#INDEX 20

Right fiber, right fabric – automatically

Uster offers a combined solution for nonwovens quality control

EDANA and INDA, the leading global nonwovens associations, recently issued the 2021 edition of their ‘Standard Procedures’ guidance for nonwovens and related industries. These authoritative documents aim to define, in technical terms, relevant products – including 107 individual test regimes. This special article covers a range of intermediate measures and test processes for spunlace and other nonwoven technologies – leading ultimately to products with top class designations.

Pure fibers only

Nonwoven materials can’t really be better than the fibers they are made of. But there is a real threat to the quality of nonwovens caused by contamination. Fiber cleaning is the solution and bundle size is the key detail: small contaminant particles can hide inside bigger bundles, making them especially difficult to locate when the material is more compressed. Uster Jossi Vision Shield N is ideally positioned in the line to overcome this, directly behind the fine opener. This ensures that the fiber bundles pass the spectroscopes in their most open state.

Uster Jossi Vision Shield N is the result of surveys, close collaboration with international nonwovens companies and countless hours of field tests. Installation is easy, since the fiber cleaner’s slim design fits perfectly into existing lines – and readily copes with the high output of standard production lines. For best detection results, the fiber cleaner is tuned to identify the typical contamination types in nonwovens, including colored fibers.

Growing demand, growing needs

In Europe last year, medical applications recorded an increase in demand of 118% and wipes personal care plus 22%. These are the top two growing segments according to EDANA – and they are also the ones showing a trend towards zero tolerance levels for defects larger than 1 mm. While other technologies use conventional color cameras, the built-in spectroscopes of Uster Jossi Vision Shield N operate on a much greater wavelength range. This enables detection of contamination within the ‘invisible’ range of infrared and ultraviolet light, and even contamination fragments of the same or similar shade as the fibers themselves – down to the fineness of a human hair.

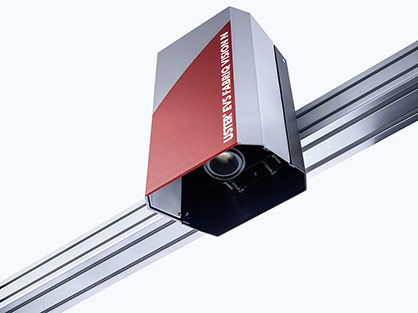

For the record: Uster Jossi Vision Shield N is made in Uster, Switzerland. So is Uster EVS Fabriq Vision N, the nonwovens quality assurance system which ensures a consistently high rate of fault detection using automated inspection during the production process. “Our customers aim for confidence in delivering the right quality to strengthen their own customer relationships. With Uster EVS Fabriq Vision N, they can guarantee quality compliance and protect their business,” says Grégory Winiger, Area Sales Manager at Uster Technologies.

The right quality on the roll

The Uster nonwovens systems lead to total fabric quality assurance by using automated control during intermediate inspection. Uster EVS Fabriq Vision N locates any visible faults objectively and consistently. Defects in every roll are located and recorded in a defect map, at full line running speeds.

Uster EVS Fabriq Vision N enables seamless integration of an inspection system into any production process – and ideally into nonwovens manufacturing lines – detecting contamination, holes, irregularities and any other defect. Installation is simple and flexible: a fixture bar bridges the full width of the process line, holding as many spectroscopes as required for the application.

“With improved quality, as well as improved first-quality efficiency, Uster EVS Fabriq Vision N offers an additional advantage for all applications,” says Winiger. The combination of a full map of fabric defects and the cut optimization module means more first-quality rolls can be produced and bad quality taken out.

Complete quality solution

The combination of Uster automated contamination removal and quality assurance is the best solution today for nonwovens producers to protect quality, avoid material waste and take full advantage of the potential for process optimization. “The combination of Uster Jossi Vision Shield N and Uster EVS Fabriq Vision N means that Uster can offer a complete and unique quality monitoring solution for the nonwoven industry,” says Winiger.

Uster will present this solution at INDEX 2020, in Geneva, Switzerland from October, 19th to 22nd 2021. Uster experts are ready to welcome visitors, pass on information and answer visitors’ questions at Booth 1402 in Hall 1.