#ITMA Asia + CITME 2024

In-house show at KARL MAYER (CHINA) during ITMA ASIA + CITME in Changzhou

Double presence at the leading trade fair

At KARL MAYER (CHINA), visitors can look forward to a broad exhibition of warp knitting and flat knitting machines from the Group's product portfolio and textile trends. The event starts on October 13 and has a highlight in store: On the opening day, the KARL MAYER GROUP's new showroom at its location in China will be inaugurated with solutions from all areas of technology.

Warp knitting machine customers can look forward to the performance demonstration of a total of seven machines. “We will be showing both proven high-tech machines and some completely newly developed mid-range machines. The aim is to demonstrate our technological leadership to our customers worldwide and to provide them with solutions in various price categories,” says Christof Naier, President of the Warp Knitting Business Unit.

Representatives of the three-bar HKS and TM series will be on show, including an HKS 3-M ON PLUS in gauge E 18 and a 4th generation TM 3 with a working width of 290”, a TM 2-SE in E 36, the new TEXTRONIC® Lace MT 84/1/40 S in E24 and the likewise new Raschel machine RE 4-1 in E 36. In the double raschel area, the new mid-range machine DM 6/2-6 EN will be launched, which impresses with its excellent price-performance ratio. An exclusive textile and application show will provide inspiration for new business and ideas for product development. The main focus will be on highly comfortable outdoor outfits, sun protection textiles, leavers-like lace, casual wear, powernet, shoe fabrics and warp-knitted silk fabrics. The latest Care Solutions products, including the myKM.ON customer portal and the Energy Efficiency Solution for tricot machines, will also be presented in Changzhou, as well as Service4you for the latest generation of remote support.

For the flat knitting sector, the entire range of STOLL machines will be presented for the various customer requirements. Among the machines on show will be a CMS 530 in the new gauge E20 to produce fine, high-quality articles and a CMS 503 L ki in E3.5.2, which, with a working width of 50?, can produce designs with large motif formats as well as articles with an extended size range. Another highlight is the CMS 703 ki knit and wear in E9.2. This all-rounder produces fully-fashion and finished articles and also offers more scope for size design. The diversity of the product world of STOLL flat knitting machines will be demonstrated by a textile innovation show with inspiring patterns, trendy fashion items and the presentation of the new STOLL trend collection NOCTURNO.

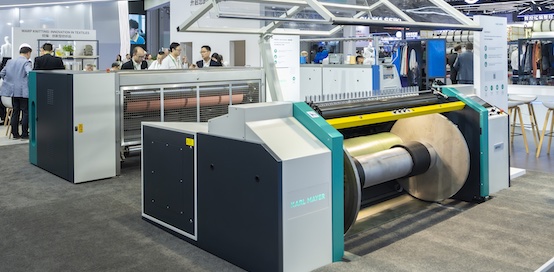

For manufacturers of technical textiles and producers of conventional articles looking for new business opportunities, a warp knitting machines with weft insertion offering excellent value for investment will be presented. A 2nd generation TM WEFT, 247?, which sets new standards in the production of lightweight warp-knitted fabrics with weft insertion for outerwear fabrics and interlinings, will be on show.

KM.ON will be showcasing innovative digital solutions for mastering current challenges. With Digital Production Management (DPM), the software specialist has a game-changer product for store floor organization in the warp knitting industry in its exhibition program. The new development offers seamless monitoring and control of production processes in real time as a basis for optimizing operational processes. The Quality Monitoring System (QMS) for quality management on warp knitting machines will also be presented. The revolutionary AI-based solution is more reliable and more precise in detecting faults than conventional systems and is easier to use. STOLL PPS powered by KM.ON enables greater efficiency in flat knitting. With the tool for controlling, planning and optimizing production, reaction and lead times can be shortened and adherence to deadlines improved. The web-based solution is also available anywhere and at any time. The innovative products of the CREATE family, including the software solutions CREATE DESIGN and CREATE PLUS, which significantly accelerate the development, design and production process for knitwear, will be presented to speed up the workflow from idea to market launch.

The new showroom is seamlessly integrated into the in-house show. The ultra-modern competence and creative center provides visitors with an exclusive selection of textile highlights, trend themes and innovative solutions from all business units of the KARL MAYER GROUP on an area of 480 m².

Warp knitting customers will find the latest tricot and RASCHELTRONIC® fabrics for sports and casual wear, exclusive lace articles and spacer fabrics, especially for the footwear sector. In a digi-tal area, the software specialist KM.ON will be presenting its innovations for warp knitting and flat knitting. The Technical Textiles division will introduce pioneering examples from the wide range of textile products offered by its multiaxial machines and warp knitting machines with weft insertion, and KARL MAYER warp preparation business unit introduces itself with a video presentation. STOLL takes up the largest space in the new showroom with its TexLab. In addition to numerous machines at work, trendy fashion models and popular patterns will be presented.

Registration for the in-house show and booking of a bus transfer is possible under the following link: https://forms.office.com/pages/responsepage.aspx?id=wN-xQvoWVUme0yq53uw9Hp6EVE41oPtGtA5BADYEQ1BUMkdPQUZCSU5QT0RNNzQ2UEdPRFpLV1AyRS4u&route=shorturl