#Techtextil 2022

Mastering the heat in synthetic filament production

Retech presents its latest innovations at Techtextil

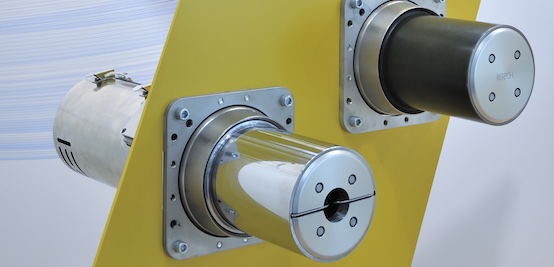

Identifying a strong demand for technical yarns with maximum strength, Retech addressed this with the newly-launched godet roll, with an ideal length of 420 mm to process eight or twelve threads at a time. Its extended diameter of 250 mm allows a significantly increased speed with the same dwell time. Additionally, the higher motor torque guarantees the very best results in yarn tenacity. Further technical parameters are as remarkable: speed can be ramped up to 6500 m/min and the temperature reaches 250°C with an excellent temperature profile of +/- 1.5 °C.

High-temperature godet rolls are invented for high-performance fibres. Some unique yarn characteristics are made possible by impressive temperatures. High-performance fibres require temperature at extremely high levels, since fibres such as para-aramids have high glass transition temperatures nearing 370 °C. Retech high-temperature godet rolls have a heating power of up to 400 °C. They also offer outstanding performance in terms of precision within 0.5°C – guaranteed by the established Retech temperature controller – and repeat accuracy from 1 to 100 godets.

Retech’s innovations for godet roll temperature management are precise, reliable, easy to handle, and durable. One of these innovations is the temperature transmitter which proves to operate in the harshest electromagnetic environment at highest precision. The system’s key part, the co-rotating sensor fork was recently revolutionized. Latest electronic and new materials compensate for disturbing influences which could tamper with the measuring signal.

Last but not least, the UTL monitoring device analyses the data and integrates it in the communication protocol for perfect data security. The UTL guides filament yarn producers toward Industry 4.0.