#ITMA Asia + CITME 2024

Swedish machine builders meeting the needs of a changing market at ITMA ASIA + CITME 2024

China’s mills, for example, currently consume more than 50% of all of the world’s fibres and its synthetic fibre manufacturers are responsible for over 70% of global production.

To meet their sustainability goals, many leading brands are now looking for the incorporation of even higher percentages of recycled fibre into the yarns that their products are made from.

“Many Chinese cotton spinning companies have been processing yarn mill waste for decades using rotor spinning technology, which is best suited for recycled yarns that contain a high short-fibre content,” says TMAS Secretary General Therese Premler-Andersson. “In the past, the practice of incorporating a percentage of recycled content into yarn blends has not been anything to do with meeting sustainability goals, but simply about achieving an acceptable quality with the cheapest available fibres. Now, however, these mills are in the position of potentially being able to charge a premium for yarns containing higher recycled content.”

According to the Zurich-based International Textile Machinery Association (ITMA), China has installed just under four million new rotor spinning spindles since 2015.

The potential is huge and this industry-wide development puts high demands on changing and adopting production with upgraded technologies not only in spinning, but also further up the production chain, something that TMAS members are well aware of and prepared for.

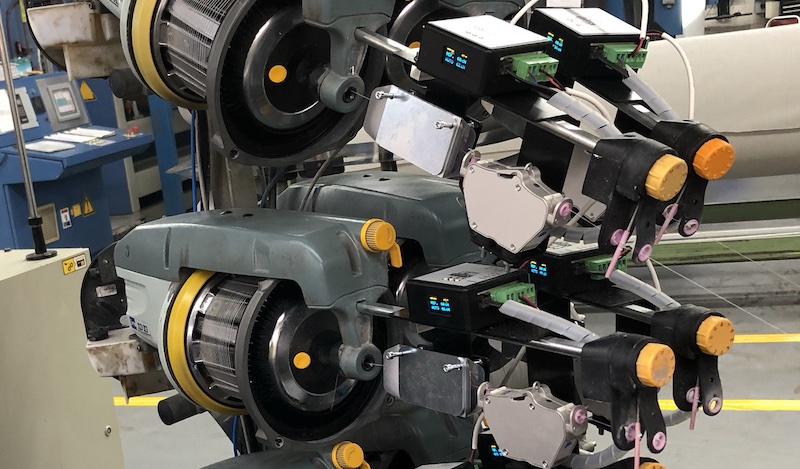

Eltex ACT-R for weaving looms

The subsequent weaving of yarns with recycled content requires special consideration, which is where TMAS member Eltex, with its ACT-R technology, can help.

The Eltex ACT-R is a stand-alone device designed to automatically keep weft yarn tension at a constant and required value on rapier weaving machines.

“This is especially important when weaving with recycled yarns because the quality of the yarn packages can be much more irregular,” says Eltex Senior Sales Engineer Daniel Sauret. “Shorter staple fibres result in inconsistencies and are prone to breakages, but the ACT-R system automatically compensates for any differences in weft yarn tension that may originate from such irregularities, regardless of whether the yarn package is full or almost empty.”

The ACT-R is designed to be fitted after the prewinder, and can be used on any type of rapier machine, regardless of its age.

“Our ACT-R is a completely plug and play, stand-alone system and self synchronizes without any communication with the weaving machine,” explains Eltex CEO Brian Hicks. “This is important, because many older weaving machines are still in operation worldwide, and the ACT-R enables instant improvements to be made without upgrading these machines in any way. We have achieved fantastic results for weavers working with recycled yarns who have been amazed at the difference in consistent quality and uninterrupted production that can be achieved.”

As a pioneer in the adoption of electronic sensors by the weaving machinery industry, Eltex of Sweden is marks its 60th anniversary this year.

That the company’s timeline aligns with the acceleration of weaving machine production speeds from around 150-200 picks per minute back in the 1960s to up to 1,200 picks per minute today is no coincidence – Eltex sensor technology has made a significant contribution to enabling today’s fault-free, high-speed production.

Vandewiele’s accumulated know-how

Advanced weaving control is also the bedrock of business for Vandewiele Sweden AB, which benefits from all of the synergies and accumulated know-how in fabric formation of the market-leading textile machinery builder Vandewiele Group.

The company supplies its weft yarn feeding and tension control units for weaving looms to the majority of the leading weaving machine manufacturers around the world, as well as for retrofitting in working mills, and will present its latest X4 yarn feeders with integrated accessory displays at ITMA ASIA + CITME 2024.

