#Textile chemistry

New data shows INSQIN® reduces the carbon footprint of textile coating by half

The assessment showed that, from the cradle to material factory gate, the Global Warming Potential for 1,000 square meters of waterborne PU synthetic is 45 percent less than that of solvent-based PU synthetic(1). An independent third party was engaged to conduct a critical review of the LCA study and results in accordance with International Organization for Standardization (ISO) standards 14040:2006 and ISO 14044:2006.

Nick Smith, Covestro’s Global Head of Textile Coatings, says: “The LCA provides an extra layer of assurance in the environmental performance of INSQIN®. It shows brands that this technology can help them reach their sustainability targets. Achievements in carbon footprint reduction will be important to not only fashion and sportswear brands, but also the automotive and furniture industries.”

The LCA delivers high-quality data on the environmental benefits of waterborne PU. In addition, the technology offers health and safety benefits, altogether enabling customers to make increasingly informed decisions on PU material sourcing.

The study compared a comprehensive range of parameters to assess the environmental performance of waterborne PU from the extraction of raw materials to coated fabric production, versus that of the conventional technology, which involves the use of the solvent dimethylformamide (DMF).

Reducing carbon footprint and acidification

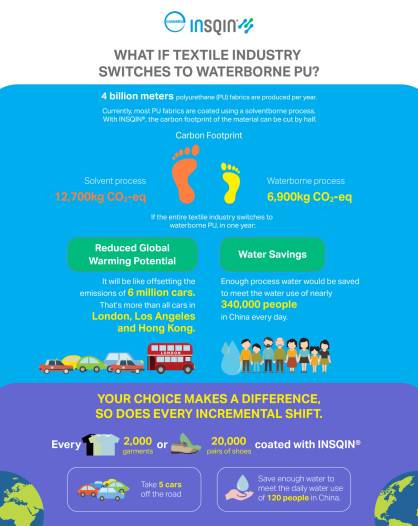

According to the results of the LCA, 1,000 square meters of PU synthetic made with INSQIN® has a Global Warming Potential of 6,900 kilogrammes CO2-eq, compared to 12,700 kilogrammes CO2-eq in the case of solvent-based PU leather.

The impact of this reduction is so significant that if the entire textile industry switched to using Covestro’s waterborne PU technology, the reduction of greenhouse gas emissions would be equivalent to taking every car off the road in Beijing, or in London, Hong Kong and Los Angeles combined.

While INSQIN® itself has a significantly lower carbon footprint than solventborne equivalents, the detailed study revealed that 85 percent of the reduction in Global Warming Potential is due to the lower energy consumption of the dry textile coating process that is enabled by the waterborne PU, and that replaces conventional wet processing. In other words, the real benefit of the technology lies in the process changes it makes possible.

Using INSQIN® to coat textiles with PU also has the potential to reduce acidification in our waters and soil by 20 percent, compared to conventional technology.

Reducing water consumption

According to Covestro’s previous internal study, the production of PU synthetics with INSQIN® uses 95 percent less process water than with conventional PU. The water savings achieved can have significant social impact on water-scarce manufacturing countries. If the entire textile industry switched to INSQIN®, enough water would be saved everyday to meet the daily water use of nearly 340,000 people in China.

This work demonstrates how innovation in chemicals can bring far-reaching benefits by enabling change in process technologies to bring about significant progress in overall innovation in the textiles industry.

Dr. Lydia Simon, Global Sustainability Manager for Coatings, Adhesives & Specialties at Covestro, says: “Life cycle thinking is crucial if we are to overcome key challenges such as climate change. Life cycle studies help to quantify the potential of technologies to reduce environmental impacts and thus contribute to more sustainable solutions.”

(1) Global warming potential,commonly known as carbon footprint, refers to the capacity to influence changes in the global average surface-air temperature and subsequent change in various climate parameters and their effects, such as storm frequency and intensity, rainfall intensity and frequency of flooding.