#Spinning

Oerlikon celebrates 20 years of e-save

Pioneers in sustainability

Rising energy prices, scarce resources, an ageing society, a shortage of skilled workers and lower profit margins in many industries prove Oerlikon's e-save mission right. For 20 years, the technology leader in manmade fiber production has been scoring points with significantly lower energy consump-tion compared to the market standard, the competition or its own predecessor models. Fiber and yarn manufacturers around the world appreciate this, as investments in new systems developed according to e-save criteria pay for themselves in a much shorter time. “Topics such as energy efficiency and the careful use of resources have become increasingly important for all our customers in recent years, not least due to stricter legal framework conditions,” says Georg Stausberg, CEO of the Oerlikon Polymer Processing Solutions Division. “Our e-save sustainability program and the associated tech-nology development over the last two decades has often given us the decisive advantage in numer-ous investment decisions on the customer side and thus the edge over the competition.”

Over 15 million tons of CO2 saved since the introduction of e-save

The Oerlikon Polymer Processing Solutions Division and its business units have been subject to DIN ISO certification for decades, they realize the CE marking and consistently implement the strict guide-lines for machine safety, especially in terms of protecting employees on the customer side. At the beginning of the millennium, however, this was no longer enough. The company and its managers wanted to voluntarily do even more with a view to the future. As a result, the e-save program was launched in 2004.

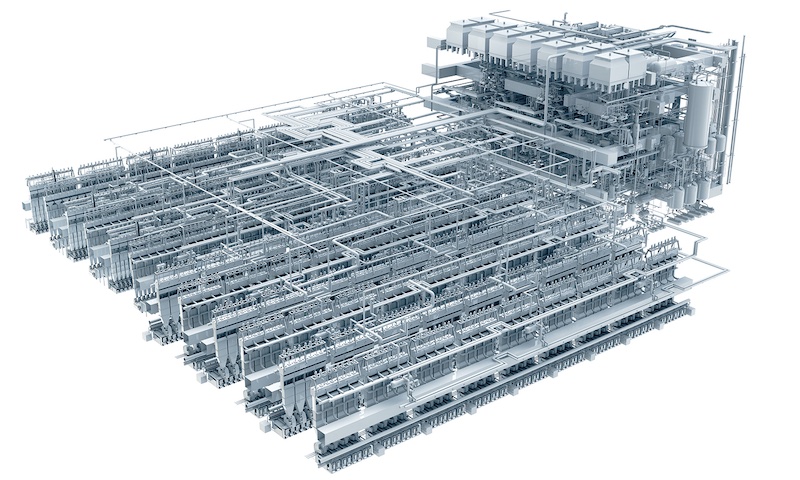

Since its introduction, hundreds of manmade fiber spinning mills worldwide have been equipped with technology solutions from Oerlikon Barmag, Oerlikon Neumag and Oerlikon Nonwoven. Around half of the currently installed production capacity for polyester, polypropylene and nylon is based on Oer-likon technologies. According to an estimate by the publication “TheFiberYear 2024”, this corresponds to almost 40 million tons of fibers and yarn annually. The corresponding CO2 balance is impressive: The e-save certified customer installations saved, cumulatively over the last 20 years, over 15 million tons of CO2. This is roughly equivalent to the emissions generated by around 15 million intercontinen-tal passenger flights per capita, or the amount that a forest with a surface area of 300 km² – roughly the size of Munich, Germany – can store.

Efficient heating and cooling creates energy-saving potential

What did the engineers focus on in the beginning? Heat is a crucial factor in polymer spinning sys-tems. Polyester melt is conveyed from the polycondensation plant to the spinning system at tempera-tures between 280 and 290 degrees Celsius. The hot filament coming out of the spinnerets is then cooled in the quenching unit before being drawn on hot godets, depending on the process.

“All of this has the potential to optimize energy consumption: WINGS POY (Winding Integrated Godet Solution) revolutionized the manmade fiber industry at ITMA 2007. The completely new winding con-cept already showed the potential to turn the entire industry upside down. All market participants were enthusiastic from day one,” says Jochen Adler, CTO of the Oerlikon Polymer Processing Solutions Division.

Chinese companies in particular already saw the technology that would make them global pioneers in the manmade fiber industry. Five years later, WINGS FDY conquered the market with even more e-save advantages, especially in the area of energy savings. The Oerlikon Barmag innovation achieved over 40 % lower energy consumption compared to the industry standard at the time. The return on investment (ROI) was and still is achieved very quickly. The best technology with the highest quality is therefore also worthwhile from an economic point of view. In addition to the Oerlikon Barmag core technology WINGS – today an indispensable part of a modern manmade fiber spinning mill – the company has set standards over the years with other components in the field of energy savings.

