#Weaving

Itema at SITEX 2025: on show the complete weaving machines range to producing Saree fabrics

Sameer Kulkarni, Itema Weaving India Managing Director commented: “Exhibiting at Sitex, in the cradle of the Indian Saree production, is for Itema the perfect occasion to showcase our technological solutions tailored to weaving these traditional and sophisticated fabrics. For many years, Itema has been the leading provider of high-end rapier machines to Surat weavers mainly due to the superior textile versatility of our weaving technology and to the timely, accurate and customer-oriented service which is the trademark of Itema India.”

Itema exhibits two weaving machines at Sitex 2025 equipped with different rapier weft transfers with the target to demonstrate how Itema weaving technology is capable to answer to any textile and production need of this specific fabric segment:

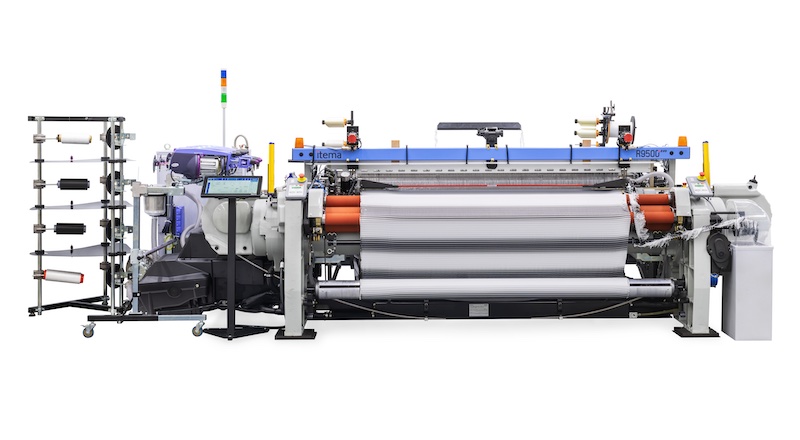

The Itema Rapier R9500EVO on display at Stäubli Booth (Booth 230)

In the partner booth, the Itema Rapier R9500EVO in 3800mm weaving width is equipped with the Stäubli Jacquard LX PRO with 12.000 hooks. The machine is configured to reach the highest textile performances thanks to the Itema FPA EVO Free Positive Approach Weft Transfer featuring a race board with no guiding elements in the shed and to the Itema MiCUT Motorized Weft Cutter.

The FPA EVO Rapiers ensure to perfectly handle the widest range of weft yarns allowing weavers to weave with endless creative possibilities even the most sophisticated and complex fabrics and combines the versatility of a positive rapier system with higher performances and efficiency.

With the FPA EVO Weft Transfer System, thanks also to the combination with the MiCut Motorized Weft Cutter, it is possible to weave the widest range of fancy, multifilament, metallic, and monofilament yarns, including lurex and fancy yarns widely used in Saree fabrics production.

Moreover, the FPA EVO Weft Transfer System ensures a gentle treatment even of the most delicate warp yarns, leading to the renowned Itema fabric quality.

The Itema MiCUT Motorized Weft Cutter allows to set an independent cutting time for each weft directly from the machine console and represents the ideal solution when weaving complex styles and multiple weft configurations, providing unbeatable versatility and textile efficiency.

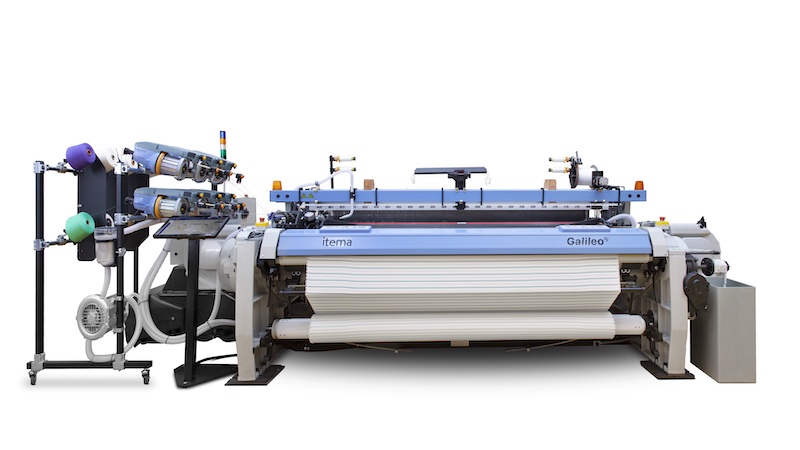

The Itema Rapier Galileo-RX on display at Itema Booth (Booth 258)

On show in the booth is the Itema Rapier Galileo-RX in 3800mm weaving width and equipped with the Qihui Jacquard QH5376 GT. The Itema Rapier Galileo-RX represents an undisputed market success that over the last two years conquered Surat weavers trust thanks to its reliability and to the best price-quality ratio. The machine is configured with the new Itema EVOConsole with touch, full glass, capacitive display, offering wi-fi and Bluetooth connectivity and ready for data analysis and IoT functionalities. Equipped with the Itema SK Weft Transfer System with guided hooks in combination with the MiCUT Motorized Weft Cutter, the Galileo-RX will weave a Saree fabric with nylon warp yarns and polyester and lurex weft yarns.

To find out more about Itema weaving solutions, the references in the market, and the case histories, make sure to visit the Itema booth 258 at SITEX Surat International Textile Expo 2025.