#Composites

DORNIER's focal points at K 2022: Longer line service life and recycling management

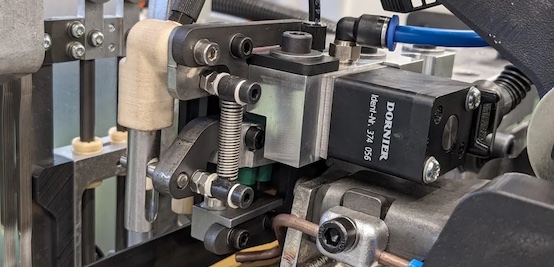

The pandemic caused the worldwide demand for hygiene articles and packaging film to rise sharply. This also spurred the sales of film stretching lines from Lindauer DORNIER. Because the lines from the technology leader are known for their longevity, one focus at the K will be the range of spare parts and services that was expanded during the Corona pandemic. This includes, for example, the all-inclusive maintenance and repair service for the patented DORNIER clips. About 2,800 of these clips ensure smooth film transport in the up to 150 meter long film stretching lines of the family-owned company. Film manufacturers have their clips maintained and cleaned by DORNIER specialists. In this way, over 60,000 clips are checked, overhauled and, if necessary, repaired every year. This not only saves the costs of a new purchase, but – sustainability being the keyword – also reduces the consumption of materials and resources and ultimately protects the environment.

Recycling and circular economy of film

The circular economy of film and its recycling will also be in focus at the K. "With its 10.6-metre wide BOPET (Biaxially-Oriented Polyester) film stretching line, DORNIER has the widest PET film production line on the market," says Bernhard Wandinger, Head of the Special Machinery Product Line at DORNIER. According to Wandinger, the line, the first type of which went into operation in 2019, not only produces more energy-efficiently, but due to its width also more than 20 % more film can be produced with almost the same energy input. Recycled PET is also processed on the line: "Waste, for example from PET bottles, can be recycled to 100% into new film on our BOPET line.“ A special in-house recycling system also feeds film waste directly back into production. "We are in constant exchange with customers about what we can do as a plant manufacturer to further optimize the recyclability of film," says Bernhard Wandinger, who expects new impetus here from the first K since the start of the Corona pandemic.

Virtuality meets quality

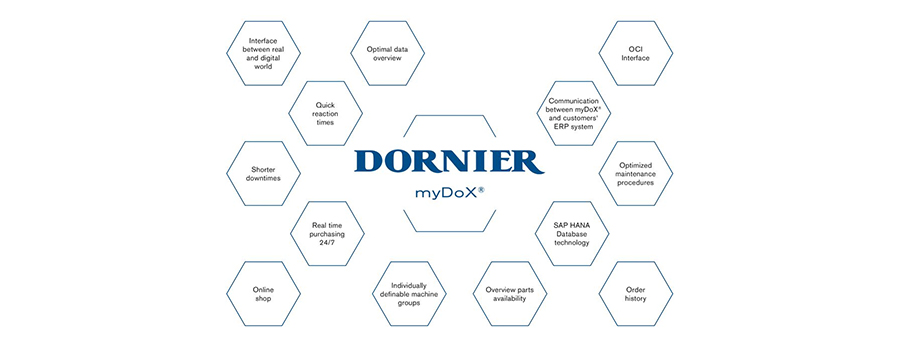

Another focus of the fair is DORNIER's digital product range, which was extended during the pandemic. In addition to further developments in the myDoX® customer portal, which is based on the latest database technology (powered by SAP HANA), new virtual offers for existing and new customers were implemented. For example, the digital contact options to the DORNIER sales and service teams have been further expanded. Virtual tours of the technology centres are also being used intensively by customers beyond the pandemic in order to see the latest machines, technologies and solutions for processing, for instance, plastic materials.

Customized systems for lightweight composite construction

New developments of the Composite Systems product line will also play a role at the K. In this line, DORNIER combines the know-how of its weaving machine and film stretching line divisions to manufacture machines for the production of high-quality fiber composite structures and components. "In view of the increasing demands for sustainability and energy efficiency, enquiries for tailor-made plants for composite lightweight construction are noticeably increasing," says Product Line Manager Dr. Josef Klingele. Whether in vehicles, aeroplanes or wind turbines – fibre-reinforced composites ensure greater lightness, economy and sustainability everywhere. According to Klingele, future-proof lightweight composite construction is not only oriented towards the material itself – the optimal interaction of material, process and application is also important. With its PROTOS® (Polymer and Roving to Sheet) and TRITOS® (Textile Roving into Three-dimensionally Oriented Structure) production systems, DORNIER will therefore present integral solutions for the economical production of high-quality and customized fiber composite structures at the K. "As a machine and plant manufacturer that develops customized solutions virtually on a daily basis, we traditionally have a close personal relationship with our customers," says Klingele. "That's why we're looking forward to meeting many of them in person at the anniversary edition after the K's corona-related break."

Visit us in Hall 3 | Booth A19.