#INDEX 23

INDEX™ : Sustainable nonwovens developments for Geneva

Bio-based hygiene nonwoven: BioHyg

The starting point for the innovation was the search for a washable and thus reusable absorbent pad made from completely bio-based materials for applications in baby, feminine and incontinence hygiene. The focus was on two main requirements: fast and efficient liquid distribution and high absorbency to minimize rewetting and leakage. Both are guaranteed by special viscose fibers from Kelheim Fibres, which have been making this essential contribution in absorbent hygiene products such as tampons for many years.

Here, the advantages of nonwovens in combination with special viscose fibers in terms of absorptive capacity (through, for example, more open-pored structures) have been perfectly transferred from the petrochemical- to the world of biobased fiber materials. For reusable products, however, there is another challenge to overcome: they must remain stable during washing and over several cycles of use. To ensure this, an innovative nonwoven construction was developed at the Saxon Textile Research Institute (Sächsisches Textilforschungsinstitut e.V.). The developed nonwovens close the technological gap between sufficient dimensional stability and as little fiber damage as possible due to the bonding mechanisms. The developed nonwoven layers can be used as a stand-alone solution as a single-use product with bio-based materials or integrated into a washable composite structure, such as the diaper from start-up Sumo. In the Sumo cloth diaper, the absorbent pad's fluid management sets new standards. The new solution combines the worlds of hygiene and sustainability and provides proof that high-performance reusable absorbent products can be developed without fossil materials.

The research collaboration between STFI, Kelheim Fibres GmbH and Sumo GmbH received the 2022 Techtextil Innovation Award in the "New Concept" category for the development of a bio-based hygiene nonwoven - a good example of how research and industry are breaking new ground in sustainability through collaboration in an open innovation approach.

Recycling of high performance fibers: VliesSMC

STFI will be showing innovations in the recycling of high-performance fibers at INDEX™ 23. On display will be a battery housing developed jointly with the research partner Fraunhofer ICT, Pfinztal. Detailed investigations into the use of recycled carbon fibers in the SMC process chain were carried out at STFI, Chemnitz. To this end, nonwovens were first developed that enable the recycled carbon fibers to be fed into the SMC plant.

The SMC semi-finished products produced could then be processed by both molding and impact extrusion.

Comparison with conventional SMC products showed that comparable characteristic values could be achieved with a lower fiber volume content. Developments in the field of renewable raw materials in combination with bio-based resin systems also offer forward-looking materials.Further project information: VliesSMC

Innovative hose liner system

The aim of the research project was to develop an improved pipe liner system for trenchless pipe rehabilitation.

In particular, the force absorption in the longitudinal direction, the bendability without wrinkling were improved and the use of material as well as the pore volume of the textiles were optimized for the best possible impregnation with resin. The project included nonwoven development, coating of the liners and the use of UV-curable resins for curing. At INDEX™ 23, STFI will present a demonstrator showing a nonwoven-based pipe liner with coating, which in turn was impregnated with a UV-curable resin and cured using UV LED lamps. (49MF200100)

From recycled fibers to water-jet nonwovens

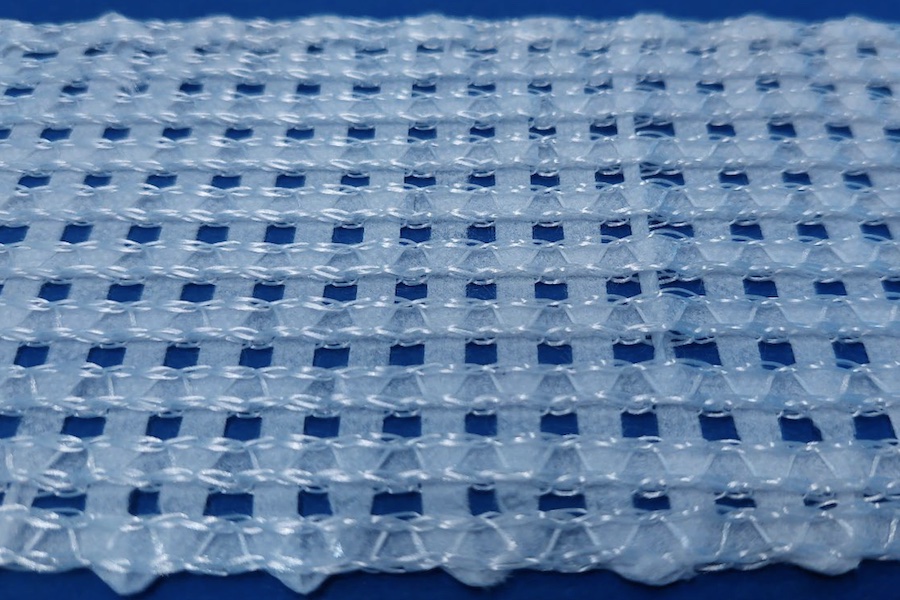

At INDEXTM 23, STFI will be exhibiting nonwoven structures that have been bonded by the waterjet process or stitch-bonding technologies after mechanical recycling by means of a tearing machine. The nonwovens are characterized by their soft feel and unique appearance. Whether wet-strength wipes, classic knitted pile fiber nonwovens with cushioning and insulating properties or sustainable needle-punched nonwovens; by using torn fibers in combination with established nonwoven formation processes, new applications for used textiles are found at STFI and material cycles are closed.

We would like to discuss with you the possibility of joint research projects and suitable funding programs. Have we aroused your interest? We are looking forward to exciting discussions with you. Visit us at the INDEX™23 at booth 1369.