#Sustainability

The ECO PASSPORT by OEKO-TEX® certification of textile chemicals

The ECO PASSPORT by OEKO-TEX® certification

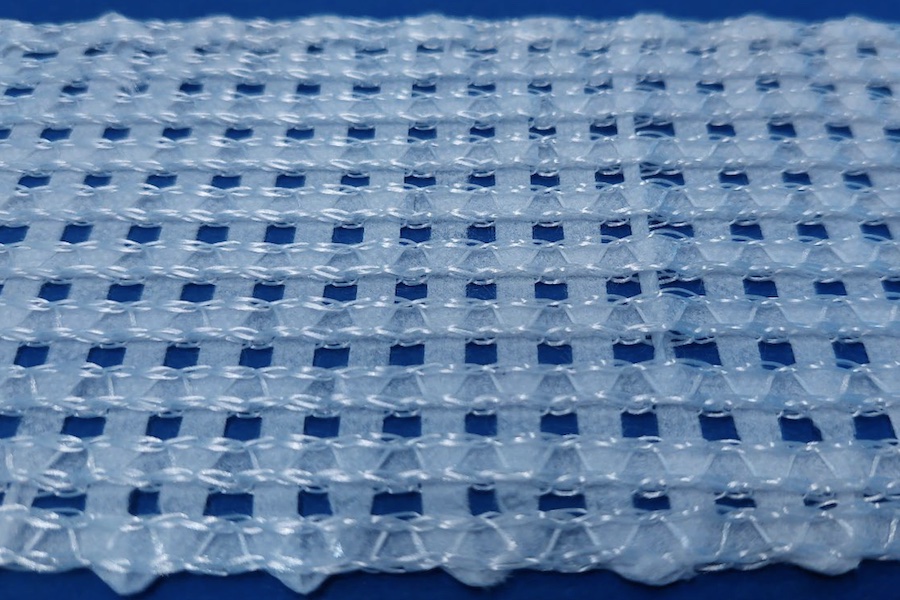

The ECO PASSPORT certification, conducted exclusively by Hohenstein in Germany, supplements the existing OEKO-TEX® certifications such as STANDARD 100 by OEKO-TEX®. For over 25 years, STANDARD 100 has been examining raw, intermediate and finished textile products for toxic substances and certifying textile products that pose no threat to health. The ECO PASSPORT certification follows a two-step process to analyse whether dyes, equipment, aids and other chemicals used in textile production can be classified as safe. Coning oils used to texture yarns may obtain ECO PASSPORT certification as production-specific aids.

The importance of the ECO PASSPORT by OEKO-TEX® certification

Two years on from the certification’s introduction, the OEKO-TEX® community has been able to certify more than 3000 products of over 400 customers worldwide. The certification makes it easier for companies manufacturing and selling textiles in accordance with STANDARD 100 by OEKO-TEX® to procure textile aids. It enables them to meet the market requirements for safe, non-toxic textiles, ensures that their textile-production staff are protected, help protecting the environment and the end consumer. For Total as an oil producer, the ECO PASSPORT certification means one extra step to adapt to the industry’s requirements and offer eco-friendly oils in order to set itself apart from its competitors.

ECO PASSPORT by OEKO-TEX® certification process

Hohenstein and the applicant work in close consultation throughout every stage of the certification. If possible, the applicant should have an existing quality-assurance system complying with ISO standards. The textile chemicals are tested in two to three stages at Hohenstein’s testing laboratory.

Stage I: Compliance screening

In the case of initial certifications, applicant queries are clarified before the application is lodged. Once the application has been checked, safety data sheets and the composition of the product to be certified are analysed and examinations conducted to determine whether any prohibited substances are used in production. If they are, the manufacturer is given an opportunity to adjust the composition accordingly. In the case of Total’s Lissolfix coning oils, no regulated substances are used meaning the composition did not need to be adjusted.

Stage II: Analytical verification

If there are no abnormalities during the initial test, a laboratory test is conducted comparing the components with the limit values regarding toxic substances in textile products. If, for example, the test specimen’s packaging has resulted in contaminants, a new test specimen may be sent to the laboratory for examination. The parameters of the examination vary according to the product. In the case of Total’s Lissolfix APZX 1350 / 1500 / 4800 coning oils, the test specimen was checked for parameters such as heavy metals, formaldehyde, phthalates, and chlorinated, organotin and volatile organic compounds.

Stage III: Sustainability check

The summer of 2018 sees a third stage added to the process. In the interests of sustainability, this stage will address environmental protection and OHS and involves on-site checks at the producer’s premises. It will initially only be conducted at the applicant’s request.

Validity of the ECO PASSPORT certification by OEKO-TEX®

The ECO PASSPORT by OEKO-TEX® certification is valid for one year. Extensions may be requested no earlier than three months prior to the certification’s expiry. This will involve re-assessment of the documents and a simplified laboratory test in order to ensure quality has remained consistent. The toxins’ limit values or the textile chemicals’ production conditions may also have changed in the meantime, necessitating another test to meet the requirements. If changes are made to the certified product during the certification’s validity period, the certificate holder is obliged to report the change and, if necessary, provide a new test specimen for testing. As an oil manufacturer for the industry, Total is one of the first providers of coning oils to have its Lissolfix APZX 1350 / 1500 / 4800 products certified, and is already planning additional ECO PASSPORT by OEKO-TEX® certifications.

Dipl. – Ing. (FH) Maren Kohl

Total Deutschland GmbH, Berlin

Dr. Jörg Schlatterer

Hohenstein Laboratories GmbH & Co. KG, Boennigheim