#Denim

Itema returns to Denim Première Vision with iSAVER® technology.

Developed by Itemalab®, the Itema Group independent company dedicated to product and process innovation for the whole industrial sector, iSAVER® eliminates the waste selvedge on the fabric left-hand side by inserting the weft without the need of additional yarns, thus significantly reducing raw materials and water wastage.

Thanks to the iSAVER® devices installed in worldwide denim mills to date, an average annual savings of 600 tons of cotton and 12 billion liters of water can be achieved, while, from an economic perspective, an average of €2,000 per loom per year can be saved.

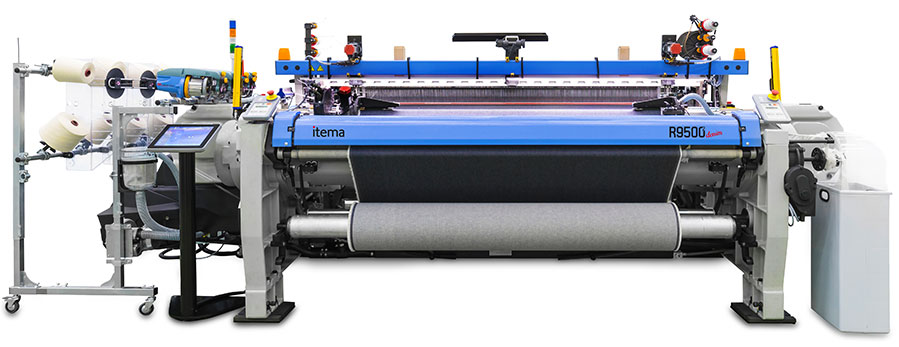

In the denim sector in particular, Itema offers iSAVER® on the R9500-2denim rapier machine, already present in the weaving rooms of major denim manufacturers worldwide.

Prominent among them in terms of production volumes are ISKO, Sharabati Denim, and Prosperity Textiles: giants that weave hundreds of millions of square meters of denim each year, confirming the long-term reliability of Itema’s technologies.

“We are proud to collaborate with the industry’s most important leaders, meaning that the scope of our innovations grows in concert with their high manufacturing capabilities,” stated Ugo Ghilardi,

CEO Itema Group. “Through these partnerships we can truly influence the market by bringing sustainability to the heart of the supply chain, a goal shared by all those who choose to invest in our technologies to make a difference, optimizing the production and preserving the resources and the planet.”

A difference that industry professionals will be able to experience firsthand at Denim Première Vision, delving into the concrete benefits of iSAVER® to elevate the quality and sustainability of their performance.