ITM 2013

Itema at ITM 2013

One single brand, an exhibition to demonstrate state-of-the-art technology and unparalleled competence of diverse weaving applications

With many years of success, the result of this collaborative effort is an important milestone for the company and a benchmark of unparalleled quality and excellence for the global weaving industry. Following a successful and sustained market penetration, Itema believes the official launch of the R9500 in the Turkish market will represent clear confirmation of this new course with Itema being the focus of participation at Istanbul ITM 2013.

Important results have already been achieved in terms of sales for the new Itema machines in Turkey. The first installations have already provided repeat orders in both insertion systems: Air jet and Rapier. Customers illustrate their satisfaction by honoring Itema with the trust of repeat orders in different sectors and applications like bed-sheeting, upholstery, and home furnishings.

Notwithstanding, strong demand continues among the most revered Turkish companies for the Projectile machine, with significant sales in denim and technical sectors. Business Manager Corporate Communication, Juerg Kundert, says: "The Turkish weaving market is one of the most important markets for Itema and the primary goal of Itema's presence at ITM 2013 is to showcase the unparalleled quality of its new products to the Turkish customers. Our customers are our partners, their success is our mission!"

The Products and Services

R9500 Rapier Weaving Machine: Exceeding the expectations of rapier weaving performance!

With the widest application range, the R9500 is the backbone of Itema. It is simple to operate and maintain producing unsurpassed quality providing the highest added value of Itema products.

Highly versatile, the R9500 enables the customer to target new opportunities and quickly penetrate new markets. The simple, yet comprehensive, design of the New Common Platform (“NCP”) allows easy control of all technical parameters of the weaving machine.

Radical developments of the drive and transfer system provide a more robust machine which insures a consistent, high speed transfer at the lowest vibration pattern. Wide interchangeability of mechanical and electrical parts with the A9500 Air Jet weaving machine reduces operational costs for customers having both technologies. A modern machine offering the latest technology for remote access and control, strategically designed for easy use and integration into the most challenging environments.

Alpha PGA Rapier Weaving Machine - Upholstery is my business!

Thanks to the universal PGA gripper, the weaving flexibility of the Alpha PGA weaving machine has been greatly developed and enhanced. The Alpha PGA is the most flexible machine with regard to inserting different weft materials and yarn counts into the same fabric (e.g. upholstery). This provides more flexibility, higher efficiency of production and convenience for style changes. The Alpha PGA is a machine that weaves an unlimited range of fabrics and materials at a high production level.

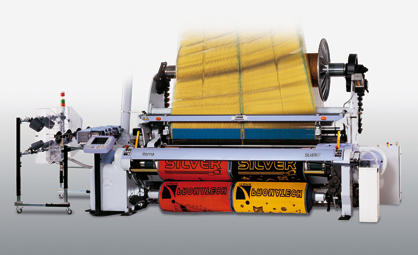

Silver 501 - The workhorse of Itema!

Itema’s new rapier weaving machine – Vamatex Silver 501 is the strategic evolution of the highly successful Silver HS model. Based on the same footprint and complete with a new electronic plat-form, the Silver 501 is specifically engineered to handle demanding styles or heavy weight denim at the highest production speeds with superior quality. Key developments of the drive and transfer systems provide a more robust machine that insures a consistent, high speed transfer at the lowest vibration pattern. The ease of use, maintenance and operation synergies remain to provide a transition free integration for weavers and technicians alike.

With long experience in the manufacturing of terry weaving machines, Itema is the most famous brand in the world for terry rapier weaving machines. The superior technology of the Silver DT has been proven in the market all over the world. The Silver DT is the best solution to produce high quality terry products.

R880 - Can weavers afford to be without it?

The R880 is the result of the long-standing experience in the construction of rapier weaving machines of the internationally renowned technology and machinery provider Itema. With its unmatched performance, the R880 rapier weaving machine sets new standards for productivity in fabric forming. Its unique rapier drive system carried out by the tried and tested Propeller delivers the increased output of this latest weaving machine technology. Very strong steel side frames together with rigid and sturdy cross-members result in highest stability and lowest vibration.

With a machine speed of up to 550 picks per minute and a maximum weft insertion rate of 1200 meters per minute, the R880 is unrivalled within its league.

A9500 Air jet Weaving Machine - Weaving top quality with highest performance!

The new A9500 Air Jet Weaving Machine: Itema defines a new benchmark with dependable, high speed performance, consistent fabric quality and versatility enabling the customers to embrace rapidly changing market expectations. A significant percentage of mechanical and electronic parts are now fully interchangeable with the rapier models, thus reducing spare parts cost for customers using both air jet and rapier technologies.

