the application of such solutions. The chemical industry must fundamentally change as a central part of the value chain - toward alternative raw materials and renewable energies," says Sucheta Govil, Chief Commercial Officer at Covestro. "We have set ambitious targets to make our production fully circular and ultimately independent of fossil resources. In doing so, we are supporting a wide range of industries to reduce the carbon footprint of their own products," Govil said.

Cooperations provide contribution to full Circular Economy

New recycling processes and cooperation with partners from industry and research are making an important contribution to achieving full circularity. For example, Covestro is coordinating the EU project "CIRCULAR FOAM" with 22 partners from nine countries. The aim of the project is to develop innovative chemical recycling processes for rigid polyurethane foams. As an insulating material, rigid polyurethane foams contribute to the energy efficiency of refrigerators and buildings - but coordinated waste management and suitable recycling processes are still lacking for a sustainable life cycle. Chemical recycling could save up to one million tons of waste and 2.9 million tons of CO2 annually from 2040.

Markus Steilemann and Sucheta Govil at IFAT

To kick off IFAT on Monday, May 30, 2022, Sucheta Govil will be a guest on the show's opening session. The topic will be the role of environmental technologies for a more sustainable future. Participants will include founder Mikela Druckman, an expert on AI in recycling and a member of the WEF Global Future Council; Prof. Dr. Erich Zahn, co-author of the Club of Rome report "The Limits to Growth"; Dr. Johannes Kirchhoff, Board of Management of the Circular Economy Initiative from the Federation of German Industries; and Ren Xiaoyuan, (UNEP) Young Champions of the Earth 2020 and founder of the water information network MyH2O.

CEO Markus Steilemann will discuss the topic "Global Value Creation in the Crisis? The Circular Economy as Europe's Response" on a BDI panel on Tuesday, May 31, at 2:15 p.m. with Delara Burkhardt, environmental policy spokeswoman for the Socialists and Democrats delegation in the European Parliament, Dr. Christoph Epping, head of the Circular Economy subdivision at the German Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection, and Wolfgang Niedermark, member of the BDI's Board of Management. On Wednesday, June 1, Markus Steilemann will give an introduction at 12:15 p.m. to the panel discussion "Chemistry for circular mobility: Chemical recycling as a building block of circular value creation for automotive?" with experts from Audi, Covestro and TU Dortmund University.

Covestro at IFAT 2022 in Munich, Germany

• DGAW booth (Hall/Booth: A6 125/224) and VCI booth (Hall/Booth: A6 231)

• Monday, 30 May, 11:50 a.m. - 1 p.m.: Opening panel "How to create change?" - From activism and politics to environmental solutions and impacts" with Sucheta Govil (Forum Water Hall C3. 139/238)

• Tuesday, May 31, 2:15 p.m., (Hall C6, Room C62a, BDI Initiative Circular Economy), and Wednesday, June 1, 2022 (12:15 p.m., Hall A5 | 317/416 | Waste / Secondary Materials Forum): Markus Steilemann visits IFAT