#Sustainability

Fashion For Good launches fibre fragmentation project: Behind the break

The project brings together major fashion brands and manufacturers including adidas, Bestseller, C&A, Inditex, Kering, Levi Strauss & Co., Norrona, ON, Paradise Textiles, and Positive Materials, with Under Armour joining as a project partner. Testing will be conducted across three laboratories - Paradise Textiles, Under Armour, and IMPACT+ Network from Northumbria University - to analyse fi bre fragmentation in cotton knit, cotton woven, and polyester knit fabrics.

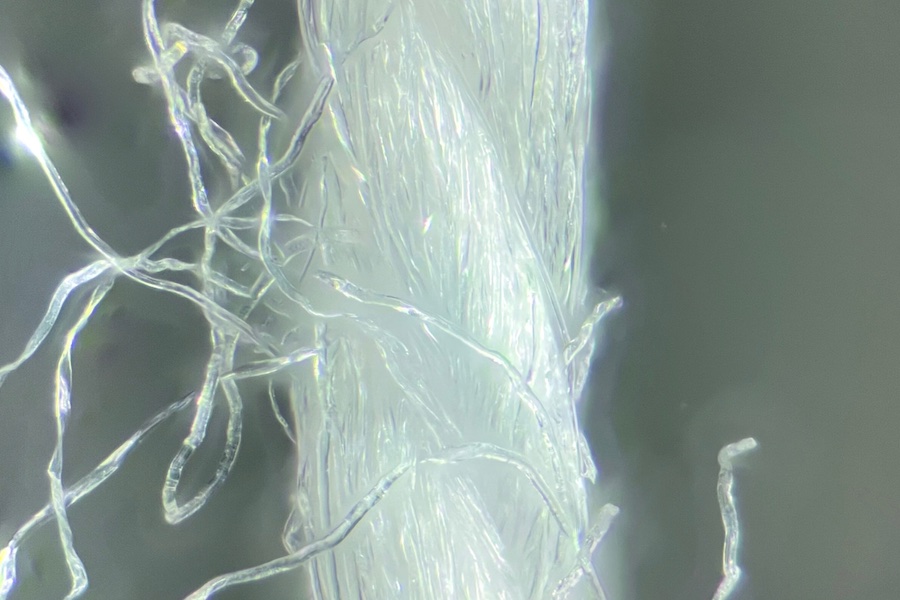

Fibre fragmentation is a signifi cant topic of concern across the industry, with studies highlighting the potential threat to ecosystems and human health. This underscores the urgent need for the development of effective strategies aimed at mitigating the negative impact of fi bre fragments.

In recent years, several domestic and industrial mitigation efforts have been developed to capture fi bre fragments before they enter air, water, and soil. However, the focus lies in reducing fi bre fragments from entering the environment downstream, rather than tackling the problem at the source.

It is pivotal for the industry to better understand the root causes and mechanisms of fi bre fragmentation. Therefore, under this initiative, Fashion for Good and The

Microfibre Consortium are launching:

? A new report, which aims to offer a snapshot of the issue of fi bre fragmentation through the lens of the textile and fashion industry, unpacking various aspects of this complex issue (defi nition, sources and pathways, root causes, analytical test methods, solution portfolio, biodegradation, toxicity and regulation).

? “Behind the Break: Exploring Fibre Fragmentation” project, identifying root causes of fi bre fragmentation within manufacturing processes (such as different dye methods) and how these infl uence fi bre fragmentation. It will focus on three different fabric types - cotton knit, cotton woven and polyester knit. The project includes various testing methods, leveraging the expertise of project partners Under Armour, Impact+ and Paradise Textiles. You can learn more about the testing details here.

"Fibre pollution is a challenge that the industry faces as a whole, so we are partnering with The Microfi bre Consortium to contribute to the foundation of data that will help us better understand the root causes of fi bre fragmentation. The focus on different testing methods will allow us to reduce uncertainty, take a common direction and set priorities for future research and initiatives within the industry”, said Katrin Ley, Managing Director at Fashion for Good.

Kelly Sheridan, CEO at The Microfibre Consortium, said: "Partnering with Fashion For Good has helped to unite the project partners behind the ongoing need for alignment on closing fi bre fragmentation knowledge gaps. With this rallied support, we can build on the existing state of knowledge and make great strides in addressing urgent topic challenges for a future of informed, science-led and integrated mitigation action.”

This initiative aims to identify the most effective approaches to tackling fi bre fragmentation at the source through the following insights:

? Enhancing Test Methods: Validate and refi ne testing techniques to ensure accuracy, reliability, and alignment with industry standards.

? Strengthening Data Correlation: Compare results across methods to identify variations, uncover discrepancies, and establish clearer data connections.

? Driving Improvements: Address limitations in current methods, expand databases, and support better design and supply chain practices.

? Supporting Stakeholders: Equip partners and industry players with practical strategies to reduce fragmentation through improved design and manufacturing.

? Informing Policy: Provide valuable insights into contamination and fi bre structures to shape effective regulations and policies.

To read the report and learn more about the project click here:

https://www.fashionforgood.com/case-study/behind-the-break/

Lucie Anne Martinol, Textile Innovation Lead at ON, said: "By conducting this study, we are taking a proactive approach to addressing microfi bre release. Our goal is to leverage data-driven insights to improve our processes, product design, and sourcing practices, thereby contributing to a less polluting industry. Collaboration across stakeholders is crucial to accelerating our progress toward a more sustainable future.”

And Lewis Shuler, Head of Innovation at Alpine Group/Paradise Textiles, said: "At Paradise Textiles, we recognise that the future of the fashion and textile industry hinges on our ability to address challenges like fi bre fragmentation head-on. By partnering with Fashion for Good and The Microfi bre Consortium, we're bringing collective insights together to validate theories on the root causes of fi bre fragmentation. Our objective is to identify processes and strategies that mitigate fi bre pollution through informed textile design and manufacturing processes. We're excited about continuing this critical work and pioneering innovative technologies that can reshape the industry for the better.”

“Positive Materials believes that reducing fi bre fragmentation requires innovation at every stage. Our partnership with Fashion for Good and The Microfi bre Consortium on Behind the Break is critical because we're not just aiming to reduce shedding; we're making sure our materials maintain the high standards our customers depend on. It’s about fi nding that balance where environmental responsibility drives innovation, not compromises it”, stated Elsa Parente, Co-CEO & CTO of Positive Materials.