#Yarn & Fiber

Teijin’s Tenax and PAN to earn ISCC PLUS certification for bio-based and circular raw materials

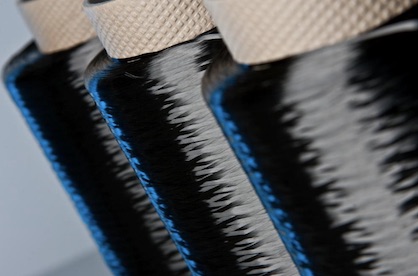

TenaxTM Carbon Fiber

The PAN precursor fiber is made from sustainable acrylonitrile (AN) using waste and residue from biomass-derived products or recycled raw materials, and produced by using the mass balance approach method. With this method, materials are verifiably tracked through complex value chains, for example, when biomass-derived raw materials are mixed with petroleum-derived raw materials to create products.

Because the sustainable AN has the same physical properties as petroleum-derived AN, PAN and TenaxTM Carbon Fiber based on this material deliver the same physical properties as equivalent fossil-based products. This similarity allows customers to easily replace TenaxTM Carbon Fiber with more-sustainable alternatives that can contribute to the reduction of greenhouse gas (GHG) emissions throughout the product life cycle.

Teijin expects to begin commercial production of PAN and TenaxTM using the mass balance approach method at the Mishima plant by the first half of 2024. Also, the company will pursue ISCC PLUS certification for its carbon fiber and related products produced in Europe, the United States and Asia to expand availability of its sustainable products. This initiative will advance the Teijin Group’s mission of providing innovative, people-centered solutions that improve the quality of life. Teijin will continue striving to mitigate the impact of its business activities on the environment to realize its long-term vision of supporting the society of the future.

Carbon fiber, a strong yet lightweight material that can help reduce energy consumption, is used in a wide range of applications including aerospace and industrial fields. Meanwhile, the need to reduce GHG emissions throughout supply chains in support of carbon neutrality is generating demands for products with a lower environmental impact. Under these circumstances, Teijin switched the fuel for in-house power generation equipment at manufacturing sites to natural gas and adopted lifecycle assessment (LCA) to calculate the environmental footprint of its carbon fiber and intermediate materials.

*The Teijin Limited Mishima Plant shall commit and declare compliance with the ISCC PLUS requirements in accordance with the latest regulations of the ISCC.