#Textiles & Apparel / Garment

New Gore-Tex products with recycled bionic textile

Gore has collaborated with the Bionic team to support their mission of reducing ocean plastic through community engagement by investing in their plastic recovery and sorting facility in Cóbano, Costa Rica. Through this effort, the operation collects plastic waste so it does not end up in the ocean. Sorted plastic waste is then turned into materials used in the textile component of these new GORE-TEX Laminates.

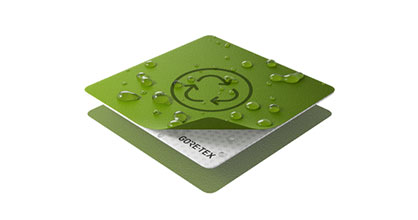

Introducing new GORE-TEX Laminates made with recycled BIONIC textile

Turning garbage into good - partnering with remote communities to repurpose coastal plastic waste

The two new laminates with recycled BIONIC textile mark another milestone in Gore Fabrics Division’s ongoing sustainability journey. The development of the laminates is also reflective of the Division’s strong commitment to responsible performance – a commitment to the increasing urgency for meaningful action and sustainable solutions within the global apparel industry that could help change the trajectory of our planet and the people who call it home.

“The new GORE-TEX Laminates with recycled BIONIC textile are a testament to how we can use meaningful scientific innovation to seek bold solutions for some of the most complex problems facing our industry,” said Achim Loeffler, Consumer Fabrics Business Leader, W. L. Gore & Associates. “We believe in the power of going further, together by working with like-minded brands; our collaboration with Bionic and Patagonia will enable us to turn garbage into good.”

Patagonia will introduce the first products featuring new GORE-TEX Laminates with recycled BIONIC textile in the Autumn/Winter ‘23 season. In future seasons, additional GORE-TEX Brand customers will introduce products featuring the new laminates, all of which are:

- constructed with Gore’s new ePE membrane and 100% recycled BIONIC polyester textile – made from 50% plastic waste collected from Bionic’s operations in coastal communities and 50% from other municipal collection

- certified according to Global Recycled Standard (GRS)

- durably waterproof, windproof and breathable and covered by the brand’s renowned GUARANTEED TO KEEP YOU DRY Promise

“Great partnerships are built on shared vision and passion, complementary expertise and the collaborative skills and discipline to see things through. This innovative project between Patagonia, Gore, and Bionic represents that shared vision and what the future can, and should, look like for high performance outdoor protection – same waterproof performance, no forever chemistries, and radically recycled NorthStar material inputs,” said Mark Little, Global Product Director, Men’s Life Outdoors for Patagonia.

Gore provided investment, material science and supply chain knowledge to Bionic, helping to create a robust, scalable supply chain, as well as local recycling infrastructure in the Costa Rican communities. In addition, Gore and Bionic use the phrase STRONGER THREAD. GREATER GOOD. to represent the collective action that connects brands and consumers with their community driven environmental operation in Costa Rica.

Together with the Cóbano community, Gore and Bionic have collaborated to set up:

- local waste management system to repurpose plastic waste

- recycling stations along roads and beaches

- organized community beach cleanup events and community outreach

- centralized sorting, bailing and flaking facility and collection routes for local businesses, schools and other institutions

“This launch is the culmination of years of close collaboration with Gore, the development of novel processing techniques, and the creation of an entirely new and traceable supply chain. Raising the profile of BIONIC textiles to the standards of the GORE-TEX Brand has been the best kind of challenge and resulted in a truly special material that has found a perfect home at Patagonia, with its long history of high-performance innovation and stewardship,” said Tim Coombs, Bionic co-founder.

Gore first announced their relationship with Bionic in December 2020.