#Textile chemistry

How to defossilise the chemical industry: RCI’s new policy proposals for a renewable carbon future

The European chemical industry, a cornerstone of manufacturing with significant economic impact and a key enabler for many other industries, is at a crossroads. The sector is facing an acute crisis due to global competition, rising energy costs and regulatory burdens. Once a leader in patents and production, Europe now trails behind China and the US, reflecting signs of declining competitiveness. The sector’s heavy reliance on fossil fuels for raw materials (over 90%) exacerbates its challenges, creating dependencies and limiting control over its carbon footprint at a time when Europe is grappling with the need for a green transition to ensure long-term prosperity and competitiveness. As a result, there are clear signs of ongoing deindustrialisation in the EU chemical industry.

Amidst these challenges lies an opportunity: Defossilising Europe’s chemical sector by transitioning to renewable carbon sources such as biomass, carbon capture and utilisation (CCU) and recycling. This shift is not merely an environmental necessity, but a strategic move to enhance Europe’s industrial competitiveness and resilience in the global marketplace. However, progress is hampered by regulatory barriers, the slow expansion of renewable energy, insufficient demand for sustainable products and limited uptake of new technologies.

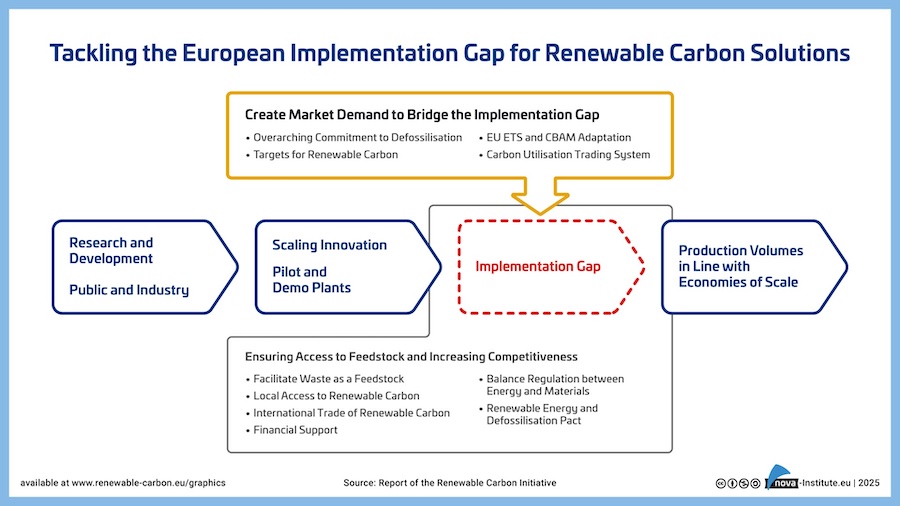

To address these barriers, the Renewable Carbon Initiative (RCI) has released a comprehensive report outlining ten policy proposals designed to accelerate the transition to renewable carbon in feedstocks and materials. Developed in collaboration with experts from nova-Institute and RCI members, these proposals aim to bridge the gap between innovation and large-scale implementation.

A vision for defossilisation: Driving change through targeted policies

The defossilisation of Europe’s chemical industry requires not only a clear commitment to defossilisation but also an actionable policy framework that supports, guides and incentivises the transition to renewable carbon. At the heart of this vision is an overarching commitment to defossilisation – a high-level agreement that establishes the foundation on which all future European policies can build upon. To create concrete market demand for sustainable products from renewable carbon, mandatory targets for the use of renewable carbon in chemicals and materials should be implemented. This can either be achieved by novel regulation or adaptation of existing regulations such as the Packaging and Packaging Waste Regulation (PPWR), the End-of-Life of Vehicles Regulation (ELVR) or the Ecodesign for Sustainable Products Regulation (ESPR) – and an adaptation of the EU Emission Trading System (ETS) or an alternative European Carbon Utilisation Trading System (CUTS).

To make the transition to renewable carbon a reality, EU policy further needs to enable sustainable access to renewable carbon feedstocks while ensuring competitiveness at both global and sectoral levels. To achieve this, RCI’s policy proposals include concrete suggestions to facilitate access to more waste as a feedstock, secure local access to biomass from agriculture, forestry and carbon capture, lead the way on international trade of renewable carbon feedstocks, balance regulation between energy and material uses to maximise synergies and ramp up availability of affordable renewable energy e.g. by favourable conditions for alignment with defossilisation targets.

A new report by the Renewable Carbon Initiative outlines 10 concrete policy proposals to facilitate the transition of Europe’s chemical industry to renewable carbon. These proposals are aimed to support the target of a clean, but competitive chemical industry in Europe with increased resilience and lower fossil dependence. © nova-Institute

Addressing the implementation gap to unleash innovation

The transition to renewable carbon is not just about environmental sustainability; it is about securing Europe’s industrial future and maintaining its global competitiveness in a rapidly changing world. By pioneering renewable carbon technologies, the EU can unlock economic benefits and unleash its innovation potential while advancing climate neutrality ambitions.

Addressing defossilisation and supporting the transition to renewable carbon will provide a comprehensive and reliable framework for the transformation of the chemicals and materials sector – in particular addressing the implementation gap from innovation to scaled product.

As highlighted by the EU Competitiveness Compass: “To shift the economy towards clean production and circularity, the EU needs to develop lead markets and policies to reward early movers.” The RCI’s policy proposals are in line with this vision by addressing key challenges and providing actionable solutions.