#Nonwovens / Technical Textiles

The compacting revolution

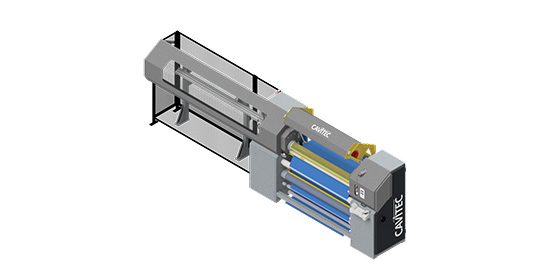

Compas: maximum effect, minimum environmental footprint

Compas is an open-width compacting and finishing machine for knitted and woven fabrics, which uses a unique compacting concept. This is based on a belt with specific elasticity characteristics, which enhances the fabric compacting process.

Revolutionary and effective

The belt is set to a control level of pre-tension and the fabric contacts the belt at the point when it is at its maximum tension. When the tension is released and the belt returns to its original position, the fabric follows, so that it is compacted lengthwise.

This compacting revolution guarantees optimum compacting capability for both knitted and woven fabrics. Outstanding residual shrinkage values are achieved with all fabric types, including extremely difficult ones such as 100% viscose knitted and woven articles. Finishers are amazed by the natural stretch effect on the fabric warp achievable on 100% wool worsted fabrics and end-users appreciate the silky and smooth touch which has become a recognized feature of Compas.

Compas is compact

The design of the Compas system enables easy handling of all machine operations – especially the tension control applied to the fabrics, which is critical in compacting processes.

During operation, fabrics are warm and somewhat humid and are subject to lengthwise tensions which can severely impact the results. The Compas configuration ensures very short distances between machine elements. Even the pin tenter controlling the fabric width is integrated into the main body of the machine. This minimizes the distance between the point where the fabric leaves the pins and the compacting section, where the lengthwise shrinkage is actually imparted.

The compactness of the machine also limits energy consumption, unlike systems comprised of several separate units where both energy and steam requirements are increased dramatically.

Innovations with an ‘eco-attitude’

The Compas pin tenter has a V-shaped steaming unit which follows the fabric so that steam is applied only where fabric is running. That means the steam is exploited to maximum effect, without wasting energy.

Sperotto Rimar developments are designed to express the company’s stated ‘eco-attitude’. The sophisticated technology of Compas embodies this policy, by empowering more sustainable finishing with a closed-loop cooling circuit to save precious water. Indirect rubber belt cooling enables recycling with totally unpolluted water. This contrasts with conventional compacting machines using standard rubber belt technology, which can consume up to 4 cubic meters of water per hour.

Another plus comes from the fact that water is not sprayed directly onto the compacting belt, avoiding water absorption by fabric being processed. This responsible use of water further underlines the eco-attitude.