#Nonwovens / Technical Textiles

Trützschler Nonwovens technology in China: During the pandemic and beyond

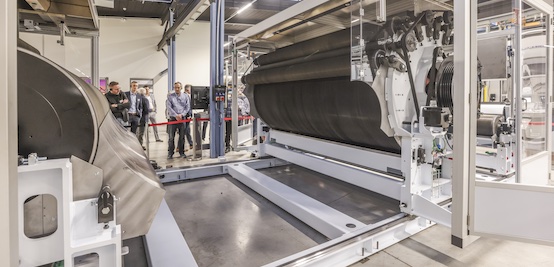

Soon after the outbreak of COVID-19, many Chinese nonwoven producers recognized a big opportunity for business growth. There was a strong demand for spunlaced wet and dry wipes like disinfectant wipes. These wipes are mostly hydroentangled and ideally consist of blended polyester and viscose fibers: Whereas the polyester fiber does not adsorb the disinfectant and secures antimicrobial efficacy, the viscose fiber is able to soak the liquid. This combination leads to perfect strength, volume and softness at the same time while the spunlace process makes the wipes lintfree. Trützschler Nonwovens in China demonstrated the flexibility and expertise needed to immediately focus on this need.

After the boom

The demand for spunlaced equipment flattened at the beginning of 2021 and the market normalized back to the very good growth that it has seen in the past. In general, the huge popularity of the technology mainly comes from rising household incomes. The majority of spunlaced nonwovens is used for single-use convenience products like baby, body and household wipes, as well as cotton pads, beauty masks and femcare products. Reliable and efficient spunlacing equipment is also encouraging producers to explore durable end uses such as coating substrates for artificial leather or hot gas filtration media. Accordingly, investments in spunlaced nonwovens are still important and customers like Sateri, Kingsafe, Zhongtai, and Wangjin, who belong to the main producers in China, are confident that spunlaced nonwovens will continue to be a key driver in the double-digit growth of nonwovens in China. Trützschler is the partner of choice to be equipped for the expected long-term growth in this area.

“We bought two spunlacing lines from Trützschler in 2020, which means we’ve now installed five of their spunlacing lines since 2015,” says Mr. Yan Huarong, Chairman of Zhejiang Kingsafe Group Co., Ltd, one of the 10 biggest producers of nonwovens in China and the largest producer of spunlaced (hydroentangled) nonwovens in Asia. “I’m impressed by the high productivity and speed of our Trützschler machines.”

Trützschler as first choice for every market situation

Why have customers been choosing Trützschler as a partner before, during and after the pandemic situation in China? The answer is: Trützschler has the agility to support them under any market condition. True technologies and true innovations lead to higher efficiency, a better product quality and lower maintenance requirements.

Trützschler Nonwovens attaches great importance to sustainable customer relations as well as the long-term development of the entire industry. In China, we observe interesting developments in the field of spunlacing but also thermobonding and needling. We will continue to monitor this closely in order to offer our customers the best and most sustainable solutions for every market situation.