#Denim

RUDOLF OFFUEL ®: 'It's Time to Get Wasted'

RUDOLF is turning 100 years old this year. Quite frankly though, it’s difficult to find a quiet moment to celebrate. The past 18 months have taught us how rough things can get and how quickly they can change. The shortages of raw materials, gas and oil are having dramatic consequences. Because of geo-political situations and because of petroleum being a scarce resource, we can expect even more dramatic supply bottlenecks in the future.

This unsettling scenario was the “inspiration” for RUDOLF OFFUEL®, a progressive array of chemical auxiliaries for denim finishing consisting, by at least 90%, of alternatives to crude oil and/or components based on recycled materials. OFFUEL® meets two pressing needs of society: the definition of sustainable industrial practices rooted in renewable sources and the identification of economic alternatives.

Finishing auxiliaries from waste

One of the most advanced and progressive frontiers of textile chemistry, is the transformation of waste (natural or not) into substances that can be further used in a greener and more sustainable world. Until not long ago, waste of any origin was an unconceivable raw material for the chemical industry due to poor consistency and availability issues. Nowadays, through the upcycling of organic waste and the chemical recycling of plastics, RUDOLF can present the denim industry and society with another option: textile finishing auxiliaries from renewable raw materials and waste.

RUCOGEN® UPCYCLE RNB is the crown jewel within the OFFUEL® range. It’s a dispersing agent, specific for denim washing, based on chemically recycled, PET plastic waste. It’s about the upcycling of post-consumer, disposable PET plastic bottles into valuable textile chemistry.

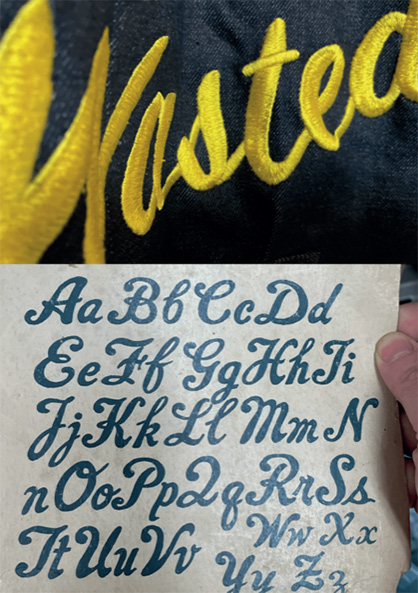

Celebrating the company’s 100 years with the 'It's Time to Get Wasted' collection

The OFFUEL® Collection, designed by Labor Made Inc, is a series of modern denim icons reused, reworked, reimagined and, of course, finished with OFFUEL® products. These styles can be worn across gender and have a natural unisex feel and style. The collection is focused around the Japanese word 'Mottainai' - meaning "Don't waste what is valuable:' “The intent behind the collection is refining on how we embrace waste and discarded materials” says Gordon Muir of Labor Made. “Then we turn them into beautiful items that embrace today's modern culture and sustainable values”, he adds.

The Kaihara fabric has its highest possible pre-consumer waste content, the pocket bags are made from vintage Japanese yukata and the back patches are recycled and reprinted. Everything is hand made using the best local, Japanese craftsmanship and traditional skills.