X4 feeders are available in three different versions – with an integrated

tension display (TED), with integrated active tension control (ATC), or with rapid tension control (RTC).

With TED, a manual setting of the weft feeder’s brake ring is digitally shown as a value that can be transferred to other weft feeders located on other weaving machines. It also displays alarms when they occur, for easier visibility. With ATC-W, the position of the S-Flex Tensioner is constantly monitored by an internal sensor – maintaining tension through the full weaving cycle to reduce waist and to improve the fabric quality, Machine learning AI. The Rapid Tension Control (RTC) is a fast reacting, programmable weft tensioner system. It allows “within-the-pick” adjustment to different tension levels, achieving the optimal tension required for the complete weft insertion cycle. The system requires only one device to be set for the weft tension. The integrated panel is easily used for electrical opening and programmable settings.

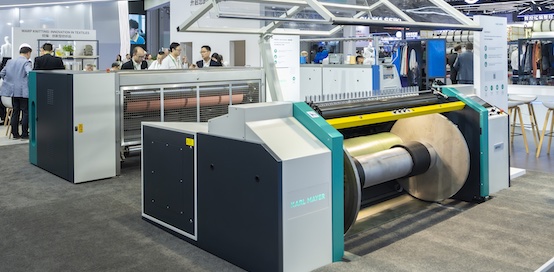

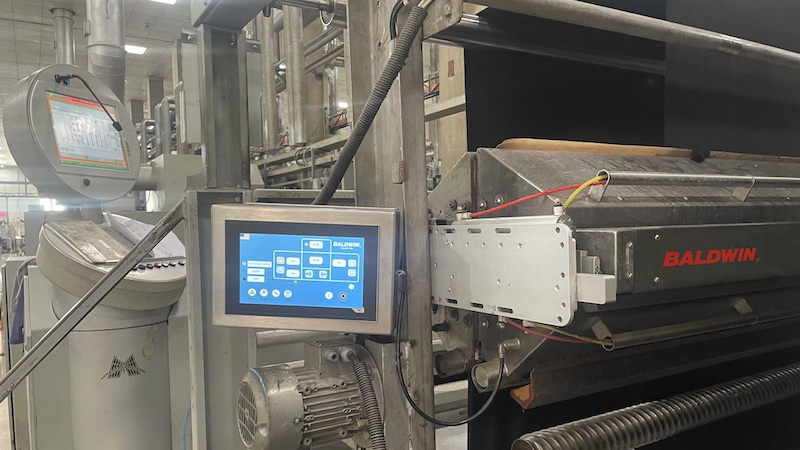

TexCoat G4 for faultless finishing

TMAS member Baldwin is meanwhile revolutionising the traditional water and energy-intensive pad-dry-cure finishing process with its TexCoat G4 unit.

The TexCoat G4 precisely applies chemistry, including softeners, antimicrobials, durable water repellents, flame retardants, resins and most other water-based chemicals across a textile’s surface only where it is required, on one or both sides of the fabric. The system can therefore reduce water, chemistry and energy consumption by up to 50% compared to traditional pad application processes.

Baldwin already has multiple installations in China adding fluorocarbon-free durable water repellents to technical fabrics, including one in partnership with a major European sporting goods retailer.

Baldwin has further just announced a collaboration with Monforts, the German leader in dyeing and finishing equipment and Archroma, the manufacturer of, among other leading products, fluorocarbon-free durable water repellent finishes.

A full-width Baldwin TexCoat digital spray unit is currently being installed on a stenter frame at the Monforts Advanced Technology Centre (ATC) in Mönchengladbach, Germany, to enable extensive trials to be carried out on an industrial scale.

“We strongly believe that this partnership will be greater than the sum of its parts,” says Rick Stanford, Baldwin’s Vice-President of Business Development for Textiles. “Together, we will support dyeing and finishing manufacturers in their development projects, boosting the quality and performance of their finished products, while at the same time maximising the productivity and resource utilisation of the finishing application process. This is the first time our three companies have committed to working together with a focus on bringing transformative change to the dyeing and finishing space. It will result in significantly lower energy, chemical and water consumption with increased productivity and higher quality for fabric finishers.”

“We are really looking forward to being in Shanghai again and connecting with customers old and new to present Swedish innovations for the good of our customers as well as the planet,” concludes Therese Premler-Andersson.