#Composites

More ecology and economy thanks to natural fibre composites and knit to shape products

At this year's leading industry trade fair from 5 to 7 March, the company will be exhibiting with KARL MAYER Technical Textiles and its STOLL Business Unit in Hall 5 at Stand K 32 in the Parc des Expositions in Paris Nord Villepinte.

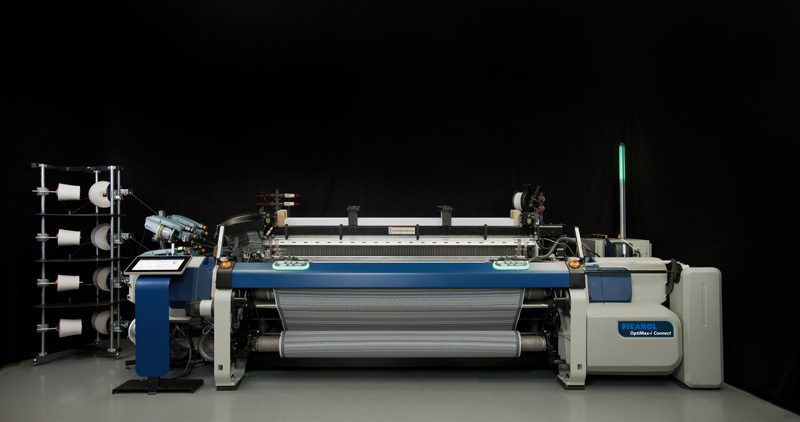

One focus of the exhibition will be non-crimp fabrics and tapes made from bio-based yarn materials for the reinforcement of composites. Last year, KARL MAYER Technical Textiles had already shown exhibits in this area and hit a nerve: Under pressure from the looming climate crisis and rising energy prices, the composites industry is constantly looking for sustainable solutions. "While our business with multiaxial and spreading technology for processing conventional technical fibres such as carbon or glass continues to do well, we are seeing increasing interest in the processing of natural fibres into composites. That's why we have a new product in our trade fair luggage for the upcoming JEC World: an alpine ski in which, among other things, hemp fibre fabrics have been used," reveals Hagen Lotzmann, Vice President Sales KARL MAYER Technische Textilien.

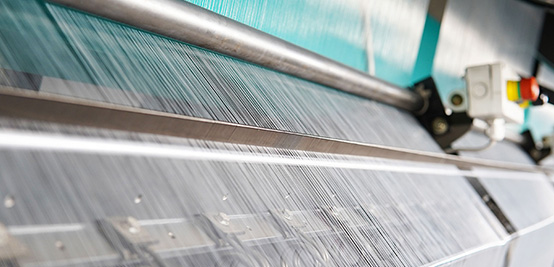

The winter sports equipment is the result of a subsidised project. The hemp tapes for this were supplied by FUSE GmbH and processed into non-crimp fabrics on the COP MAX 5 multiaxial warp knitting machine in the KARL MAYER Technical Textiles technical centre.

With the capacities in the company's own application technology centre and the expertise of its composite specialists, the company is able to support its customers in the implementation of projects and processing trials. The aim of the trade fair is to strengthen the company's image as a contact point for innovators also with unusual ideas. "Everyone is currently looking for new applications. We want to present ourselves as a competent development partner and special machine manufacturer in the composites sector," says Hagen Lotzmann. The sales professional and his team will also be presenting an innovation from the multiaxial machine sector for the production of composites made of glass rovings.

The STOLL Business Unit will be focussing on thermoplastic materials. Several knit to shape parts with a visually appealing textile outer surface and a hardened inner surface will be on display. The double-face products can be made from different types of yarn and do not need to be back-moulded for use as side door panels or housing shells, for example. In addition, the ready-to-use design saves on waste and yarn material.

The KARL MAYER Group is looking forward to its guests, numerous discussions and many new ideas.