#Recycling / Circular Economy

rPET pellets for BOPET film production

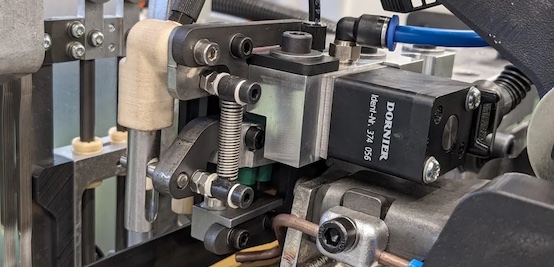

EREMA and DORNIER combine machine components to create an innovative recycling solution

They combined an INTAREMA 1512 TE recycling machine with a DORNIER melt filter for fine filtration. The compact INTAREMA® recycling system has proven its merits again and again over the years for the recycling of BOPET and BOPP waste in the manufacture of packaging film. The EREMA machine features a short single screw extruder and in the TE series is equipped with double degassing. The Lindauer DORNIER melt filter is an electric-heated filter that the manufacturer of weaving machines and specialty machines normally implements in the extrusion stage of its film stretching lines. The filter is designed individually for the required throughput of the customer and is suitable for 10 µm filtration grade.

Even when operated around the clock, a filter change is only necessary every four weeks. The integration of these two components reduces the load on the melt filters in the film stretching system during further processing of the recycled pellets, because the fine filtration of the rPET material has already been carried out during the recycling process. As a result, it increases the availability and production output of the film stretching line.

The customer that operates this recycling combination uses it to process washed PET bottle flakes that they buy-in. The flakes have a bulk density of 370 kg/m³ and measure between 0.6 and 8 mm. The 3 x 3 x 2 mm recycled pellets with a bulk density of 700 to 800 kg/m³ are part of the recipe for a biaxially stretched polyester film with a thickness of 23 and 30 µm for industrial applications. The main extrusion layer of this BOPET film is manufactured using a recycled pellet content of 30 percent. Additional clouding of the film cannot be detected as a result.

By investing in this recycling machine, the customer is now able to continuously monitor the processing of the bought-in PET bottle flakes themselves. This means that they have full control over the quality of the recycled pellets as well as in-house added value. "Our customers' customers increasingly specify plastic film with the highest possible proportion of recycled polyester. With the recycling machine especially configured by EREMA and DORNIER for this application, the recycled pellets are optimised to match the highest possible performance of the film stretching line," says Michael Stötzel, Head of Service at DORNIER. "Overall, the demand for higher proportions of rPET in film products is continuing to grow," confirms Andreas Dirnberger, Business Development Manager Application Inhouse & Industrial in the EREMA Group: "Film manufacturers are driven by the development of sustainable product concepts. The high quality rPET pellets that this customer now produces is the result of the ongoing technological development of the post-consumer material recycling process. This is only possible if the project partners work together efficiently towards the same goal." EREMA and DORNIER have been cooperating for many years on in-house recycling solutions for BOPET film manufacturers. "The fact that the teams involved in this project are already familiar with each other's product was certainly a decisive success factor for this customer's application," say Michael Stötzel and Andreas Dirnberger in agreement.