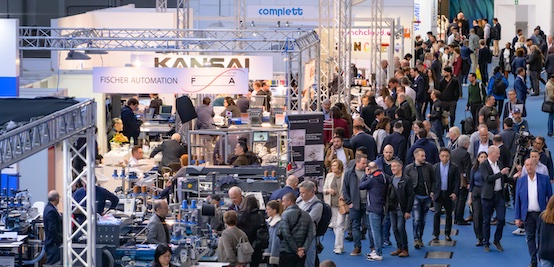

#Texprocess 2024

PFAFF INDUSTRIAL & KSL will showcase a wide range of innovations at Texprocess

In the GARMENT section, they will be showcasing quality-enhancing solutions for the production of high-quality jackets (PFAFF 3827, PFAFF 3822, PFAFF 3704). The first-ever presentation of the PFAFF SSD, a process reliable skip stitch detection system for double chainstitch machines, will take place at the trade fair. Its applications include closing or topstitching seams in trouser or airbag productions, where a complex, optical quality inspection of the seam (stitch pattern 401) is necessary. The world's best automatic pocket setter, the PFAFF 3688, will also be presented in Frankfurt with an innovative fullness function and automatic bartack reinforcement, enabling the high-quality processing of delicate stretch fabrics or heavily used pockets.

In the medium-heavy range, they will showcase various solutions for seams in both visible and non-visible areas. The flatbed machine POWERLINE 2545 and the electronic post-bed machine PFAFF 1591 will make their debut in Frankfurt with a new, robust, and reliable short thread trimmer. These machines come equipped with a new device for a neat seam start and are tailored for double-needle decorative seams on large, bulky, and voluminous parts (such as leather, technical applications, and dashboards). Additionally, PFAFF INDUSTRIAL will present the long-arm version of the PFAFF 5696 with a narrow post of 25 mm, ensuring high seam quality and stitch reliability even with thick threads, thanks to mirrored hooks and electronically controlled thread tension that adjusts to material thickness.

CNC technology, a core competence of PFAFF INDUSTRIAL and KSL, will be showcased with sewing ranges from 500 x 400 to 1,500 x 1,000 mm. A highlight of the exhibition will be the KL 311 featuring a 360° rotating sewing head and the innovative AI-based Online VISION SYSTEM for guided sewing. This system is utilized for topstitching decorative seam designs on fully and partially perforated leather and fabric, ensuring control and optimization of seam patterns between perforations, minimizing waste and operator influence while achieving maximum quality results.

With the Crosswelder PFAFF 8420 (hot-wedge version), PFAFF INDUSTRIAL is unveiling an absolute world first, enabling welding in a new size dimension with two synchronized moving heads. Applications include tarpaulins, sun protection, advertising banners, and many other technical textiles, with a modular concept allowing for the addition of hot-air technology.

The PFAFF 8303ix, an evolution of the market performer PFAFF 8303i, features innovations such as a new tape cutting and guiding concept, enabling infinitely variable adjustment of tape widths from 8 - 30 mm. Equipped with a new type of 3D axis nozzle swiveling, the PFAFF 8333 tape welding machine allows for continuous seam sealing with preset welding programs and an ECO-MODE to reduce energy consumption and CO2 footprint.

Finally, they will present two PFAFF 8311 ultrasonic welding machines (1x standard, 1x long arm with Cut&Seal) and a PFAFF 8320 standard hot-wedge machine. Visitors are eagerly awaited at their 550 sqm booth in Frankfurt!