Benchmark market in the industry

The SP8x spinning head series, for example, is based on a reduced heat-radiating surface with signif-icantly improved insulation, resulting in more than 40 % less heat loss compared to its predecessor models. In concrete figures, this means energy savings of around 200,000 kWh per year for a system with 36 positions. The component therefore remains the benchmark in the industry.

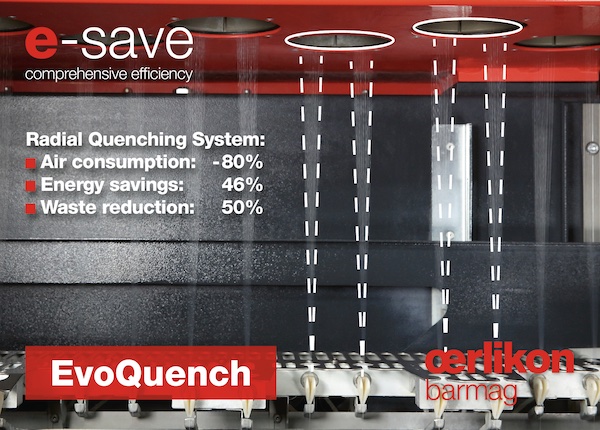

“The EvoQuench radial quenching system is a real cash cow thanks to its up to 80 % lower air condi-tioning requirement. In combination with the WINGS take-up system, up to 46 % energy and around 50 % waste can be saved compared to conventional technology, depending on the process”, so Adler. The latter is mainly due to the ergonomically unique concept of the take-up unit: The component is placed at eye level in record time; only one operator is required.

The sister company Oerlikon Neumag also contributed corresponding e-save components at an ex-ceedingly early stage. For example, the BCF tangle unit RoTac3 enables high energy savings through its targeted use of compressed air. Tangle knots are created with a pulsating rather than a continuous airflow, as is the case with conventional tangle processes. This means that compressed air is only ever used when a tangle knot is to be created. This significantly reduces the required volume flow or compressed air consumption – by up to 50 percent compared to conventional tangle units, depending on the yarn type. The component is naturally installed in Oerlikon Neumag's BCF S8 carpet yarn sys-tem, the most modern of its kind in the world. It makes a significant contribution to the energy-efficient production of carpet yarns. However, the system also convinces with impressive data thanks to the overall concept: Plant efficiency of 99%, higher throughputs of up to 15% and energy savings of up to 5% per kilogram of yarn.

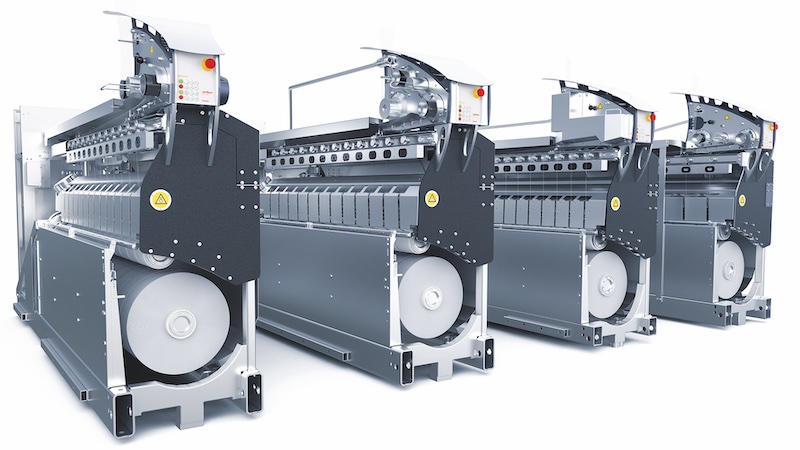

Less energy – more productivity

Compared to standard DTY machines, the Oerlikon Barmag eAFK Evo offers 30 % higher productivity with 20 % less energy consumption per kilogram of textured yarn. The significant increase in machine speed and the 50 % shorter texturing zone compared to a conventional machine ensure an exception-ally stable texturing process that enables maximum productivity and the lowest operating costs. The core component of the machine is the EvoCooler, whose sustainable cooling principle is based on the evaporation of water. This active cooling technology with direct contact to the yarn is independent of the ambient temperature and requires no additional energy. In addition, the low heat emission to the environment reduces the requirements for hall air conditioning. The collected coolant is recirculated and can therefore be recycled.

