#Associations

AATCC TM214: New approach to an old challenge

AATCC TM214 Test Method for Measuring Condensation on Textiles in a Humid Microclimate can be purchased now as a downloadable PDF and will be included in the 2024 AATCC Manual of International Test Methods and Procedures.

Order AATCC TM124

Test Method for Measuring Condensation on Textiles in a Humid Microclimate

https://members.aatcc.org/store/tm214/3776/

AATCC TM214 applies to clothing systems, tenting fabrics, and medical and technical temporary shelters. The condensation rate heavily depends on temperature and vapor pressure across a fabric system.

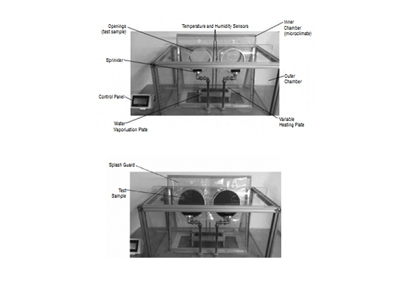

AATCC Research Committee RA63 Water Resistance Chair Kiarash Arangdad of Elevate Textiles shared that the new method is designed to measure the water condensation accumulation on the innermost (back) surface of waterproof fabrics in a humid microclimate. During the test, the outermost fabric (face) surface is subjected to dry and wet conditions (simulated precipitation). The condensation accumulation is determined by calculating the mass change of a filter paper attached to the inner chamber for a prescribed time.

Although several existing test methods measure the effectiveness of moisture transport mechanisms through fabric, this is the first method to measure condensation created by the microclimate of the textile product. TM214 is a valuable tool for the textile industry to assess the performance of fabrics in wet and dry conditions.

The test apparatus has an inner chamber (microenvironment) and an outer chamber (simulated precipitation). The test can be conducted inside an environmental chamber or under ambient conditions. This feature allows broad use across various textile systems for accurate representation of a company’s unique platform.

As businesses look for effective ways to drive sustainable practices within their value chains while addressing the challenges of changing climates across our global community, this test method is an important step forward in helping the textile industry better understand the role condensation plays on textile components. The insights gained by using this method will help organizations improve and develop new hydrophobic and water-repellent fabric systems.

Participate

All AATCC test methods are developed by industry experts. To be part of the process, join today! Committees, including RA63 on Water Resistance, are always looking for new ideas and new perspectives. If you’re already a committee member, be sure to log in to the new Communities platform to stay current on projects, discussions, and more.

Attend AATCC Research Committee Meetings

May 15-18

https://www.aatcc.org/aatcc-events/research/

The next round of meetings are May 15-18. There is no fee to attend and all are welcome. Share your thoughts on AATCC TM214 or suggest a new project. You can take part in person at the AATCC Technical Center or virtually from wherever you are.