#ITMA 2019

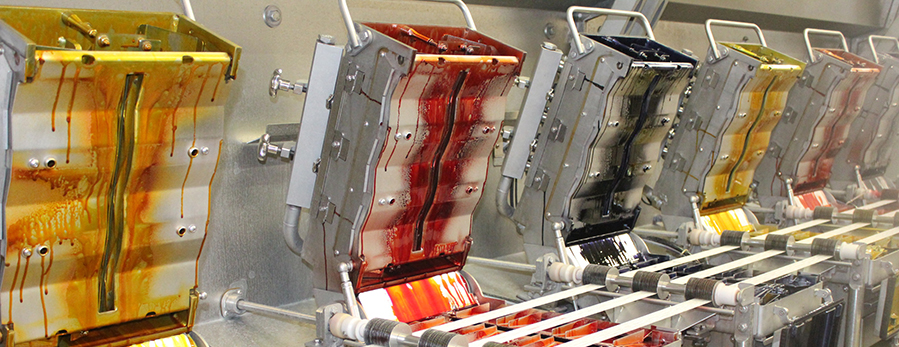

Superba’s new MCD/3 space dyeing machine at ITMA 2019

Suberba leads the field in heat-setting machines, having installed more than 350 of its TVP3 lines for all types of carpet yarns, whether polyester, polypropylene, polyamide PAN, wool or blends. A further 80 LV3 models for acrylic yarns are also now successfully running at carpet plants around the world.

The latest MCD/3 space dyeing machine is meanwhile capable of handling a layer of 72 ends with an unequalled range of spot length – especially for the ultra-short spots of below 25mm.thus enabling “one-pile/one-color” process on the carpet.

In combination with a TVP3 heat-setting line, it can space dye polyester or polyamide yarns with up to six colours and also allow special dyeing effects such as bi-colour printing to be achieved. For acrylic yarns, the MCD/3 can similarly be combined with Superba’s new high capacity DL/5 setting line.

Further synergies are possible with Vandwiele weaving or tufting machines, with all technologies now being equipped for machine-to-machine interaction and learning, as part of the company’s comprehensive TEXconnect programme. The company’s sensors, software programmes and servers have become increasingly sophisticated and the real-time data from different machines – across connected manufacturing sites and across different countries and even continents – can be collected and shared.

Digital models of both machines and production processes can be created and analysed for the optimisation of production settings, to vastly improve scheduling and planning and also make considerable savings on raw materials and energy.

For carpet manufacturers, all of this is leading to the creation of truly Smart Factories.

Further Vandwiele innovations to be unveiled by the company at ITMA 2019 will include:

- The new RCE2+ Rug and Carpet Expert weaving machine – a truly digital workhorse, with all yarns continuously controlled and measured and the difficult bobbin changes of the past completely eliminated due to Vandewiele’s latest Fast Creel.

- The new VSi32 Velvet Smart Innovator jacquard, in combination with the latest Smart Creel, for the production of Italian velvet – combining the potential of flat woven jacquard fabrics with pile yarns leading to the potential for the creation of whole new range of fabrics for the home and for fashion.

- The INCA (interlacing by non-continuous air) system for BCF extrusion systems – a new method for intermingling BCF yarns which greatly improves tangle knot uniformity for significant cost savings.

- The Vandewiele Cobble Colortec L+, which is now the most versatile tufting machine available on the market.

- A range of jacquards from Vandewiele Bonas, demonstrated across ITMA 2019 above flat weaving machines from the industry leaders, as well as Vandiele’s own RCE2+.

- The completely revised Titan 5540 carpet finishing machine from Vandewiele Titan, which is now able to accommodate carpets with straight, round and complexly-shaped corners simultaneously.

- The Vandewiele Protechna Arraycam 5420 optical inspection system which is suitable for monitoring standard fabrics on all common tricot warp knitting machines.

- The latest IRO-ROJ weft insertion technologies.

Superba is at stand D206 in Hall 6 at ITMA 2019, while the Vandwiele Group’s main stand is in Hall 4, stand A206, at ITMA 2019.