#Spinning

The perfect polo shirt with air-spinning

Polo shirts, the stylish combination of casual and business, are celebrating a comeback, especially in menswear. For a summery look, single-jersey models are favoured, while for universal year-round use, customers prefer the classic, slightly heavier piqué knit. This classic knitted fabric offers many advantages: It is particularly breathable and keeps its shape, while at the same time being elastic, comfortable and crease-resistant (Fig. 1).

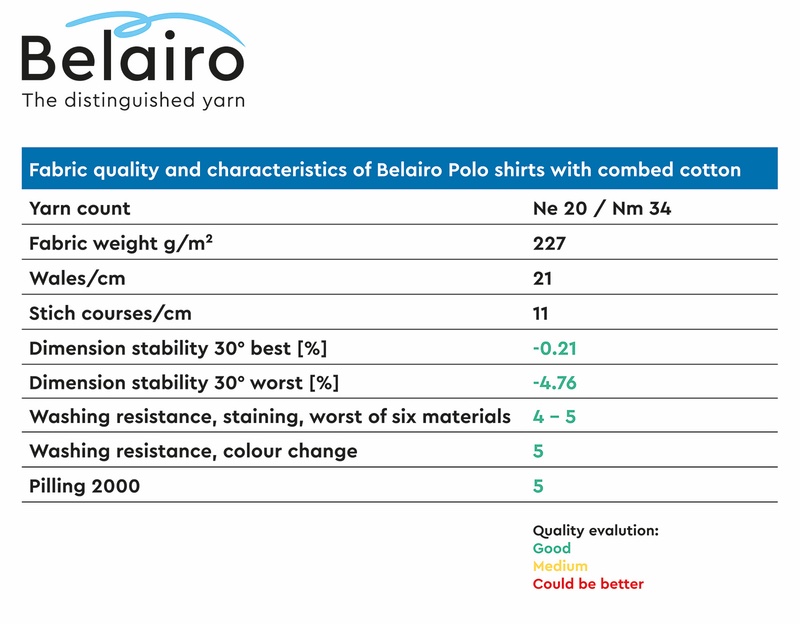

Piqué-knitted fabrics are characterised by a special relief structure with characteristic higher and lower stitches. These knitted fabrics achieve the intended optical depth effect through the use of very smooth yarns, in which the colour is reflected evenly, thus emphasising their characteristic structure. Protruding fibres and especially pilling are highly undesirable with piqué. In order to preserve these characteristics in the knitted fabric over the long term, combed yarns are usually used for piqué, often made from high-quality long-staple cotton. The raw materials for a high-quality polo shirt are generally much more expensive than for a T-shirt (Fig. 2).

When polo shirts are made from ring-spun yarn, the spinning costs are relatively high and the finishing is also complex – all in all, this adds up to challenging production conditions for consumer textiles. With Belairo yarns, spun on the Autoairo air-spinning machine, this balancing act between quality and cost is a thing of the past. Polo shirts made from Belairo yarn have everything that a high-quality business polo shirt must have: an elegant look without pilling, even after 500 washes. The quality advantage does not have to come at a high price, as Belairo yarns can be produced more cost-effectively than ring-spun yarns (Fig.3).

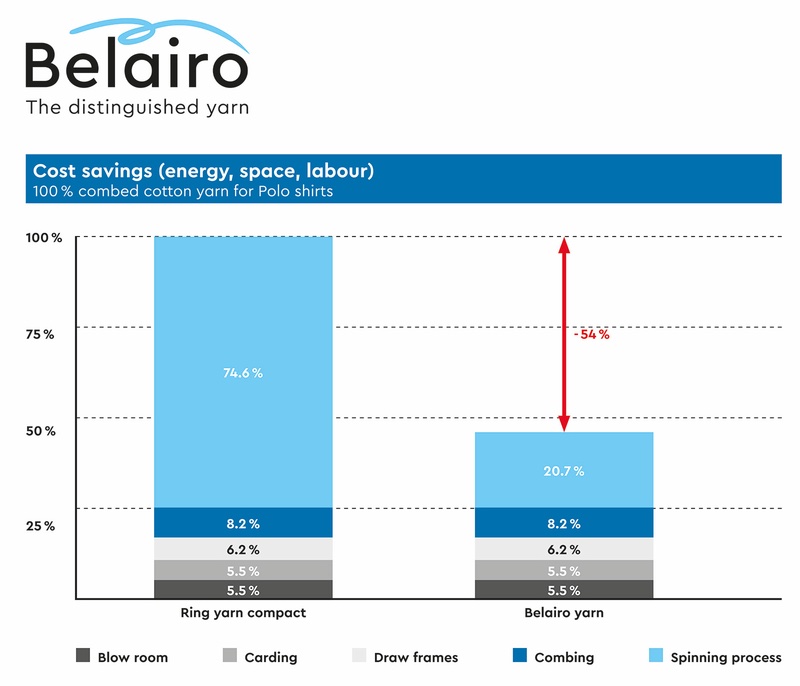

Customised yarn quality saves 50% of costs

Belairo yarns with a ring yarn-like character can reduce the classic spinning costs, energy, labour and space requirements by around half overall. This opens up new opportunities for yarn manufacturers to increase their profitability. The productivity of the Autoairo air-spinning machine is 16 times greater than that of a ring spinning machine. Significantly fewer machines are needed, and the labour and space requirements, as well as the energy consumption per kg of yarn, are considerably lower (Fig 4).

