#Knitting & Hosiery

Organic is sexy

The Corona pandemic is still keeping us on tenterhooks, but the world will returning to normal and consumption. However, a change in customer attitudes is to be expected in the process. Forecasts speak of mindful, social consumption and enjoyment behavior, a return to what is really important.

Does the more conscious behavior of buyers have an influence on the lace business? How is demand changing, and what general trends can be expected?

Ulrike Schlenker from Corporate Communications department at KARL MAYER group asked lace expert Neil Thorpe these and other questions about the future of lace. The managing director and founder of Neil Thorpe Lace Design & Draughting and his team have been developing and drawing lace patterns since 1986, serving a renowned clientele based around the world and with diverse setups.

US: The fashion industry is usually always one step ahead. What season are you preparing right now and what is more important: lingerie or apparel lace?

NT: We are currently focusing on developing patterns for the spring/summer 2023 season. For some of our customers who are market leaders, we are already working on designs for the following season, i.e. for fall/winter 2023/24. The focus is clearly on lingerie lace. Around 80% of demand comes from this sector, with only 20% coming from apparel lace.

US: Many markets are benefiting from catch-up shopping effects in the wake of the abating Corona pandemic. Consumers' lingerie closets are also filling up again. Are there any trends in demand for lace lingerie, for example in terms of design?

NT: In the post-Corona era, there is a strong focus on the twin themes of comfort and sustainability. This shows up more in a shift in thinking than in a trend but it has a big impact on the kind of designs and drawings that are demanded by our customers. Consumers want garments that look and feel soft and environmentally conscious. That's why we're working more on designs with a natural cotton look and drawings that are straightforward to make with more ethically accepted yarns like modal.

US: Is the increasing demand for clothing with a sustainable look also reflected in the color design?´

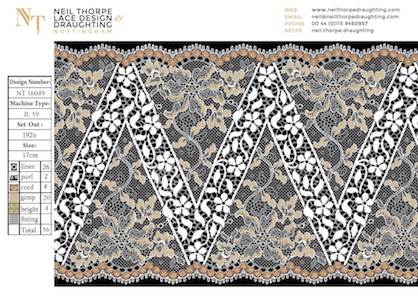

NT: As in every season, the colors our customers choose for their patterns depend largely on their target markets. Nevertheless, as in all areas of the industry, a natural look is required. Fabrics should look as natural as possible. The color scheme plays an important role in this. Beige, white and cream in particular indicate minimal use of dyes and, therefore, give the impression of an environmentally conscious garment.

US: Yarns are just as important as colors in lace design. Which yarn materials will play a role in the coming collections? Are bourdon corduroy designs back in fashion?

NT: Lighter yarns are in vogue, bourdon corduroy designs are less in demand. Due to the aforementioned desire for more environmentally conscious and natural patterns, lighter lurex yarns have fallen a bit out of favor as they are perceived as somewhat plastic. Yarn selection is of vital importance for the future of the lingerie industry. We need a wider selection of sustainable yarns here. That's why we are very pleased to be working with customers who are leading the way in yarn development and producing brand new, super soft, environmentally certified fibers. The cooperation offers us, as the creators of the drawings, a unique opportunity to find the optimal lapping techniques for smooth processing of the latest yarns on the lace machine.

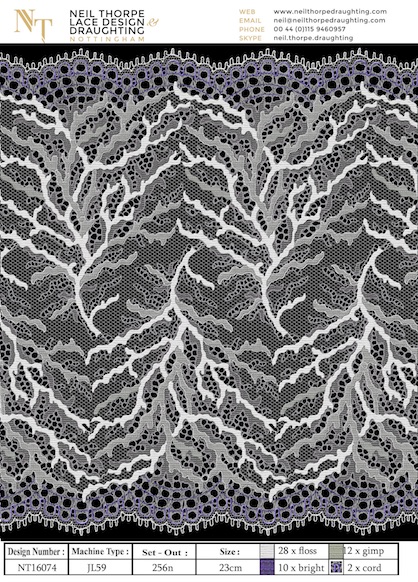

US: Which styles are implemented with these yarns? Are classic lace designs or abstract, geometric designs more popular?

NT: Among young consumers there was and still is some demand for small geometric patterns. In general, however, the trends for the next season are going more towards floral patterns. This became very clear during our visit to the last Interfilière. The desire for less waste and more durable fashion has increased the demand for timeless aesthetics like florals. Of course, the challenge for us is to create classic designs that still excite the modern consumer. For refreshing patterns, we keep the flowers small or medium in size and experiment with sophisticated edge designs and new techniques.

US: Where is the trend heading in terms of fineness? Will fine lace be in?

NT: Our customers have recently opted for some heavier patterns, as crochet and pinhole embroidery patterns are very popular and allow for a high percentage of cotton or similar yarns. However, the trend is definitely towards more delicate patterns. Lightweight yarns, especially in the ground, however, present a particular challenge in terms of environmental compatibility. Therefore, much depends on the development of new fibers and the adaptation of the lapping technique to these fibers when creating our drawings.

US: You work at the interface between the yarn and its processing on the machine, usually on a lace raschel machine. Do you have any wishes for KARL MAYER as the leading manufacturer of these machines in terms of the performance of its offerings? And do you have any wishes for the yarn manufacturers?

NT: Regarding machine performance, we often get feedback from our customers that buyers see the offset pillar stitch for the stitch stop as a flaw in the fabric. We would welcome a new development that offers the proven function without the visual detriment. As for the yarn, a wider, more readily available supply of sustainable yarns is definitely needed to meet the demand for more conscious fashion. As pattern drafters, we would love to see the development of an improved lustrous yarn that, when combined with elastane, is not prone to slipping and looping, as is the case with lurex.

US: Thank you for the interesting interview