#ITMA Asia + CITME 2018

China turns increasingly to superior quality weaving machines from DORNIER

(Photo: “Weaving mill”; Source: DORNIER)

Audacious investment objectives, rising wages, enormous funds for research and development (equivalent to about 226 billion euro in 2017 alone) and emerging aspiration towards quality: China's evolution from the overflow production facility for the West into a high-tech industrial powerhouse in its own right shows no signs of flagging. This trend is also reflected strongly in the Chinese textile industry, and is being monitored attentively at the Lindauer DORNIER GmbH (LiDO): "China has always been an important market for us, but since the demand for higher quality textiles has also begun to grow, it has become our biggest market", says Wolfgang Schöffl, Head of Business Unit Weaving Machines at DORNIER.

In China, LiDO weaving machines are used to create fine scarves and elegant women's apparel from cashmere wool and silk as well as intricate airplane parts from carbon fibers. This last category is part of the growing global market for technical textiles, which is supplied with special coatings, airbags, tirecord and filters as well as much else which is manufactured in the Middle Kingdom on weaving machines from DORNIER. And the volume of these high-performance fabrics required just to satisfy China's domestic demand is enormous.

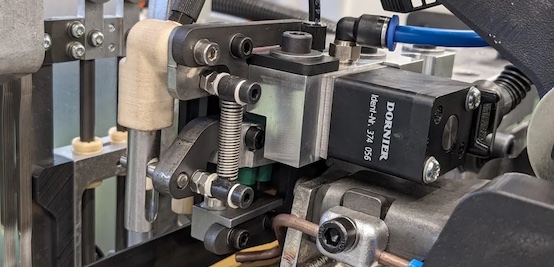

Flawless processing of high-performance fibers

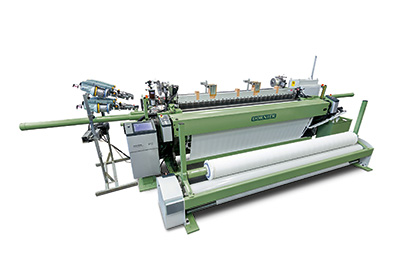

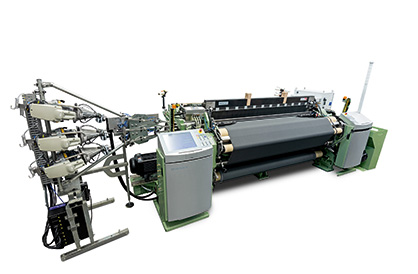

Let us consider filtration, for example: The fact that the Chinese city of Xi'an cleans its air with the tallest anti-smog tower in the world (100 m) is convincing testament: cleaning air and water is a major concern in China. And this is one reason why DORNIER in Shanghai – for the first time ever in Asia – will exhibit its new P2 rapier weaving machine in its most powerful configuration (Type: TGP). This machine is able to bring a reed beat-up force of up to five tons for producing wide, seamless fabrics for high density air and water filters. "The textile is exposed to exceptionally high forces specifically for wet filtration; seams are weak spots, which should be avoided if possible", explains Schöffl.

It is no coincidence that the rising sales of weaving machines from the shores of Lake Constance are closely linked to Chinese demand for high-performance fabrics both domestically and for export: The weaving machines from DORNIER have represented the gold standard for flawless processing of high-performance fibers such as carbon, glass fiber and aramid for over 60 years. "The greater the volume of high-quality fabrics China manufactures, the more weaving machines we can send them", says Schöffl. At the same time, the division head continues, besides the technical quality the company's Chinese customers also value LiDO's aftersales and training services, ease of contact and fast response times.

"Made in Germany" weaving machine showroom

Besides the P2 TGP rapier weaving machine, DORNIER is also going to exhibit other machines at the trade fair: an air-jet weaving machine for manufacturing car upholstery and an airbag weaving machine (at the stand of the Belgian machine building company Van de Wiele) will also be on display. The "Made in Germany" label is highly regarded as a hallmark of quality in China, as is borne out by an ongoing project in the town of Ürümqi. An entrepreneur has established a showroom there with a dozen or more weaving machines to show how raw textile materials are turned into fabrics for an enormous variety of applications. Naturally, in such a setting the quality of the wovens cannot be left to chance: Every one of the weaving machines in the showroom was built by DORNIER in Lindau.