#Knitting & Hosiery

New multifunctional RASCHELTRONIC® expands market opportunities

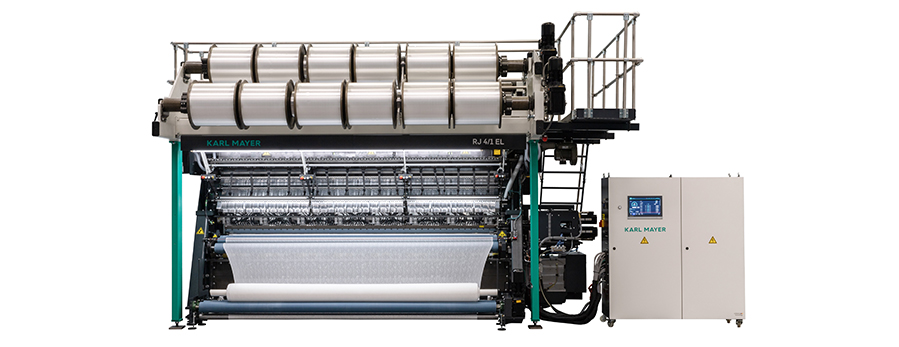

The RJ 4/1 EL sets new patterning standards in the field of four-bar RASCHELTRONIC® machines

Patterns can be changed quickly and easily without any restrictions on repeat length. The equipment with KAMCOS® 2 also makes it possible to work with pattern data from the KM.ON cloud, for even greater speed and convenience in the transfer of pattern data to the machine. In addition to the patterning performance, the output is also impressive. With a speed of 1,300 min-1, the RJ 4/1 EL offers the high efficiency for which the RASCHELTRONIC® series is renowned.

A wide-ranging product portfolio

With its enormous design potential, the RJ 4/1 EL is a breath of fresh air, especially in the lingerie and sportswear sectors. "The possibilities include Spotnet articles and lace-like bands, as before. New for a four-bar RASCHELTRONIC® are multi-faceted patterned satin stripe designs and other lapping changes, which are feasible thanks to the EL pattern drive," says Stefan Gross, Product Developer Textile Technology at KARL MAYER.

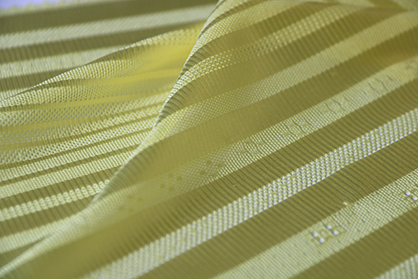

The opulent floral and geometric motifs stand out with filigree mesh fillings and concise contouring that create a subtly sculptural surface appearance. When the split Jacquard bars process bright polyamide in patterns with long and short underlaps alternating, matt-gloss effects are also created, giving the fabrics a touch of extravagance and luxury. Other features of RASCHELTRONIC® articles include a subtle drape, a silky, smooth handle and freecut style for garment production with minimal effort. A 2-needle-overlap ensures the implementation of a firm fabric edge directly on the machine. This can be done by using the GB 3 or GB 4 ground guide bar threaded with elastane.

Performance show during ITMA ASIA

The RJ 4/1 EL is offered in gauges E 28 and E 32 and with a working width of 130?. It was launched for worldwide sales at ITMA 2023 in Milan after a pre-release in China and is a smash hit. Several customers have already invested in the new machine. Interest from manufacturers in China is particularly high.

Many Chinese customers have already seen the new RASCHELTRONIC® machine in the showroom at KARL MAYER (CHINA) in Changzhou City. Processing tests have also been successfully run on it. The next opportunity to get to know it better will be at a product show that KARL MAYER (CHINA) is inviting to its premises from 19 to 23 November, i.e. during ITMA ASIA. Here, RJ 4/1 EL in E 32 will be producing a soft, lightweight lingerie fabric made of polyamide and elastane.

Interested parties are requested to register under the following link:

https://forms.office.com/pages/responsepage.aspx?id=wN-xQvoWVUme0yq53uw9Hp6EVE41oPtGtA5BADYEQ1BUOTVEVDU5VVNKVU5JOFBNOVJMSUlWSDhPSy4u