#ITMA 2015

Santex Group at ITMA 2015

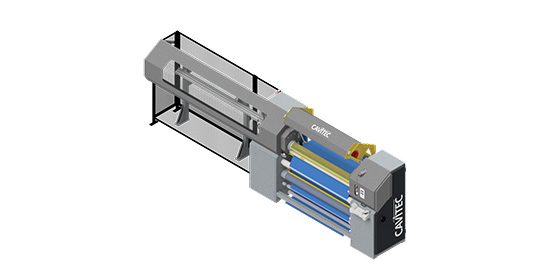

Cavitec stands for high-end machines for coating, laminating, impregnation and is the first choice of prepreg suppliers. The Swiss firm, part of Santex Rimar Group, presents – first time to the public – the redesigned Caviscreen at Techtextil Frankfurt. Caviscreen features latest technology attaining unparalleled results for breathable laminates and offering an interesting cost bonus.

Sustainable compacting with Compas is the environmentally-friendly route to controlled shrinkage. Sperotto Rimar’s revolutionary compacting technology brings unmatched results without adding chemicals.

The Cavitec high-performance portfolio of coating, laminating and impregnating solutions is now extended with the launch of a two-in-one machine featuring rapid switching between rotogravure and full-surface coating. Its technological superiority of the new Cavimelt Pro – based on hotmelt adhesive application – delivers bonding performance which meets the highest expectations for quality and sustainability.

With POY 2.0, Barmag is introducing a completely redesigned spinning concept that takes the production of partially oriented yarn (POY) to a new level in terms of technology and economy. The solution, which was presented to a selected audience of experts for the first time at ITMA Asia + CITME 2025, was met with great enthusiasm: several yarn producers worldwide immediately expressed their interest in a pilot plant.

As a highlight of the JEC, the Institut für Textiltechnik (ITA) of RWTH Aachen University will be presenting hydrogen pressure tanks manufactured using multifilament winding processes at the NRW joint booth in Hall 5, Stand G65.

DyStar, a leading specialty chemical company with a heritage of more than a century in product development and innovation, announced today the appointment of Ruan Cunfan to its Board of Directors, effective 20 February 2026.

Textile‑to‑textile recycling leader Circulose joins Spinnova’s ecosystem (consortium) to help advance the scale‑up of Spinnova’s technology. Spinnova has actively sought partners to accelerate commercial scale‑up, and Circulose, as a key player in textile recycling, strengthens the ecosystem by providing a raw material that is in high demand across the industry.