#India ITME 2016

New iNTERSPARE Krantz Syncro for the Indian company Jubilee

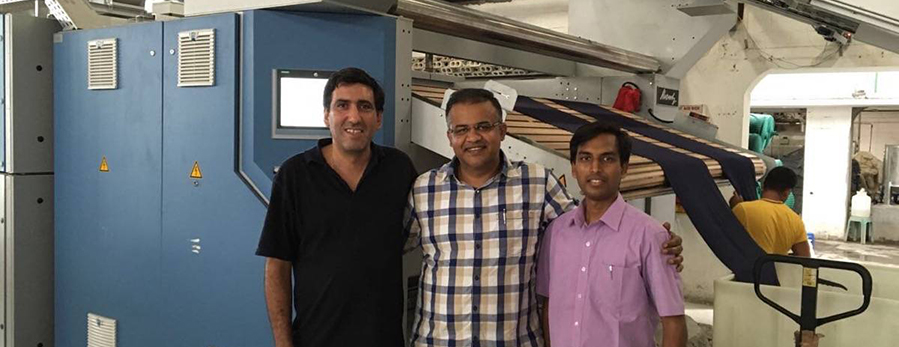

“We were more than happy when we saw at the ITMA in Milan the Krantz Syncro is back. Furthermore iNTERSPARE has presented themselves as an excellent partner from the start and now we know that it was the right decision to work with them”, says Mr Balu, Managing Director of Jubilee.

The iNTERSPARE Krantz Syncro shrink dryer has always been an excellent example for German engineering creations. In particular, the extraordinary quality of the results and the high production rate, based on the optimal interplay of many sophisticated and patented components, cause the Syncro is considered by experts as the best shrink dryer in the world.

The advanced next-generation iNTERSPARE Krantz Syncro exhibited at ITMA was adapted to current market trends and customer requirements by iNTERSPARE. An example are next-generation circuits and control units which improve operation even further. Further modifications address the increased demands for sustainability and energy efficiency. Here, iNTERSPARE has expanded the Syncro with numerous particularly energy-efficient next-generation components.

“We decided to buy an iNTERSPARE Syncro because it stands for an extraordinary quality and also high productivity. The new dryer will help us to reach our high goals in the market and is an important investment to accelerate our growth and to fulfill our customer' s demand for best quality of the fabrics”, says Mr. Balu.

Jubilee needed the Syncro for its facility in Tirupur, in particular for the production of delicate knitted products of various compositions, as well as for a range of products in the premium segment.

The Syncro’s variety was therefore also very important to Jubilee. Without problems it is possible to drive with one or more slim or wide fabric layers side by side. Additionally processes such as drying, shrinking, intermediate drying or drying for formation of fabric can be proceeded here on only one production line. The shrink dryer allows long reaction times and high overfeeds up to 200 % on the screen belt. This causes a uniformly and gentle drying with an optimal stress relieving in the fabric.

Depending on the type of product, the operator can choose between a high-pressure air jet or ventilated drying. The intensity of the air flow can also be adjusted as desired, and likewise the qualities of the characteristics. Because of these different selection possibilities of many parameters the drying can be regulated exactly for each special requirement of the fabric.

The deal between Jubilee and iNTERSPARE was agreed as far back as the ITMA in Milan and the business was concluded shortly thereafter. Once Jubilee had finished preparations - which involved extending the site and building a new hall - the Syncro was then transferred in August.

“We are very pleased that Jubilee has opted for the newest version of the Syncro, and that just a few months later we are able to announce the first successful launch of the Syncro in India” says iNTERSPARE CEO, Dirk Polchow. He adds: “Jubilee is the kind of customer that every company likes to do business with. Open-minded, very focussed on quality, innovative and eager for knowledge. We sincerely hope that business relations between our two companies will continue for years to come. Thanks must also go to our new agents, Global Group of Marketing and Global Group of Engineering. They are excellent partners to promote our machines in India and Sri Lanka!”

Mr Balu is of the same mind: “We are very comfortable with the collaboration with iNTERSPARE and also estimate the outstanding know-how they have shared with us.” Thanks to the good relations with Jubilee, the system has since also successfully been used to carry out product tests for other companies.

Pic: The iNTERSPARE Krantz Syncro in operation at Jubilee in Tirupur/India