#Spinning

DTY Jet insert APe043 redefines low denier yarn processing

Record-small 0.65mm orifice launched during GTTES 2025

The Indian market drives demand for lightweight, premium fabrics using ultra-fine yarns, especially for activewear and luxury garments. The surge in synthetic fibre manufacturing positions Heberlein’s innovations as essential tools for meeting these needs. Visitors at GTTES 2025 receive first-hand information at Heberlein and are warmly invited to come and see the Swiss company at booth D17 in hall 3.

APe043 Jet insert improves productivity and profitability

The APe043 Jet insert minimizes yarn displacement, preventing undeveloped knots and ensuring smooth production for ultra-fine yarns down to 20 denier. This new technical development aligns with the increasing demand for high-quality fabrics in global markets and supports the rapid growth of polyamide filament production capacity. On top, the APe043 jet insert features energy-efficient technology resulting in a positive impact on the mill’s profit.

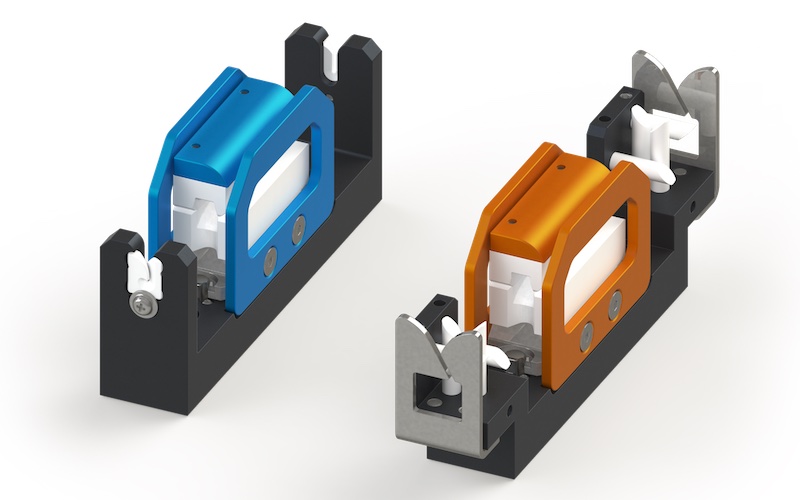

HemaJet-LB06 – the economic solution for ATY

Heberlein, known for the production of high-quality jets for air texturing, offers the complete solution from a single source. The brand new robust HemaJet-LB06 jet housing is compatible with all Heberlein jet core series (T, A, and S).

This compatibility makes it an ideal solution for various air texturing process requirements. The distance between the impact body and the jet core can be easily adjusted using various gauges, allowing for precise control and optimization of the texturing process.

Heberlein jet cores are the reliable solution for the ATY industry for decades. Suiting a wide range of requirements like compact and uniform yarns from 30dtex up to 3,000dtex or softer, textile yarns achieved through a higher overfeed potential. In a nutshell, Heberlein provides the ideal solution for every application. Customers can choose from the great jet core portfolio and whatever jet core fits the needs, it fits – guaranteed – the housing too.

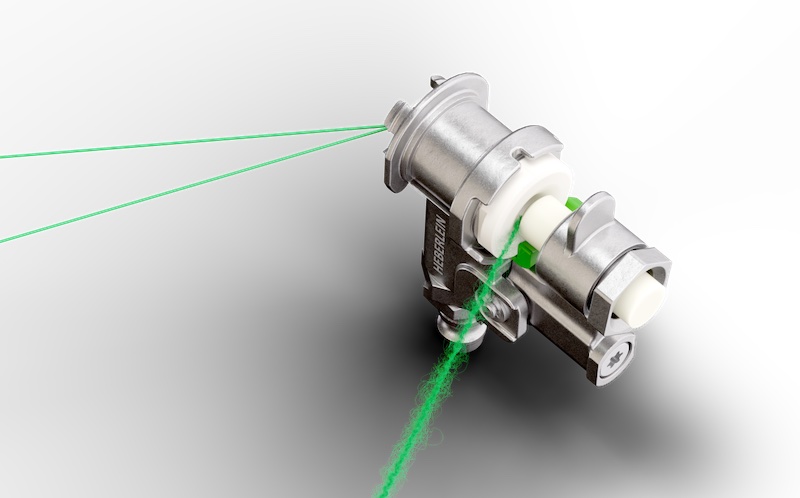

The new generation of spinning jet

Worldwide recognition receives the PolyJet-SP3 for spinning textile yarn. Producers of demanding technical yarns highly appreciate the PolyJet-TG-3-HP405A/WO70 (TopAir) achieving yarn with unmatched even and uniform interlacing density. Furthermore, this jet impresses customers with strong, reliable knots for high-tenacity yarns (HT and HMLS). Heberlein’s PolyJet-TG-3 achieves more than 12 knots per meter with 1100f98dtex and 1670f98dtex. Additionally, yarn parameters of tensile strength, elongation, and elasticity show smaller variations, for ultimate quality benefits, as well as improved unwinding behaviour of the bobbins.

A typical Heberlein benefit comes with the PolyJet series SP-3 and TG-3. The high-performance air interlacing jets for textile and technical yarns offer a unique quick-release system, so jet packs can be exchanged within seconds, with just a single 180-degree turn. They also feature a compact, space-saving design and a roll bar to protect the ceramic surfaces.