#ITMA-Asia + CITME-2016

Reiners + Fürst presents its premium rings and travellers 'Made in Germany' at ITMA Asia 2016

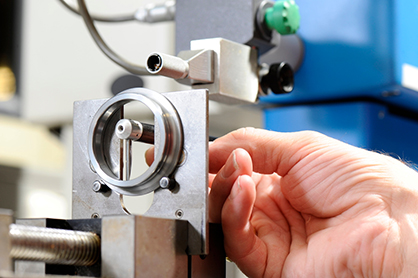

Pic: R+F spinning rings in the production process

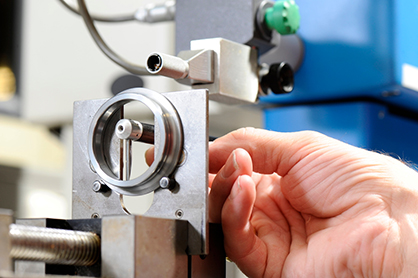

Pic: R+F ring travellers in the production process

Pic: R+F spinning rings in the production process

Pic: R+F ring travellers in the production process

With POY 2.0, Barmag is introducing a completely redesigned spinning concept that takes the production of partially oriented yarn (POY) to a new level in terms of technology and economy. The solution, which was presented to a selected audience of experts for the first time at ITMA Asia + CITME 2025, was met with great enthusiasm: several yarn producers worldwide immediately expressed their interest in a pilot plant.

As a highlight of the JEC, the Institut für Textiltechnik (ITA) of RWTH Aachen University will be presenting hydrogen pressure tanks manufactured using multifilament winding processes at the NRW joint booth in Hall 5, Stand G65.

DyStar, a leading specialty chemical company with a heritage of more than a century in product development and innovation, announced today the appointment of Ruan Cunfan to its Board of Directors, effective 20 February 2026.

Textile‑to‑textile recycling leader Circulose joins Spinnova’s ecosystem (consortium) to help advance the scale‑up of Spinnova’s technology. Spinnova has actively sought partners to accelerate commercial scale‑up, and Circulose, as a key player in textile recycling, strengthens the ecosystem by providing a raw material that is in high demand across the industry.