#Nonwovens / Technical Textiles

Highly breathable model of LIVMOA™ disposable personal protective clothing proven to reduce heat stress

Protective clothing normally increases such stress because it shields the body from the surroundings, impeding heat release. Hot environments in which the risks of heat stroke are high make it hard to dissipate body heat from temperature differences with surroundings, so perspiration becomes the prime means for cooling.

Evaporative thermal resistance testing looks at the ease with which perspiration evaporates and the impact on heat stress. The test found that the Wet Bulb Globe Temperature (WGBT) index, a benchmark for heat stress (see note 2), showed a corrected value of 0° for LIVMOA™3000, the same as for regular clothing, and that this Toray fabric lowers heat stress more during work than general-purpose protective clothing The company accordingly believe that its apparel can help guard against heat stroke.

LIVMOA™3000 offers greater air permeability than items with equivalent dust protection capabilities. Testing also confirmed that this product is better than counterparts at lowering heat stress when work movements generate air flows inside the garment.

Toray will endeavor in view of the test findings to help materialize safer and more comfortable work environments by marketing LIVMOA™3000 to the manufacturing and construction sectors, where heat protection is essential in summer.

1. Test Overview

(1) Methodology

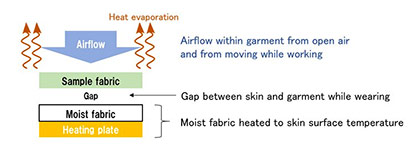

(i) Simulate the internal environment of a garment by laying moist fabric on a heating plate set to same temperature of the skin surface. Place the sample fabric on top and apply a weak breeze to the sample surface.

(ii) Measure heat evaporation through the sample and calculate evaporative thermal resistance.

2) Test conditions

Ambient temperature and humidity: 20°C, 50% RH

Heating plate temperature: 20°C

Wind speed: 1.0m per second

(3)Test items

(i) LIVMOA™3000

(ii) Commercially available single-layered nonwoven fabric protective clothing from other company (Item A)

(iii) Commercially available spunbond meltblown spunbond (SMS) protective clothing from other company (Item B)

2. Test Results

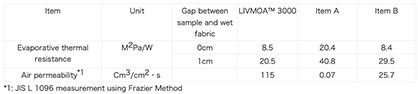

(1) The evaporative thermal resistance of LIVMOA™3000 fabric when there was no gap between the sample and moist fabrics was equal to that of Item B and lower than that of Item A. After placing the sample fabric 1 cm away from the moist one, which is nearer the normal wearing condition, the LIVMOA™3000 fabric had the lowest evaporative thermal resistance.

(2) LIVMOA™3000 delivers the same or less evaporative thermal resistance than to general-purpose SMS offerings with a WBGT index corrected value of 0°C, and is equivalent to a fabric in a garment with a WBGT corrected value below that temperature. In windy conditions, the evaporative thermal resistance of LIVMOA™3000 is lower than that of general-purpose SMS items. Moving while working generates airflows within garments, so LIVMOA™3000 can be expected to reduce heat stress better than items employing general-purpose SMS fabric. To reduce heat stroke risks while wearing protective clothing, it is vital to increase fabric air permeability to wick away perspiration without compromising protection.

Note: Toray conducted this testing under supervision from Associate Professor Tomonori Sakoi of the Department of Advanced Textile and Kansei Engineering in Shinshu University’s Faculty of Textile Science and Technology Department. His work encompasses enhancing thermal comfort and reducing heat stroke risks in interactions between humans, clothing, and thermal environment systems. His efforts include developing new clothing and airflow control techniques for regulating heat and cold, measuring the phenomena of heat and moisture transportation from the body and creating devices for that purpose. He is also developing numerical human body models to predicting body temperature distributions.

Notes

1. Heat stress

This is a general term for the health impacts of high temperatures. The WBGT value evaluates heat stress from hot environments. Exceeding the standard value increases the possibility of heat stroke, necessitating measures to lower that figure.

2. Wet Bulb Globe Temperature (WGBT) index

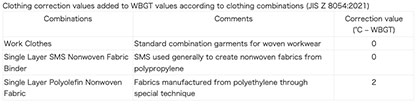

This benchmark for heat stroke prevention, and is derived from temperature, humidity, and radiation from light. This index is recommended for occupational safety and environmental management in the Outline of Basic Measures to Prevent Heat Stroke in Workplaces, which the Labor Standards Bureau of Japan’s Ministry of Health, Labor and Welfare formulated. WBGT correction values are required according to the clothing worn.