#Textiles & Apparel / Garment

YKK’s net-zero commitment drives new business strategy for decarbonization and circular economy

ONE YKK vision anchors new medium-term plan in 2025 integrated report

“Sustainability is not a slogan—it’s a strategy,” said Koichi Matsushima, President, YKK Corporation. “With our Net-Zero commitment and the ONE YKK vision, we are taking bold steps to transform our business, empower our people, and lead the way toward a circular economy.”

Driving toward Net-Zero emissions — Climate change

YKK’s goal to achieve net-zero GHG emissions by FY2050 has been officially validated under the SBTi Net-Zero Standard. The company is targeting a 90% reduction in Scope 1, 2, and 3 emissions by FY2050 compared to FY2018 levels, covering both its operations and supply chain. YKK’s climate leadership has been recognized with a second consecutive CDP “A List” rating and its third designation as a Supplier Engagement Leader. Key achievements include:

• Cut Scope 1 and 2 emissions by 57% from FY2018 levels, reducing total emissions to 234,679t

• Lowered Scope 3 emissions by 14.4%, reducing total emissions to 747,276t across the supply chain

• Boosted renewable energy usage to 61.2% of total power consumption

• Transitioned 45 global sites to 100% renewable energy, including full conversion in the China region

• Expanded solar energy capacity, adding 7 new facilities for a total of 34 operational sites

• Initiated equipment upgrades to phase out coal-fired boilers and reduce fossil fuel dependency

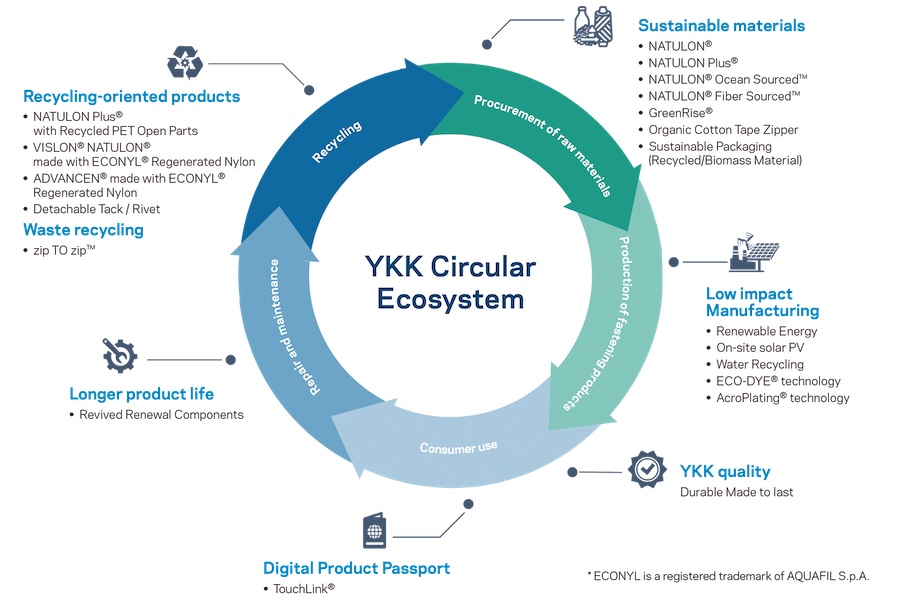

Innovating for circularity and resource efficiency — Material resources

YKK is accelerating circularity through innovative product design and material reuse. Key achievements include:

• Increased use of sustainable materials to 48%, marking a 10-point year-on-year improvement

• Transitioned 20% of packaging materials to sustainable alternatives

• Raised waste recycling rate to 93.9%, up 2 points from the previous year

• Prioritized sourcing from suppliers certified with “The Copper Mark”, and actively encouraged others to pursue certification

• Introduced NATULON Plus® with Recycled PET Open Parts to support garment-to-garment recycling

• Launched Revived Renewal Components, extending garment lifecycles through repairable components

• Conducted in-house recycling trials at the Kurobe Plant for copper and zinc alloys used in zippers

• Promoted environmental stewardship through tree-planting and clean-up initiatives

Strengthening water stewardship — Water resources

YKK continues to reduce water consumption and manage water quality across its operations. Key achievements include:

• Reduced total water intake by 7.5% compared to FY2018, reaching 10.638 million tons

• Monitored and addressed water intensity, which increased by 3.2% year-on-year

• Installed new production and recycling facilities at 15 sites to lower water consumption

• Managed wastewater quality in accordance with ZDHC Wastewater Guidelines

• Implemented water risk mitigation activities to safeguard local ecosystems and communities

Ensuring chemical safety and supply chain compliance — Chemical management

YKK is committed to responsible chemical management throughout its supply chain. Key achievements include:

• Engaged 1,793 suppliers by sharing the updated YKK Restricted Substances List (RSL 2024) and conducting compliance surveys

• Updated the YKK RSL for 2025, reflecting evolving social expectations and customer requirements

• Monitored chemical safety compliance through testing with OEKO-TEX® STANDARD 100 (44 companies) and AFIRM RSL (39 companies)

• Deployed ZDHC MRSL compliance assessments using InCheck reports across 17 production sites

• Identified and replaced non-compliant materials in the YKK RSL (2024 version), driving innovation in sustainable materials and manufacturing processes

• Established a cross-functional task force to address YKK RSL non-compliance across departments

• Initiated regular inspections at chemical management sites to prevent soil contamination and ensure environmental safety

Championing human rights and fair labor practices — Respect people

YKK continues to uphold ethical labor standards and human rights across its global operations. Key achievements include:

• Implemented weekly monitoring systems to manage working hours at all manufacturing sites, ensuring fair labor conditions

• Strengthened human rights due diligence by conducting self-assessments at 51 locations and third-party audits at 24 locations, based on the YKK Global Criteria of Compliance (YGCC)

YKK remains committed to engaging stakeholders and driving sustainability across its global operations. Detailed progress and performance metrics are available in the 2025 Integrated Report, with additional ESG and financial data in the accompanying Data Book. YKK invites stakeholders, partners, and customers to explore the full report and collaborate in shaping a more sustainable and circular future.