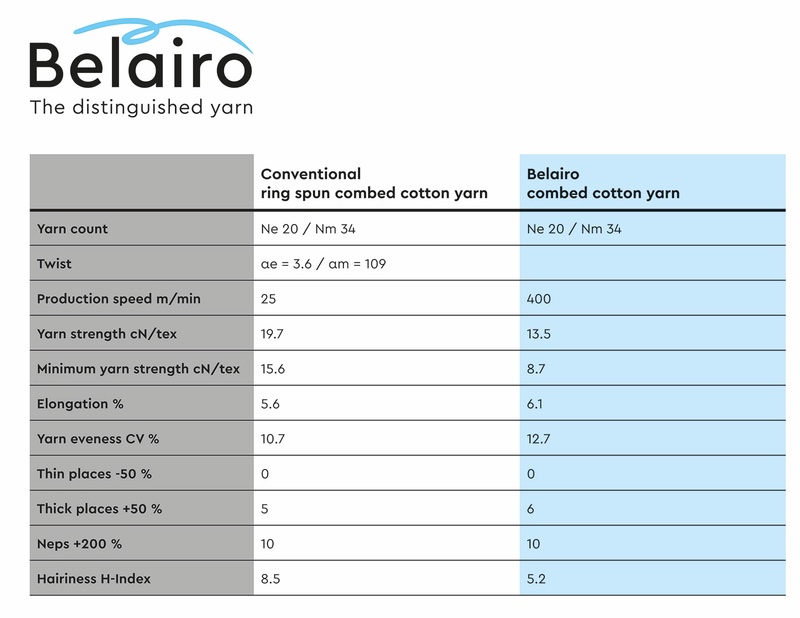

In addition to the economic advantage of Belairo yarns, consumers and processors also benefit from their outstanding quality. The properties of Belairo yarns fulfil the requirements for piqué even better than ring-spun yarns do (Fig. 5).

The yarn-strength requirements of knitting mills are relatively low. The inherently high stability of combed ring yarns is not needed in the knitting process, but high yarn elongation is. Belairo yarns have precisely these properties: sufficient strength, high elongation and extremely low hairiness.

Yarn look and yarn structure of Belairo

The yarn structure of air-spun Belairo yarns consists of a core with parallel core fibres on the inside and wrapping fibres on the outside of the yarn, which wrap around the core and lead to their characteristically low hairiness.

Yarn evenness is determined by a number of parameters. For both ring-spun and air-spun yarns, the classic thin places, thick places and neps are of importance, as these can be visible in the end product. Yarn uniformity is very high with combed ring-spun yarns. This is partly due to the additional process of producing roving bobbins on the roving frame, which involves further mixing of the fibres. The uniformity of Belairo yarns is characterised by a comparable or lower number of classic thin places, thick places and neps. One reason for this is that Belairo yarns experience significantly fewer deflections and friction points during spinning than ring yarns, as they are wound directly onto cross-wound packages and do not require an additional rewinding process.

Thanks to the outstanding yarn quality of Belairo yarns, the knitting machines can produce at their usual high production speeds. The low hairiness of the yarns and the good fibre bonding also extend the cleaning intervals of the knitting machines, as Belairo yarns show significantly less dust and fluff formation than ring yarns.

One manufacturer of high-quality polo shirts has replaced combed ring-spun yarns with combed Belairo yarns. The yarn structure of the air-spun yarn with parallel core fibres and twisted wrap fibres, along with their extremely low hairiness, meet all the requirements that are important for piqué. The result: Piqué knits with brilliant colour reproduction, high dimensional stability, perfect wash fastness and, above all, excellent pilling resistance combined with a good fit.

Finishing polo shirts with Belairo yarn is also less time-consuming than using ring-spun yarns. When ring yarns or rotor yarns are used, the textiles must be treated enzymatically after bleaching in order to remove the loose fibres adhering to the surface. Enzyme-based biopolishing with cellulases removes these fibre fragments, optimally prepares the surface for subsequent dyeing and printing, gives the textile a smoother and softer feel, and reduces the tendency to pill. Biopolishing is effective but expensive, and then also not permanent. The effect lasts for about 30 washes, after which there is a greater likelihood that the surface feel will become harder and the tendency to pill will increase.

With Belairo yarns with their special fibre bonding, biopolishing is not necessary. The knitted fabric can be dyed directly after bleaching. The elimination of cost-intensive biopolishing has a positive impact on the environment, as fewer chemicals are used. The dyeing of Belairo yarns is intensive, the colour pigments penetrate deep into the fibres without chemical pre-treatment and do not fade during the washing process by the end user. Polo shirts with Belairo yarns can be worn for longer by quality-conscious consumers, because they retain their brilliant colours for longer and have a smooth surface without protruding fibres and pilling.