#Knitting & Hosiery

Comfortable and sustainable: home and hobbywear made from warp knitted terry fabrics

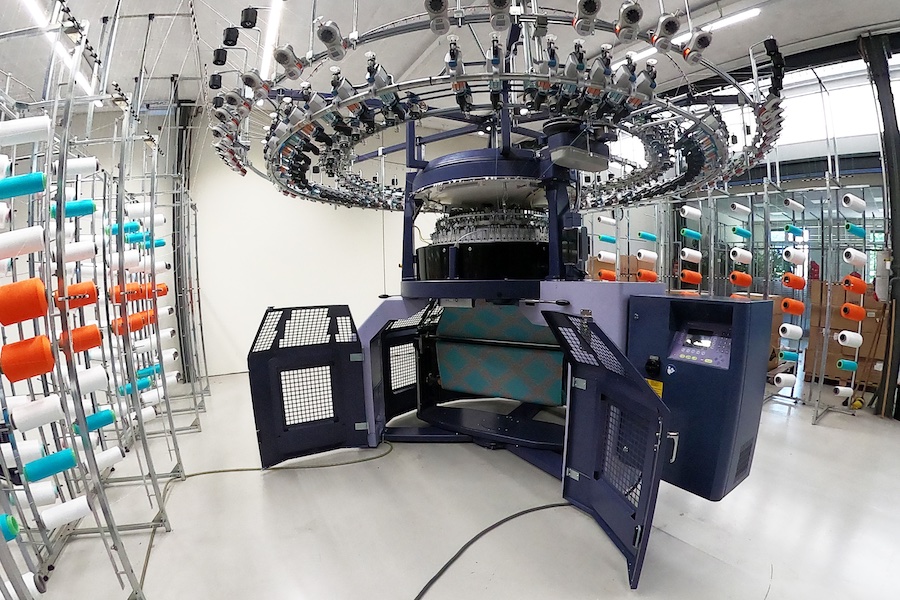

New market opportunities due to goods made of innovative materials and a TM 4-TS EL in a new width

The fluffy textile was produced on a TM 4-TS EL. This terry warp knitting machine is designed for use with staple fibres, and processed the cotton for the shorts in combination with a matrix polyester microfibre yarn. The natural fibre yarn was knitted in as loops on the inside of the warp knitted terry cloth. The large surface area and the inherent properties of cotton give it a high absorbency, while the outside is made of a special man-made fibre yarn with fine fibrils that provide a soft, pleasant feel.

Thanks to the warp knitting technology, the terry loops are reliably anchored into the ground structure by means of stitches. The high loop strength means the item is comfortable to wear for long periods of time with no loss of quality. Given their long life, and also thanks to a manufacturing process that does not require sizing and desizing, terry knitted fabrics represent an ecological alternative to their woven counterparts. As such, the demand for them is high.

In order to support its numerous customers in the terry cloth market, KARL MAYER is always working hard to ensure that its machines and textile products continue to evolve. As recently as June this year, the company launched its TM 4-TS EL with a new working width of 210". Another of KARL MAYER’s latest innovations is a warp knitted terry cloth made using a bamboo yarn.

TERRY.ECO: The ecological way to produce warp knitted textiles

KARL MAYER’s portfolio includes a full range of machines for the highly efficient and ecological production of terry cloth. The range includes warp knitting machines with an integrated brushing system, as well as warping machines for processing filament and staple yarns. These innovative solutions bear the title TERRY.ECO.

Warp knitted terry cloth made in this way is extremely durable and can be designed in a variety of ways. It can be used to produce absorbent cotton towels, as well as heavy towel qualities with weights of up to 600 g/m² and double-sided terry cloths. In particular, terry warp knitting machines with an electronic guide bar control system make loop-free areas possible for creating striped patterns, finished edges and small checks. What’s more, the lengths of the towels, the patterns, and the terry loop pile height can easily be changed within a fabric.

Besides being chic, warp knitted terry articles also offer ecological benefits. The TM 4-TS EL model for processing staple yarns consumes approximately 87% less energy per kilogram of fabric produced than air-jet weaving looms, since it does not require any electrical power to generate compressed air. Also, no sizing process is required. This saves on textile auxiliaries, effluent and energy costs – to the value of about 0.20 US dollars/kg, or roughly 30% of the production costs for the grey fabric (excluding the yarn).

In addition to this, the TM 4-TS EL impresses with its improved efficiency. With a width of 186" and a speed of 800 rpm, the innovative model produces around 1,800 kg of terry cloth weighing 400 g/m2 per day when used in 24-hour operation. Its output is therefore approximately 250% higher than that of an air-jet weaving loom. Combining the TM 4-TS EL with the ISO COTTON direct warping machine is a particularly effective way of giving customers maximum efficiency when producing warp knitted terry cloth made of cotton.

Larger working width, greater output

The TM 4-TS EL has become even more productive with the latest extension to its working width, from 186" to 210". Similar to its narrower counterpart, the super-wide model achieves a speed of 800 rpm and is also offered in gauges E 24 and E 28. Thanks to its higher gauge and fabric density, it can be used to produce premium-quality towels, which are currently in demand in China.

Since the beginning of this year, China’s home textile exports have been rising rapidly. According to an internal survey at KARL MAYER, customer numbers have increased by around 54% in the first half of 2021 compared to the same period last year. This upward trend is expected to continue until the end of the year, and is mainly a result of the COVID-19 pandemic. In the wake of this globally rampant and highly infectious disease, people are staying at home and taking more interest in their own four walls. As part of the home textiles business, the towel market is also benefitting from this.

For a long time, terry cloth bathroom items were considered low-price in China. This attitude has changed in recent years. On the one hand, improved living conditions have led to an increase in quality requirements, frequency and willingness to pay for towels. On the other hand, the growing trend towards customisation has led to new demands for use. Nowadays, customers increasingly expect their towels not only to offer good drying properties, but also to be colourful, stylish and feel pleasant to the touch, all while offering consistent quality.

In light of the shift from a price-driven market to a quality-driven one, the TM 4-TS EL 210" in E 28 offers many competitive advantages. As such, it was no surprise that the newcomer drew plenty of interest when it was launched at an in-house show at KARL MAYER (CHINA) during ITMA ASIA + CITME in June 2021 (Fig. 2). The machine’s equipment includes a beam attachment of 3 x 40" and 1 x 50", as well as KARL MAYER’s carbon technology, which ensures high temperature stability in particular.

Yarns made from bamboo viscose, greater variety in sustainable materials

COVID-19 is confining people all over the world to their homes and causing demand for comfortable leisurewear to soar. As a result, product developers are working hard as well. In order to cater to the demand for feel-good outfits, a cosy terry fabric has been created using a yarn obtained from bamboo cellulose, thus also reflecting the trend towards sustainability (Fig. 3). The natural fibre material forms soft, absorbent loops that are densely arranged on the inside of the textile. The outside is made of a polyester microfibre yarn that creates an ultra-soft fleece layer.

A sporty set comprising a hooded jacket and jogging trousers – made from this innovative double-faced material – was presented at KARL MAYER’s booth at ITMA ASIA + CITME in June 2021, where it attracted a great deal of attention. The warp knitted terry cloth was also an important topic at a company webinar held shortly after the exhibition.