#Textile processing

The sewing machine needle manufacturer with process expertise

Groz-Beckert impresses with comprehensive knowledge and experience in the sewing sector

Groz-Beckert is a major player in the textile world, with a history of over 170 years. In the past 40 years its Sewing product area has established itself as a leading manufacturer of sewing machine needles. Based on decades of experience and the commitment to top quality standards, Groz-Beckert offers its customers more than just a wide range of high-precision sewing machine needles. In addition to application-related advice, the portfolio also includes INH Quality Management, which makes a significant contribution to process optimization and digital transparency in sewing operations. With its comprehensive services and innovative digital solutions, the company has become a one-stop partner to the global sewing industry.

The sewing machine needle as core product

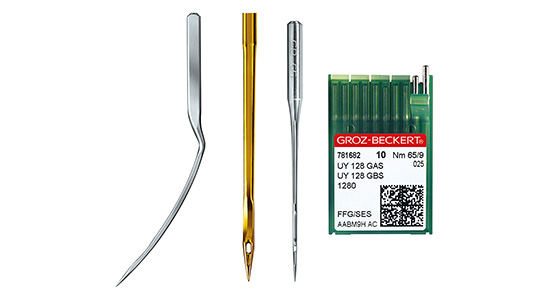

The sewing machine needle represents the core product of the Sewing product area of Groz-Beckert. The needles are manufactured to meet the high requirements of today's textile industry. They are characterized by an extraordinary durability and their ability to deliver reliable results even in demanding sewing operations. One example that stands out is the GEBEDUR needle: Thanks to its special coating, it offers increased protection against wear and damage, which significantly increases the efficiency of the production process in sewing plants.

For particularly challenging sewing applications, Groz-Beckert offers so-called Special Application Needles (SAN). They are specially designed for complex sewing operations or for processing specific materials. They include SAN 10 and SAN 10 XS for fine to ultra-fine fabrics, SAN 6 for sturdy denim fabrics, and SAN 5.2 for technical textiles.

In addition to these special solutions, Groz-Beckert offers a wide range of standard needles. With a variety of needle sizes and different point styles, the right needle can be found for every application. This diversity not only provides a high degree of flexibility, but also helps to ensure a consistently high quality of the end product.

Comprehensive advice and targeted knowledge transfer

With its global network of sewing laboratories and application engineers, Groz-Beckert offers its customers comprehensive support with all challenges related to the sewing process. If difficulties arise, customers can rely on the company's experts. On site or in their own laboratories they carry out detailed analyses and develop customized solutions. The aim is to achieve sustainable improvements in the customers' production processes and the quality of their end products. This includes targeted training for customers and their employees to deepen their knowledge of sewing machine needles and avoid potential problems before they occur.

The expert knowledge that Groz-Beckert has built up over decades is not only used internally but is also actively passed on to interested parties. The Customer Portal is a central platform for this, offering a wealth of product information and valuable insights into the world of sewing machine needles. This knowledge is also made available through public webinars and informative videos. Over 5,000 professionals use the Needle Finder in the Groz-Beckert Customer Portal, which allows to quickly and easily find the ideal needle for a variety of sewing applications.

Innovative solutions for more efficiency and transparency

Groz-Beckert not only supports its customers in the actual sewing process, but also considers the entire process chain around the sewing machine needle. Particular attention is paid to compliance requirements that brand owners and buyers are placing on sewing companies. With INH Quality Management, Groz-Beckert offers an innovative solution that precisely addresses this issue. With software and hardware components, INH enables the digital documentation of all needle changes, ensuring maximum transparency. This eliminates the need for time-consuming manual processes, significantly increasing efficiency and optimizing workflows in sewing plants.

The aim is to digitally map all processes involving sewing machine needles – from ordering and storage to routine needle changes. With its holistic approach, Groz-Beckert will continue being a reliable partner not only with needles but also with innovative solutions that sustainably improve the efficiency and transparency of the sewing process.