#Dyeing, Drying, Finishing

Monforts, Archroma and BW Converting’s Baldwin Technology partner to drive innovation in sustainable textile finishing

Leading-edge equipment, technology and chemistries converge to push boundaries on sustainable solutions at Monforts Advanced Technology Center in Germany

Together, the three companies will support dyeing and finishing manufacturers, a critical part of the textile supply chain, in their development projects, boosting the quality and performance of their finished products, while at the same time maximizing the productivity and resource utilization of the finishing application process.

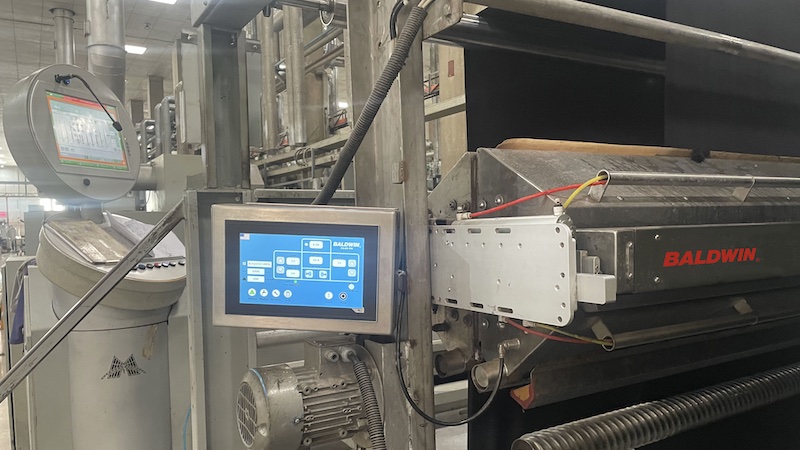

Kicking off the partnership in the second half of this year, Monforts will install BW Converting’s full-width Baldwin TexCoat digital spray unit on a stenter frame at its Advanced Technology Center (ATC) at its headquarters in Mönchengladbach, Germany.

“Our ATC already houses two full Montex stenter finishing lines engineered to accommodate an extremely diverse range of processes, in addition to a Thermex range for the continuous dyeing of denim and other woven fabrics, a full color kitchen and a number of lab-scale systems for smaller batch trials,” explained Monforts Junior Technologist Saskia Kuhlen. “It enables our customers to test their own textiles and technical fabrics under fully confidential, real production conditions and using the results from these trials we are also able to make recommendations for improving many fabric finishes. The new TexCoat installation will make an important contribution to what we can achieve.”

TexCoat G4 revolutionizes the traditional water- and energy-intensive pad-dry-cure finishing process by precisely applying chemistry including softeners, antimicrobials, durable water repellents, flame retardants, resins and most other water-based chemicals across the textile surface only where it is required, on one or both sides of the fabric. The system can therefore reduce water, chemistry and energy consumption by up to 50% compared to traditional pad application processes.

The TexCoat G4 installation brings together the surface functions, fabric transport and thermal processing technology of Monforts stenter frames with Archroma’s specialty chemicals, applied with TexCoat’s contactless precision, to achieve optimum absorption and maximum efficacy, exceeding the performance of traditional pad applications.

“Archroma’s commitment to advancing sustainability solutions for technical textiles has led to a pivotal partnership with Baldwin, where the benefits of contactless precision spray combined with our innovative solutions have helped textile manufacturers achieve greater energy and water savings,” said Michael Schuhmann, Global Marketing Segment Manager for Technical Textiles, Archroma Textile Effects. “We are thrilled to take the partnership to the next level with the integration of a renowned equipment expert. Together, we will bring the best of our expertise in sustainable technologies to our customers around the world.”

“Baldwin has enjoyed a great relationship with Monforts and Archroma over the last few years,” added Rick Stanford, Baldwin’s Vice-President of Business Development for Textiles “Individually, we are working hard to assist our customers to achieve their sustainability and environmental targets but this is the first time the three companies have committed to working together with a focus on bringing transformative change to the dyeing and finishing space. It will result in significantly lower energy, chemical and water consumption with increased productivity and higher quality. We strongly believe that this partnership will be greater than the sum of its parts.”

Beyond textile finishing, Monforts, Baldwin and Archroma will work together to develop a versatile offering that will include coloration concepts and in the not-too-distant future the partners additionally plan to expand their collaboration to continuous spray dye applications developed by Baldwin.