#Nonwovens / Technical Textiles

Truetzschler solutions for sustainable nonwovens

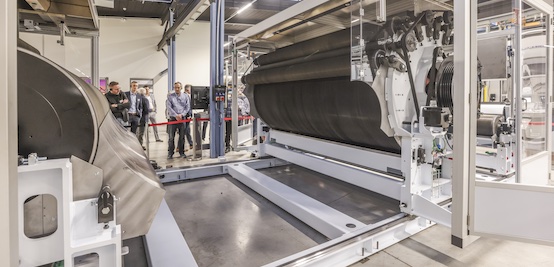

Against the backround of a rising demand for single-use nonwoven products which lead to a growing volume of waste and legislative efforts to reduce single-use plastics, e.g. in China and the EU, the Trützschler Nonwovens team recognizes the urgent need for more sustainable solutions. Since several years, the Truetzschler core competence is creating nonwoven production lines for sustainable carded/spunlaced nonwovens, which can be used to make disposable wet and dry wipes. When we talk about sustainable solutions in this context, they refer to biodegradable nonwovens that are free from plastic and chemicals, and fibers that come from renewable sources, such as natural fibers or wood-based materials.

Sustainable wet and dry wipes

What are the specific challenges and opportunities related to boosting sustainability for wet and dry wipes? Here are a few key points:

• Carded/spunlaced nonwovens account for a large part of the market for wipes. Truetzschler considers these wipes to be biodegradable if they only contain cotton, natural or cellulose-based viscose or lyocell fibers.

• No chemicals are needed to bond these webs, because bonding takes place using high-pressure water jets to entangle the fibers.

• Wet-laying with subsequent spunlacing are new processes. The main raw material involved is wood-based pulp. Blending the pulp with viscose and lyocell fibers produces eco-friendly wet-laid / spunlaced (WLS) nonwovens. Carded-pulp (CP) composite products are another variety of wipe, which contain a wet-laid pulp and a carded web layer from viscose or lyocell fibers.

• Carded /needled nonwovens make good, slightly heavier wipes for industrial use. Similar to carded/spunlaced wipes, the dry wipe is considered to be biodegradable if biodegradable fibers are used.

• Airlaid and binder-bonded materials contain biodegradable pulp – but they also contain chemical binders. For this reason, the binder content of disposed wipes is a problem that still needs to be solved.

• Spunlaid nonwovens are made from polypropylene or polyester, which are both petroleum-based. In the future, there may be an economically feasible way of recycling these nonwovens –but no such process is available today.

What is nonwoven waste – and why is it challenging for recyclers

Disposable nonwoven products make life more hygienic, safe and comfortable. They are made from a variety of different fibers that are selected based on their suitability for the specific application. Baby diapers, for example, usually feature a top sheet made from ultra-thin spunlaid polypropylene. The acquisition layer (ADL) of these products is typically based on thermobonded bi-component fibers, while the core contains fluff pulp with superabsorber particles. Wet and dry wipes, by comparison, often use viscose or polyester fiber blends or binder-bonded fluff pulp. Cosmetic pads and wound care products use cotton fibers, which are soft and absorbent.

Why are these products difficult to recycle

Mainly because most single-use nonwoven products on the market today were not designed with waste reduction in mind. Instead, they are optimized for functionality and affordability. Diapers are always and wipes are often multi-fractional, and many of these products contain polymer-based fibers like polypropylene or polyester. These materials do not biodegrade, they are incinerated or sent to landfill with other consumer waste. Without effective waste management, these fibers will disintegrate into tiny microplastics – and will eventually enter the environment and stay there for decades.

There are some options for avoiding waste. Recycling works well with non-organic, mono-fractional or separable materials – but is not possible for most disposable nonwoven products. Mother Nature’s recycling system, biodegradation, is another option. In this approach, organic matter like cotton, regenerated cellulosic fibers and pulp is eaten up by bacteria. This leaves nothing behind except water, carbon dioxide gas and the organic component of soil, humus.

Reasons for optimism about biodegradable wipes?

Sustainability is an increasingly important factor when consumers decide what product to buy. However, functionality and performance are still the top priority. If a wipe is flimsy, irritates the skin or tears when taken out of the box, consumers will not buy that product again.

In the next few articles in this Truetzschler series about sustainable nonwovens, they will take a closer look at promising materials and technologies for making sustainable wipes. This will include:

• The latest breakthrough: Carded/pulp (CP) products with a pulp and carded web layer.

• A proven technology for flushable wipes and more: Wet-laid/spunlaced materials made from pulp and regenerated cellulosic fibers.

• A solution for premium markets: Wipes made from cotton and natural fibers.

• Niche products: Nonwovens made from 100 % regenerated cellulosic fibers like viscose or lyocell.