#Recycling / Circular Economy

Circ® and Selenis enter strategic partnership to scale textile-to-textile polyester production in Europe

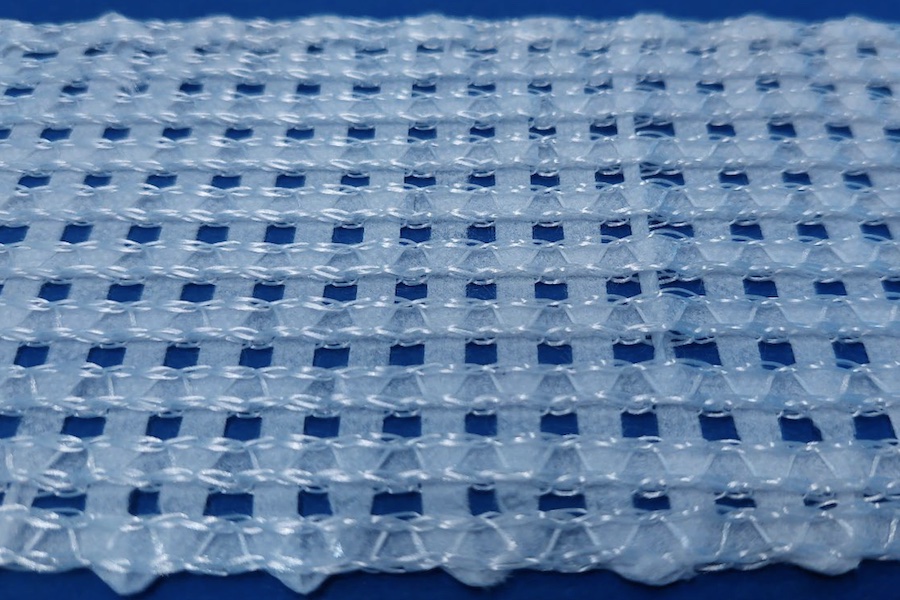

This industrial collaboration allows Circ® to leverage Selenis’ proven polymerization infrastructure and technical expertise to transform recycled monomers from end-of-life textiles into high-quality Circ® Polyester, ready for application across apparel categories including activewear, basics and fashion. The result is a scalable, circular solution that integrates seamlessly into existing supply chains.

“Selenis has been a long-standing partner in our journey, and we’re proud to take this next step with them to bring Circ® Polyester to market at industrial volumes. This is also a defining moment that affirms Circ’s dual-product strategy, offering both recycled lyocell and polyester—as we meet growing demand for circular materials across categories,” said Peter Majeranowski, CEO of Circ®.

A trusted producer of high-performance polyesters for various end markets, Selenis brings decades of technical expertise and operational excellence to the partnership. Their collaboration with Circ® is advancing the next generation of recycled polyester and expanding the range of circular solutions available to fiber producers, mills, and fashion brands alike.

“This partnership reflects our commitment to reducing waste and scaling up advanced recycling solutions," said Duarte Matos Gil, CEO of Selenis. “Circularity is no longer a concept; it must become an industrial reality. Whether it is bottle-to-bottle or textile-to-textile, the goal is the same: materials must complete a full life cycle and return as high-quality products, again and again. A bottle should become a new bottle, not downcycled. A garment should be reborn as another garment, not wasted. To achieve this on a scale, we need both innovation and regulation. Supportive, forward-looking legislation is essential to unlock investment and create a level playing field for truly circular systems.”

“While the world was focused on recycling for packaging, our strategy since 2022 was to lead textile circularity,” added Eduardo Santos, Global Head of Corporate Strategy at Selenis. “We committed our resources and innovation to explore the textile side of the problem, even when our core business was in plastics. This partnership with Circ®, officially launched in June 2023, represents a tangible step in tackling fast fashion’s impact on the environment. We’ve made strategic advances – first in the U.S. and now, in Italy – strengthening our position in textile circularity across both sides of the Atlantic.”