#Sustainability

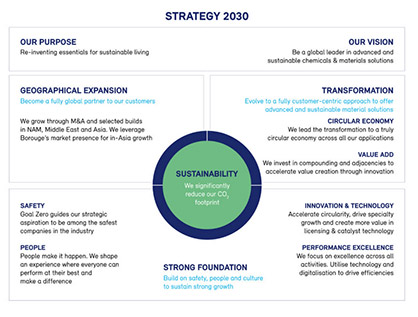

Borealis Strategy 2030: Re-inventing essentials for sustainable living

This foundation powers continued geographic expansion and the ongoing transformation towards the circular economy. The strategy stipulates new and more ambitious sustainability targets with regard to greenhouse gas (GHG) emissions reductions, energy consumption, and the circular economy. Underlying the Borealis Strategy 2030 is an evolved purpose, “Re-inventing Essentials for Sustainable Living,” whose intent and spirit is shared across the OMV Group.

- Strategy and purpose affirm Borealis Group vision to be a global leader in advanced and sustainable chemicals and material solutions

- Sustainability at the centre of all activities, supporting OMV Group’s ambition for a net zero business by 2050

- Strong foundation supports continued geographic expansion with enhanced focus on Middle East and Asia, North America

A strategic evolution centred on sustainability

The Borealis Strategy 2030 affirms that sustainability forms the core of all its current and future operations. The sustainability targets stipulated in the strategy cover GHG emissions, energy use, flaring, and circular economy products and solutions for Borealis Polyolefins and Hydrocarbons businesses.

Greenhouse gas (GHG) emissions:

Borealis aims to reduce its Scope 1 and Scope 2* emissions from 5.1 million tons (base year 2019) to less than 2 million tons by 2030. The emission reduction portfolio includes increased use of electricity from renewable sources throughout the decade and carbon capture projects which will come on stream in the second half of this decade. The reduction target also includes the announced divestment of the Borealis nitrogen business, which comprises fertilizers, technical nitrogen, and melamine.

Energy consumption:

In 2021, around 25% of the electricity Borealis used in its own operations was derived from renewable energy sources such as wind and solar power. By 2025, the share of renewables in the electricity mix will increase to 40%. By 2030, 100% of the electricity used in its Polyolefins and Hydrocarbons operations shall be of renewable origin.

Circular economy products and solutions:

Around 100 kilotons of products currently manufactured by Borealis in Europe are circular. These include recycled and renewable polymers and chemicals as well as renewable hydrocarbons. By 2025, Borealis targets a six-fold increase in the share of circular products and solutions, or 600 kilotons. By 2030, the volume of circular products and solutions is set to reach 1.8 million tons globally, turning today’s plastic waste into a valuable resource to be reused. Moving from a linear towards a circular economy will also significantly reduce the Borealis Group’s Scope 3** emissions.

Borealis Strategy 2030 driven by expansion and transformation – and powered by people

Geographic expansion and the transformation towards circular and value add materials are key pillars of the Borealis Strategy 2030. Both will be made possible thanks to the strong foundation of Borealis values, corporate culture, spirit of innovation and technology, and its people.

The Borealis Group's aspiration to become a truly global player serving its customers around the world has already begun with its

in global growth projects, including Borouge 4 (UAE), Baystar (US) and Kallo (Belgium). The Strategy 2030 emphasises the importance of serving the rapidly growing Asian market and expanding the Borealis Group footprint in North America. Additional strategic partnerships as well as mergers and acquisitions are planned. Organic growth opportunities in the form of newly established operational facilities are also under consideration.

As an industry pioneer in the transformation of the plastics economy from a linear to a circular one, Borealis accelerates the development towards becoming a fully customer-centric producer of advanced, sustainable material solutions in all business areas, from energy and infrastructure to consumer products, healthcare to mobility, and from pipes and fittings to advanced polymer solutions. The Borealis commitment to Value Creation through Innovation will continue to drive progress in the circular sphere. Borealis will build on the success of the proprietary and transformative ™ technology, which gives polyolefin-based, post-consumer waste a new life; and ™, its portfolio of premium circular polyolefins based on renewable feedstocks.

The strong foundation of it all is the Borealis culture and values: above all, a dedication to safety and a commitment to putting its people first; the mind-set deeply rooted in innovation and technology which accelerates circularity, drives specialty growth, and creates more value in licensing and catalyst technology; and finally, the Borealis Group’s relentless focus on performance excellence.

“The Borealis Strategy 2030 is our roadmap to making life more sustainable for future generations. Our significantly expanding footprint in value-added and circular chemicals and material solutions is rooted in our dedication to innovation and customer focus,” says Borealis CEO Thomas Gangl. “Re-inventing essentials for sustainable living is our commitment to do our part to address global climate change and our guide for our own sustainable success in a carbon net-zero world.”

* Scope 1 are direct GHG emissions that occur at the source and are controlled by Borealis. Scope 2 are GHG emissions stemming from the generation of energy purchased by the company.

** Scope 3 are indirect GHG emissions that are a consequence of company activities but occur from sources outside or not controlled by the company.