With a full-color touch screen, the New Common Platform (“NCP”) is the perfect tool to optimize machine settings with an immediate impact on quality, while also reducing air consumption and waste. Service Software is available for remote access, control and diagnostic support if neces-sary. Without exception, the A9500 is State-of-the-Art but also User-Friendly.

A9000 Air jet Weaving Machine - Best price performance air jet weaving machine!

Assembled at Itema Weaving Machinery (China) near Shanghai (a factory working under the high-est quality control policy) the A9000 air jet weaving machine is based on the same Swiss engineer-ing and design used for the Itema air jet weaving machines made in Europe.

The A9000 excels in low power and low air consumption with a weft insertion rate of 1600 meters/minute. The R&D engineers of Itema developed this new machine with a strong frame, re-duced parts and state of the art electronics. Further convincing characteristics are the low mainte-nance and ease of operation. Strategically equipped and offered worldwide to weave competitive, commodity applications at the highest speeds at a lowest cost.

P7300HP Projectile Weaving Machine- Widest weaving width for technical fabrics!

The P7300HP V8 projectile weaving machine needs little introduction. It is a further development of the P7300HP and is targeted towards future marketing needs. The sum of the technological advances once again confirms the superiority of the projectile weaving machine technology. The low energy consumption, its versatility and the outstanding adaptability to the ever changing market make the projectile weaving machine a safe investment with excellent return on investment. The projectile weaving machine is best suitable for technical fabrics.

CWT "Customized Weaving Technology" - Tailor-made weaving machine construction to produce special fabric & production requirements!

Industrial textile production calls for modern, high performance weaving machines. The principle of Customized Weaving Technology is to supply all customers with weaving machines tailor-made for their products. For instance, CWT covers weaving machines for agrotextiles and geotextiles, conveyor belts, sail cloth, cinema and theatre screens, filter fabrics, tarpaulins and so forth. This enables their customers to conquer new markets.

CWT applications are the first choice for heavy industrial textiles:

- large weaving widths up to 655 cm

- reinforced construction

- beat-up force up to 15,000 N/m

LoomBrowser

The Itema LoomBrowser is a software package that brings all production data and setting data present in the weaving machine to the PC. The company describes it as follows: "Just install the LoomBrowser on the PC of your choice to monitor efficiency, change & download machine settings, create or download new weft and dobby patterns. Merely click on the machine of your choice within the machine layout to gain access to all machine information as if you were standing at the machine itself."

Upgrades and modifications

We can support you with low cost upgrades to produce a wider range of fabrics, increase the performance, the quality of fabrics or, to produce different fabrics which could not be woven so far. Many customers are taking advantage of the proven and existing modification kits, many others are contacting us with special requests, ideas or needs.

Please do not hesitate to discuss individual solutions with us. Itema will gladly assess and study the technical possibilities and feasibility of such projects.

Active Textile Services – Anything, Anytime, Anywhere

ITEMA announced that they want to become top class as a service and spare parts provider. "We want excellence in this field with an unchallenged reputation for quality. Your machines must perform and produce the best quality fabrics; your mill must be profitable. We can provide valuable advice, improve the preventive maintenance system and reduce spare parts consumption. We offer textile technical consulting to fine tune the preparation and weaving processes.

A specialist is available at your door step - speaking the same language - in the same time zone. It is of the utmost importance, especially in these dreary times, to provide quick and quality service to you, our esteemed customer. "

It is what it is – the Original

The fully automated spare parts centre located in Zuchwil/Switzerland quickly processes all spare parts orders for Itema weaving machines.

The Itema EDOSnet web based ordering system allows customers to manage their spare parts in an efficient way. With EDOSnet they are in direct contact - online and round the clock - with the central spare parts distribution centre in Switzerland. Customers have access to the industry's best and most comprehensive spare parts warehouse for all Sultex, Somet and Vamatex weaving machines.

The Itema ELSPACE electronic spare parts catalogue

With the electronic spare parts catalogue customers can easily and reliably determine which spare parts they need and can also print out drawings and spare parts lists.

Itema will exhibit the following products at ITM 2013:

- Itema R9500 (220cm / Staubli 3060): Rapier Machine for Denim

- Itema R9500 (230cm / Staubli 3060): Rapier Machine for Shirting

- Itema A9500 (280 cm / MAF 1661): Rapier Machine for Bed Sheeting

- Itema R9500 (190cm / Bonas Si 11): Rapier Machine for Furnishing & Tapestry (Bonas Booth)

- Itema Silver DT (360 cm / Grosse EJT-4): Rapier Machine for Terry Towel (Grosse Booth)