#Yarn & Fiber

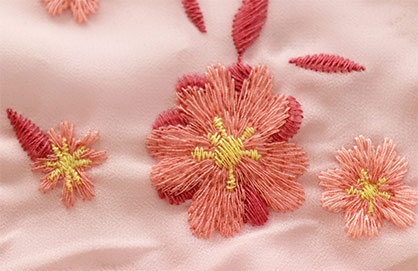

Ebru Nakis’s colorful products come to life with Durak Tekstil threads

Embroidery, adding value to textile products, is the most important decoration method of fashion today as in the past. Embroidery continues to be indispensable for fabric surfaces with its appeal and added value even though different colors, patterns, and structures emerge depending on the trends. Embroidery production directly affects product quality both visually and tactilely and is carried out on industrial machines with the special threads required for this. Durak Tekstil, one of the important manufacturers of industrial sewing and embroidery threads, stands out among the most important partners of embroidery manufacturers with its rich product portfolio, fast shipping, and advanced service. Ebru Nakis, one of Durak Tekstil’s customers, has been using Durak Tekstil threads in its embroidery applications since the day it was founded.

Ebru Nakis was established in 1990 in Istanbul and has achieved continuous growth in its journey that started with contract embroidery manufacturing. The company that was in production with 10 machines in 1995, provides solutions especially to export-oriented companies with over 200 machines and approximately 950 staff today. The company owns an embroidery facility in Adapazari and a fabric knitting unit in Istanbul Haramidere in addition to its Istanbul Mahmutbey facility, and has a very competitive power with its expertise in embroidery. Ebru Nak?? has a rich product and service portfolio, working with clothing and fashion giants such as Inditex Group, Levi’s, Esprit, H&M, Hugo Boss, M&S, and Taha Group. The company offers its customers products such as; embroidery, tufting patch, emblem, canvas, sequin, corduroy-lase, bead embroidery, chain embroidery, strainer, laser cutting, perforated work, and stone bonding.

Ebru Nakis company founder and owner Hasan Öner defines embroidery as the most beautiful accessory product of textile and says that they are one of the biggest embroidery companies not only in Türkiye but also in Europe. Öner disclosed; “We realize 4% of all embroidery production of Türkiye with our most advanced embroidery technologies and qualified personnel. In addition to international brands, important manufacturers in the clothing industry that produce for these brands also work with us. They prefer us because of our quality and our power to offer the desired pieces at the desired time. We have the power to produce the samples in 6 hours after the order is placed, and carry out the actual production in 12 hours after the approval.”

Öner explained that they produce embroidery mainly for women’s/men’s clothing in addition to baby/children's clothing and home textile products. He stated that they both work with strong brands in Türkiye and supply embroidered pieces to textile companies aiming for export.

“We have been with Durak Tekstil since the beginning”

Hasan Öner noted that thread quality and color variety are very important in embroidery production, and expressed the following; “The thread must be in the desired volume, workability and colors both when being embroidered and in the finished embroidery design. Thread breaks will interrupt embroidery production, as well as defects in the thread body and color differences may cause problems in the pattern. We have been using embroidery threads of Durak Tekstil since the first day we set out in 1990 in order not to experience all these problems.”

Öner, pointing out that the supply of embroidery threads has increased regularly due to the increase in their production capacity, explained that they use different embroidery threads for different applications. He said; “We were producing embroidery with viscose threads when we entered the sector, then we switched to polyester threads. Durak Tekstil has become a reliable solution partner in this regard. We prefer Polysoft 40 as upper embroidery thread and Durafix 180 and 200 as sequin thread. We safely use Polystrong PP 120 threads as the matte upper embroidery thread while we use Mekik 150 as the bobbin thread. In short, Durak Tekstil threads enable us value-added production in a wide range of uses.”

“The color portfolio meets our demands and our production continues uninterrupted”

Hasan Öner stated that in addition to the high quality of embroidery threads, it is important for them to have the desired color standards and consistency. He disclosed; “It is important for us to be able to produce embroidery in the color and texture demanded by our customers. For this, the thread color and volume must remain the same throughout the lot as determined. Having color differences in the same type of thread spoils the appearance of embroidery and may cause problems for the customer. We do not run into such a problem with Durak Tekstil embroidery threads, color differences are almost non-existent. Durak Tekstil empowers us in embroidery production with a very rich thread and color portfolio, so we can produce the models our customers want quickly and without errors.”

Öner explained that a good thread shows the same performance in all machines and remarked that Durak Tekstil threads provide the same successful results in different machines and there is no need for fine/sensitive adjustments. Saying “these embroidery threads work successfully in all machines,” Öner pointed to the fact that the productivity of the staff increased as they did not have to make fine adjustments on the machine thanks to the thread.

“Certificates that guarantee quality make our work easier”

Hasan Öner, explaining that Durak Tekstil also provides the necessary certificates for its products, continued his words as follows; “Various product-related certificates, especially on quality, are requested since we serve exporter customers. Durak Tekstil presents us certificates on quality and strength, as well as certificates showing that their embroidery threads are harmless to the environment and human health. OEKO-TEX certificate is one of the fundamental certificates for our customers and Durak Tekstil provides us with this certificate for their embroidery threads, for example. These prove to be harmless for human and environmental health and also give very successful results in criteria such as color and brightness fastness, washing fastness, and perspiration fastness. The embroidery we produce can meet the standards determined throughout its use from the first day in this way. This means customer satisfaction for us.”

Öner pointed out that Durak Tekstil provides very fast service regardless of whether the order quantity is low or high, stating that they carry out production without having to keep high stocks thanks to this support. He noted that there is a relationship and communication between the two companies based on trust and added that they aim to continue working with Durak Tekstil in the coming period.