#Knitting & Hosiery

New TM 3, 290", promotes economic recovery of warp knitting in China

The bestsellers include various velour articles, suede leather or articles with a cotton look. „With its performance and competitive price, the new TM 3 is the right machine, at the right time, in the right place“, explains Lin Tailai, Head of Tricot Machinery at KARL MAYER.

According to the official national statistics office in October 2020, the gross domestic product rose slightly by 3.2 % in the following three months and significantly by 4.9 % in the third quarter compared to the previous year, after a 6.8 % decline in the first quarter. The good economic mood had an impact on investments. Warp knitting companies also regained confidence in the market and began to order new machines.

More performance, lower price

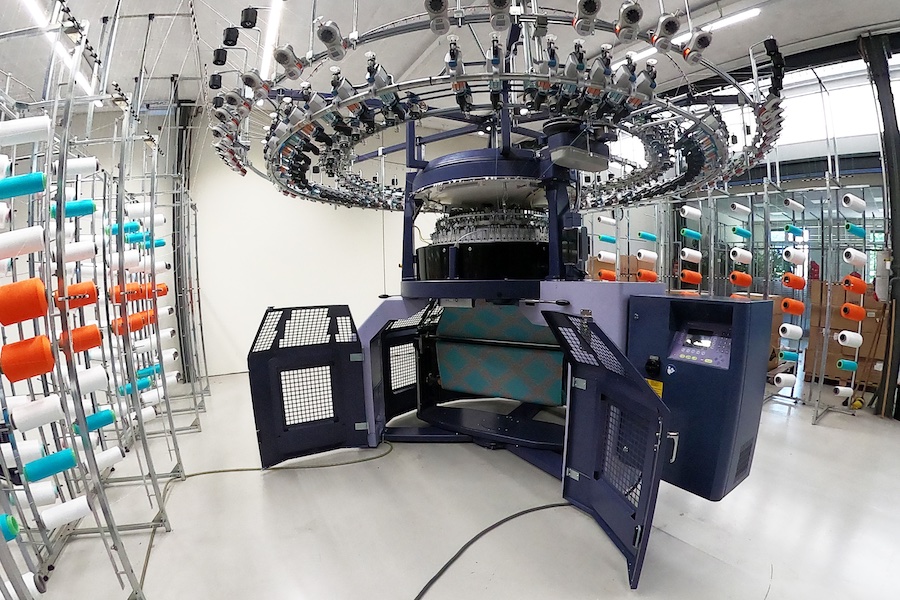

At ITMA 2019, KARL MAYER’s HKS 3-M ON was successfully introduced to the market as high-tech model of the latest tricot machine generation. With the TM 3, the basic machine range will follow in the generation change. The new TM 3 is characterized by a further optimized price-performance ratio. With a working width of 280", which can be extended by 10", it is much wider than its predecessor with 180" and/or maximum 186" and just as fast. So, the output is clearly higher. „The first field test machine already showed a stable machine run over several months at an operating speed of 2,200 min-1. The efficiency could be doubled compared to the previous TM generation, at a more attractive price“, says Lin Tailai to the success factors of the newcomer. The extra width available also increases flexibility when producing several fabric lines. The number and width of the textile strips can be varied in a higher band width. The TM 3 offers further versatility thanks to its ability to process elastane.

For this purpose, the standard version is modified by an optional unit for the guiding and tension monitoring of the elastic yarns in the ground guide bar GB 3. In particular for the manufacturers of elastic velour articles this equipment variant might be extremely interesting. As a further option, the standard 32" beam superstructure for the ground guide bar GB 1 can be replaced by an 40" variant when using DTY yarns.

The longer running length maximizes the beam change intervals and, thus, minimizes downtime. In addition, like all machines of the third generation, the new TM 3 offers the features of KAMCOS® 2 and the advantages of bars made of carbon fiber reinforced plastic. The high-tech material is extraordinarily light and provides a temperature stability that meets the requirements of the high working width. The spring elements of the tension rail could also be optimized by a solution of fiber-reinforced plastic. The result of this improvement is maximum effects when compensating yarn tensions and, thus, a smooth yarn run-in as an important prerequisite for an exact fabric appearance. The machine with the extraordinary performance at an excellent price is offered in gauges of E 28 and E 32. The patterning is done by an N-gear.

Good reputation from field tests

An important step on the way to the start of series production of the new TM 3 was the feedback from the field during the pilot phase of development. „With Hua Huang Knitting Clothing Co Ltd. we chose the right customer for our field tests. The manufacturer in Tongxiang City, Province Zhejiang, gave us great support and helped us promote the machine with his positive attitude“, emphasizes Lin Tailai. A good cooperation and the explanations of the field test partner are generally important for the acceptance of innovations in the market.