#Nonwovens / Technical Textiles

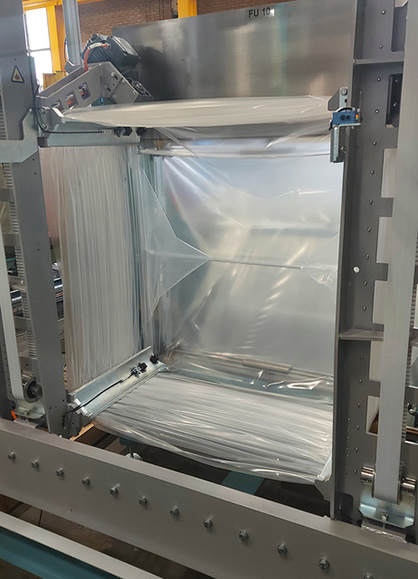

New XL Power packaging machine from Tentoma: Enables up to 19 m long packaging of nonwoven rolls

Designed for stretching even more film

The XL Power packaging machine has more forces for stretching film. It means that XL Power can load and stretch even more film on the gripper arms during the packaging process. It opens opportunities for more packaging improvements. Most obvious is the increased maximum length of the products, which now can be packed and protected by a 100% waterproof packaging. Depending on product shape and film thickness, it is now possible to pack and seal products up to 19 meters long. It is an increase in product length of 50%1), compared to the standard RoRo StretchPack® XL machine.

Increases packaging speed by up to 25%

Another benefit from XL Power is increased packaging speed. The ability to load and stretch even more film on the gripper arms increases the packaging speed when using the “Semiflow packaging” principle. “Semiflow packaging” enables the packaging of multiple products in a row before the machine needs to load more film on the gripper arms. XL Power can load and stretch even more film on the gripper arms, so it is possible to pack even more products in a row compared to the XL machine. A comparison between XL and XL Power shows that when the XL machine packs 210 products per hour, the new XL Power machine packs 260 products. It means an increase in the packaging speed of est. 25%2) when using XL Power.

Technical speaking, the new XL Power is a reinforced version of the proven RoRo StretchPack® XL packaging machine. The main improvements on the XL Power machine are: 1) It is equipped with stronger and longer gripper arms to load more film. 2) The motors have become more powerful to stretch even more film. 3) The steel construction has become stronger to withstand the increased tensile forces. As all the RoRo StretchPack® machines, XL Power will be adapted to the production line and the specific packaging requirement.