“Precisely coordinated process steps in the textile value chain also offer potential in terms of effi-ciency. One example is the WINGS POY HD and eAFK Big V high-titer concept, which is designed for a carpet and home textile product range that uses particularly soft and bulky polyester yarns with BCF-like properties. The aim here is to produce yarns with a maximum count of 1200den with over 1000 filaments. As standard, DTY yarns up to 1200den with up to 1152 filaments from four POY bob-bins 300den/288f are spun together on a DTY machine”, says Jochen Adler. However, the process has a fundamental disadvantage: half of the available winding positions on a texturing machine re-main unused. This is where the spinning concept with a WINGS POY HD take-up unit in combination with an automatic eAFK Big V multi-spindle texturing machine offers a highly efficient solution – cur-rently the only one on the market.

Water – a contested resource

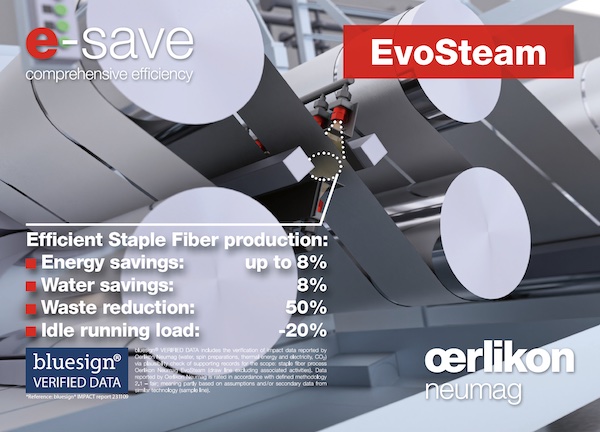

The most recent example of a sustainable e-save technology is the Oerlikon Neumag EvoSteam sta-ple fiber plant. Here, too, the relevant process steps in terms of sustainability were already taken into account during development. The innovative process does not require water baths. The result: water savings of up to 3.5 million liters per year, significantly lower consumption of drying energy and preparation, and ultimately a reduction in the CO2 footprint of up to 20 %. An optimized draw point release makes the EvoSteam staple fiber system up to 12% more efficient than previous concepts. Overall, the EvoSteam process reduces production waste by up to 50 % while at the same time saving up to 8 % energy.

Another example: the pollution of water by dyeing textiles is a much-discussed topic. With the help of the 3DD mixer technology once developed at Oerlikon Barmag, manmade fiber production offers the injection of color pigments as a masterbatch as early as the melt preparation stage – this really is an exceptionally clean alternative. A nice side effect: the dyeing of these spun-dyed yarns is much more uniform than bath dyeing of bobbins or textile surfaces, and the color fastness is unsurpassed. In addition, the spun material retains its color almost forever.

Last but not least – the entire textile industry is striving for solutions for a functioning and all-encompassing circular economy. Together with its joint venture partner BB Engineering, Oerlikon Bar-mag already has at least one solution for a zero waste manmade fiber spinning mill on offer. With the help of the VacuFil technology, production waste can be reprocessed to a high quality in the spinning mill so that the waste material can be directly reintroduced into the melt flow.

On top: bluesign® certification

A good 20 years after the introduction of the e-save label as a voluntary commitment by Oerlikon, the company is following suit and is also subjecting itself to the assessment of independent institutes such as the Swiss bluesign Technologies AG as part of the ESG criteria that have been legally binding for a few years now.

Last year, the Oerlikon Neumag EvoSteam staple fiber plant was awarded the bluesign® VERIFIED DATA label. The label includes the verification of impact data such as water, spinning preparations, thermal and electrical energy as well as the CO2 footprint by means of a plausibility check of the supporting records for the EvoSteam draw frame, the central element in the EvoSteam process. For yarn manufacturers, this means that all polyester staple fibers produced with the EvoSteam process will actively contribute to the bluesign® SYSTEM in the future.

“The trend towards greater sustainability is no longer just a trend, but a must for the industry and all market participants worldwide. With a view to the European Green Deal, we are creating even more transparency for our customers through external certifications such as bluesign® in addition to our own e-save label. In this way, we are intensively strengthening trust in all our products and services,” explains Georg Stausberg, who in addition to his role as Division CEO is also Chief Sustainability Officer (CSO) of the Swiss Oerlikon Group.