#Research & Development

Soft interfaces: Textile-integrated light switches, made possible by printable Liquid Metal Ink

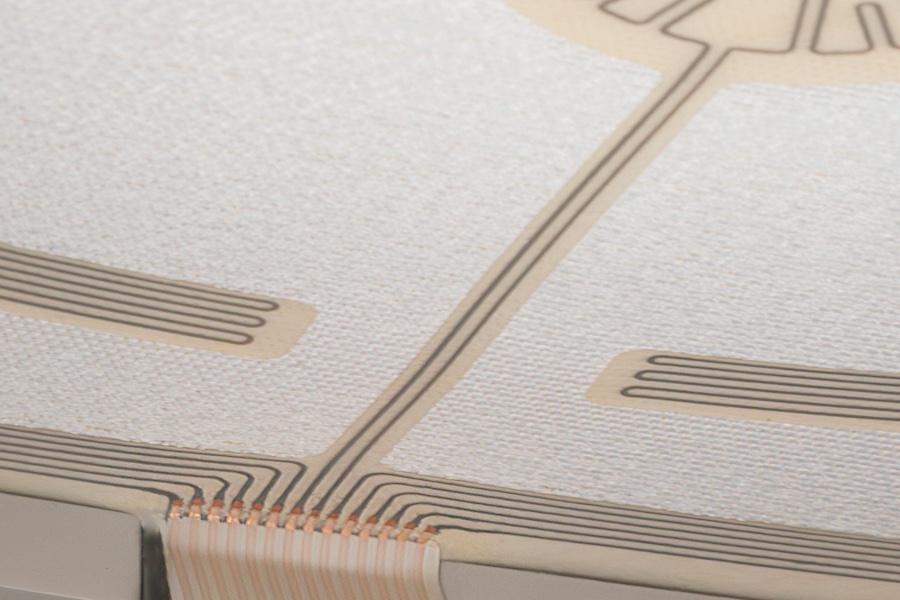

Lukas Werft and Christian Dils of the Fraunhofer Institute for Reliability and Microintegration IZM and their counterparts, Robin Hoske and Felix Rasehorn of WINT Design Lab, are coming to the Berlin Science Week to reveal their »Soft Interfaces« project to the waiting public. The aim of this innovative research is to develop textiles that can respond to touch and interact intelligently with their environment. The project’s magic lies in the newly developed and fully printable Liquid Metal Ink (LMI) made with Galinstan. The electrically conductive ink is covered in highly elastic thermoplastic polyurethane (TPU) and can be laminated right into knitted textiles to create surfaces that are not just functionally usable, but also flexible, stretchable, pleasing to touch and pleasing to the eye.

Showcasing the technology with a special lamp

One great example that shows the capabilities of the technology is an interactive, 3D-printed lamp with a special textile lampshade. The clean lines of the 3D-printed lamp are not harmed by any intrusive switches or buttons. Only a subtle difference in the knitted pattern invites users to touch the flat lampshade, intuitively switching the light on or off. LEDs are integrated into the body of the lamp that can be dimmed or change their color in this way.

The lampshade is made from a knitted fabric stretched over a 3D-printed frame. It includes seven LMI sensor units for controlling the light intuitively. With a simple touch, the user can turn the light on or off, dim the light, or change the color temperature. The fabric itself becomes the user interface, opening up a whole new dimension of interactivity.

Innovative technology

All of this is made possible by the newly invented Liquid Metal Ink (LMI), an electrically conductive, but also environmentally friendly ink that works with Galinstan. This alloy of gallium, indium, and tin is mixed with a solution of thermoplastic polyurethane (TPU), resulting in the viscous LMI that can be printed onto elastic substrates to create structures that work like resistive strain sensors. Gentle pressure is enough, and the resistivity of the material changes, alerting the light controllers to switch on the lamp, dim the light, or change its color.

Interdisciplinary collaboration

The project was born from the close cooperation between design and material science that is supported by the Fraunhofer Network »Science, Art, Design. « Regular workshopsand collaborative work at Fraunhofer IZM and WINT Design Lab brought together technological know-how and product and interaction design insights into a streamlined tactile user experience.

Future opportunities

»Soft Interfaces« shows the great potential of liquid metal conductors for diverse applications in elastic fabrics, from novel control interfaces for smart home textiles, intuitively functional surfaces for vehicles, or wearable sensors to soft robotics. The technology is currently still limited to laboratory or prototype uses, but is very promising for scalable, energy-efficient products.

On November 1st and 2nd, 2025 researchers from the Fraunhofer network »Science, Art, Design« will be on site at the Museum of Natural History’s CAMPUS as part of the Berlin Science Week. For more information, visit: https://berlinscienceweek.com/programme/textilien-die-fuhlen-mit-intelligenten-oberflachen-zur-neuartigen-interaktion

Credits:

Technical Management: Fraunhofer IZM (Lukas Werft, Christian Dils, Carlos Wisbar, Raphael Mgeladse)

Design: WINT Design Lab (Felix Rasehorn, Robin Hoske, Julia Huhnholz)

Fabric Development: Case Studies (Laura Krauthausen, Konstantin Laschkow)

Video und Fotografie: Michelle Mantel

Project Funding: Fraunhofer Network »Science, Art, Design (WKD)«