#Techtextil 2019

KARL MAYER was the meeting-point for the sector at Techtextil

KARL MAYER was exhibiting as an innovative driving force and business partner with a wide range of products at Techtextil, held 14. – 17. 05 .2019 in Frankfurt

The level of interest from Korea was also surprisingly high. Many of the Korean technologists also had a stand themselves at Techtextil, with the aim of strengthening their export business with Europe, and they were able the gather information about the latest innovations on KARL MAYER’s stand. A delegation of representatives from well-known federations and companies from the Chinese textile and nonwovens sector also visited KARL MAYER’s exhibition stand.

Exchanging ideas and information at the highest level

The conversations covered a wide range of issues. “Many players in the technical textiles sector are involved in niche segments; they supply quite specific products and came to us with very specific questions,” said Jochen Schmidt, the Managing Director of KARL MAYER Technische Textilien GmbH, after the fair. Stephan Fichtner from the Application Technology Department confirms this: “We had some in-depth, technical consultations on Wednesday and Thursday especially.”

As well as these technical exchanges, many informative conversations took place, mainly with newcomers to the sector, regarding the company KARL MAYER and the production capabilities of its machines. Many traditional textile producers are still in search of new business areas, and received some useful impulses from KARL MAYER. This textile machinery manufacturer is an expert in areas that include technical textiles, composites and nonwovens. As well as offering production technology, it also comes up with innovative textile product developments. Examples of the latest trend themes were on show during the fair. A team of experts was on hand to provide more detailed explanations and to answer any questions.

Added value through digital solutions

KARL MAYER was also exhibiting its digital brand, KM.ON, together with its various product offerings. Rapid reaction to customer needs and market demands is also becoming increasingly relevant in the technical textiles sector. KM.ON’s digital solutions help its customers to network their production and make it more intelligent.

This system generated a great deal of interest on the stand. “The huge demand and conversations with our enthusiastic customers have shown once again that we have scored a direct hit with KM.ON and our systems, and we can offer them real added value,” says Maximilian Kürig, the Managing Director of KM.ON GmbH. Most of the partners in this mutual exchange of ideas came from companies involved in textile production and finishing. The themes included networked, more efficient, lean production, new business models, Industry 4.0 and artificial intelligence.

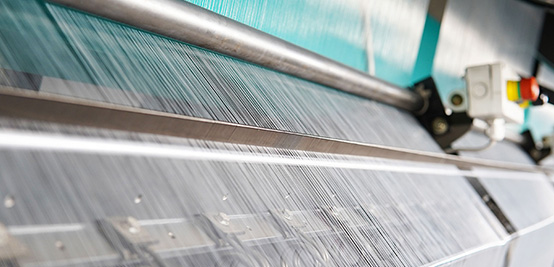

A successful in-house show was held as a parallel event

To coincide with Techtextil, KARL MAYER was also showing a model in its new RACOP-NW series at an in-house show at its nearby headquarters in Obertshausen. This raschel machine for web bonding, and examples of products, such as a thin textile incorporating electrically conductive yarns, generated many conversations regarding its market potential. The discussions focused on conductive and heatable textiles for the automotive sector, furniture upholstery, smart textiles and interior design applications.