#Nonwovens / Technical Textiles

T-SUPREMA: Live Demonstration of versatility

At this year’s Techtextil event in Frankfurt, Germany, Trützschler Nonwovens presented its T-SUPREMA production concept for manufacturing different types of nonwovens on a single line – with high levels of quality, productivity and cost-efficiency. Those insights generated a huge amount of interest. And representatives from several companies got invited to see an up-and-running installation at the Technology Center in nearby Egelsbach.

The T-SUPREMA is an exciting innovation for this market because it offers unique levels of flexibility. It can produce lightweight and heavyweight nonwovens, from 30 grams per square meter (gsm) up to more than 2,000 gsm, on one production line. It also features a clean concept that minimizes downtime for cleaning or maintenance. And it is especially well-suited for producing lightweight needle-punched nonwovens, which enables cost-efficient products from this challenging application.

With the T-SUPREMA, Trützschler Nonwovens offers its customers great flexibility. They can react quickly to changes in demand or develop new products that are outside of what has been produced before. As part of the longstanding commitment to co-innovation, Trützschler joined together with Texnology to develop the T-SUPREMA. This Italian machinery manufacturer has deep specialization in mechanical needling. Its state-of-the-art needleloom designs play a key role in enabling the T-SUPREMA to serve such an extensive range of nonwoven applications.

Excitement in Egelsbach

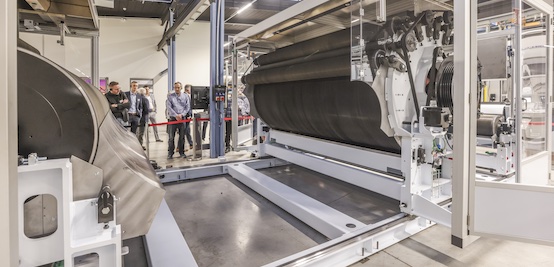

Visitors to the Trützschler Nonwovens Customer and Technology Center in Egelsbach got the chance to experience the super-flexible T-SUPREMA line in action. The industrial-scale setup has a working width of 4 meters. It also features three bale openers, a blending bin, a fine-opener, a card with 3-meter width and crosslapper, two needlelooms, a felt drafter and a winding section.

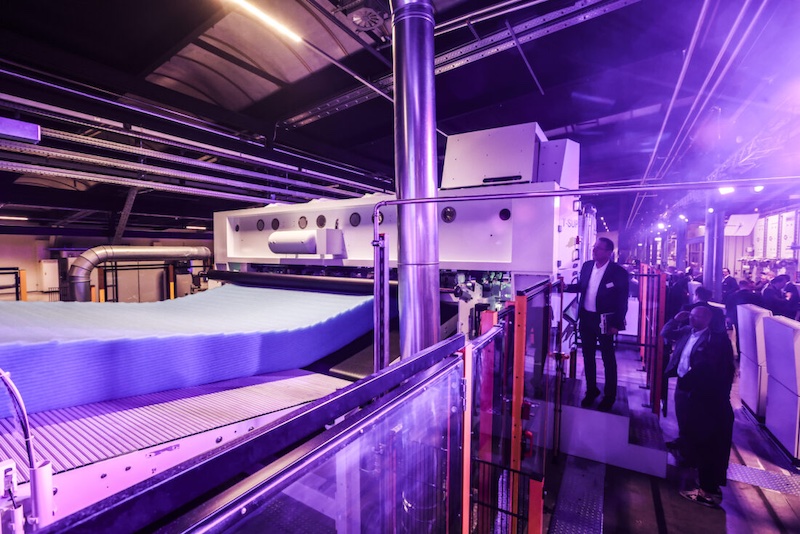

What is so special about the T-SUPREMA? Unlike other needle-punching installations, the T-SUPREMA is not optimized for one end product only: with a changeover time of about 60 minutes, customers were able to see how the same line first produced an extremely light 35 gsm nonwoven with three double layers after the crosslapper, in which a microfiber was used. Later, after the short changeover time, the line produced a 1,400 gsm nonwoven with 23 double layers after the crosslapper, using the typical coarse fibers with 3.3 and 6.7 dtex. This production process was underlined by an impressive light show.

Test the T-SUPREMA

Tests and trials with this high-performance needle-punching line have already impressed companies from across the global nonwovens industry. The production speed, ease of use and broad working window have captured hearts and minds. And the overall output quality of the uniquely broad range of products has also grabbed the attention of visitors to Egelsbach – with more trials planned: More and more companies are booking tests at the Technology Center. From lightweight to heavyweight nonwovens, the T-SUPREMA can produce them all.

Interested parties are welcome to convince themselves of the performance in person and arrange a booking for a trial.