ITM 2013

GROZ-BECKERT at ITM TEXPO EURASIA 2013

In the Knitting sector productivity will be the central topic. The customers will be shown saving potentials that arise only out of the use of Groz-Beckert products. Already slight improvements of the central influencing parameters lead to a more efficient production. Based on this, the use of innovative Groz-Beckert solutions opens up further chances to increase productivity. A prominent example is the circular knitting needle litespeed®, which combines conservation of resources, cost-saving but also significant increased performance. Due to the optimized needle shank geometry, this needle allows enormous energy savings and a considerable reduction of CO2 emissions compared to standard needle. Also the revolutionary high-speed solution contributes to higher productivity. Because of the needle modification large diameter circular knitting machines can now produce with higher speed. In practice, the cheek geometry of these needles has been optimized and the latch speed dramatically reduced, which leads to significant less needle breakage and wear. Furthermore Groze-Beckert developed the CylinderMaster a unique system for the cylinder change at large diameter circular knitting machines. The handling is so safe, fast and simple, that the cylinder change can be easily done by one person.

In the weaving sector the tying machine KnotMaster will be displayend, moreover the new high performance heald frame as well as the leno system PosiLeno® are key topics at the trade fair. This exemplifies Groz-Beckerts status as a full-range supplier, who covers the preparation as well as accessories and ensures process reliability in each production step. Based on the motto „Increase in productivity starts in the weaving preparation“, the KnotMaster convinces with sophisticated technology and simple operation. It is fast, universally applicable and can knot even very fine warps.

The heald frame ALtop HYBRID® with aluminium profile is based on innovative lightweight construction and shows a uniquely high bending resistance of the heald staves. Due to that, it is suited to the dynamic stress of fast running weaving machines and allows the production of perfect woven fabrik. The positively controlled leno system PosiLeno® enables a 100 percent higher fabric production compared to conventional leno systems. It thereby shows less wear at healds and doup frames, despite the higher speed.

In the Nonwovens sector, Groz-Beckert presents the new EcoStar needle. The universal felting needle, that can be used in almost all applications, is a special nonwovens highlight and the first result of the Innovation Initiative. Compared to standard needles it offers an improved surface quality of the end product and longer service life. Other benefits are reduced energy consumption and lower penetration force, but the same effiency. Also on show will be the GEBECON® needle, which is designed to provide an ideal combination of good surface quality of the end product plus the beste possible bending resistance. The newly-developed HyTec® D Jet Strip for hydroentangled products is adapted for the application in spunlace systems, in terms of both hardness and durability, and provides numerous advantages. Examples are the nozzle edges with improved wear resistance, reduced energy consumption due to optimised nozzle edges and much more. Groz-Beckert also offers solutions for the handling of needle boards and needle inserting with the Board Master System, which has a fast and efficient needle inserting system known as NeedleMaster, and BoardScoot, the user-friendly needle board wagon for safe transportation of needle boards.

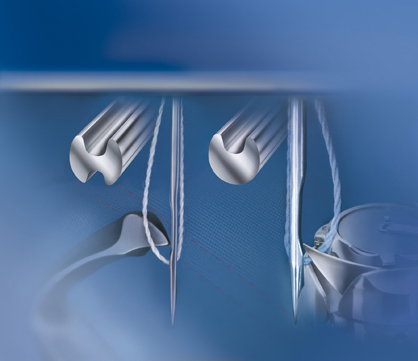

In the sewing sector, Groz-Beckert continuously works on developing the perfect needle for every requirement. The innovative needle geometry LoopControl® of chain stitch and lockstitch needles helps to form perfect loops. The needles with distinctive roundings are gentle on the material and cause less needle breakage and damage of needle points, in addition, the seam apparence is improved. Groz-Beckert also holds availabe needles for fine and finest materials or for material that is extremly difficult to sew. The special application needles SAN® 10 and SAN® 10 XS guarantee higher quality through best possible protection of the sewn material and contribute to the increased productivity. Besides the comprehensive product range and excellent availability, Groz-Beckert stands for further customer-specific services. These include trainings, workshops, sales support as well as competent consulting and especially solutions for sewing technology problems.

Groz-Beckert is the world’s leading provider of industrial machine needles, precision parts and fine tools as well as systems and services for the production and joining of textile fabrics. The products and services support the fields of knitting, weaving, felting, tufting and sewing. Founded in 1852 the company today employs around 8,000 people and has a turnover of over € 500 Mio. Groz-Beckert operates with agencies, production and distribution subsidiaries in more than 150 countries around the world.