#Spinning

Oerlikon Barmag WINGS FDY Technology for a sustainable polyester yarn production at Garden Silk Mills in India

"We are particularly pleased to have equipped Garden Silk Mills, another successful customer, with our WINGS FDY technology," explained Oerlikon Polymer Processing Solutions CEO Georg Stausberg. "We are confident that the new, state-of-the-art spinning mill will be able to produce polyester yarns for the highest demands in an economically attractive way, so that they can be offered to the Indian market as well as the global market. We congratulate Garden Silk Mills on the successful commissioning and wish them all the best for the future," continued Stausberg.

The FDY yarn expansion project at Garden Silk Mills Private Limited (GSMPL) marks the beginning of a period of rapid progress in the textile sector by The Chatterjee Group (TCG) under the leadership of its visionary Chairman, Dr. Purnendu Chatterjee. With its state-of-the-art manufacturing plant at Jolwa, producing high quality polyester chips, POY, FDY and other specialty yarns, and the iconic Garden Vareli brand having a contemporary collection of sarees and dress materials, the Chatterjee Group, that has investments of USD 8 billion globally, is truly creating the Garden of Tomorrow. “We at MCPI and GSMPL are committed to realize the strong textile vision of Dr. Purnendu Chatterjee, Chairman, TCG”, said D.P.Patra, Whole Time Director and CEO, MCPI.

What is polyester yarn production with Oerlikon Barmag WINGS FDY all about?

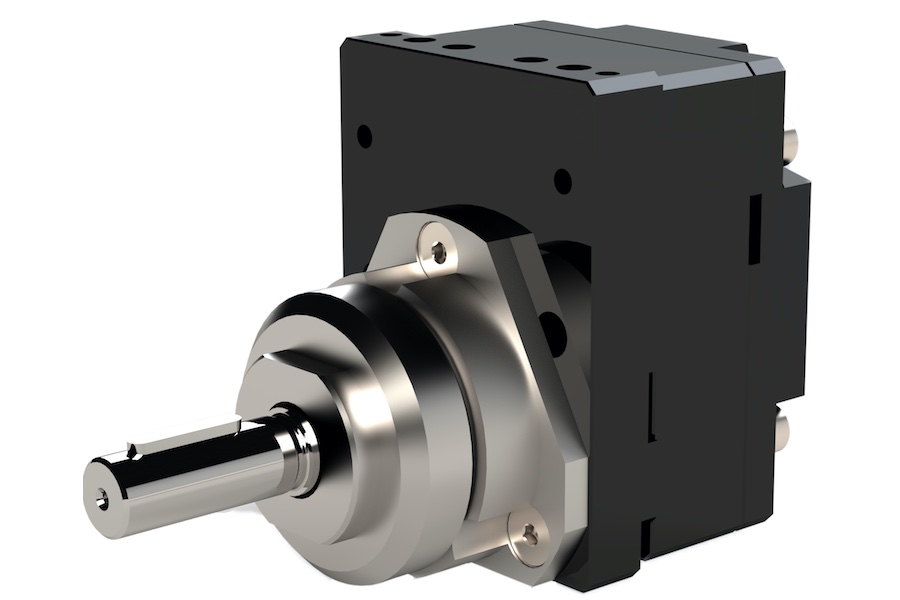

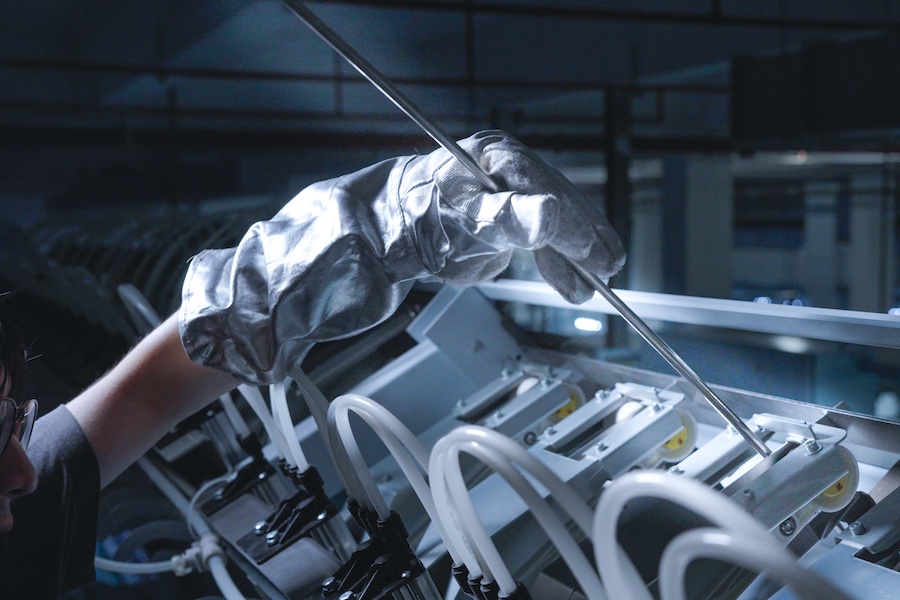

The principle of producing a yarn is always the same: spinning pumps press the plastic melt under extremely high pressure through micro-fine nozzles, the resulting filaments are bundled into threads, stretched over godets, and wound up by a winding head. In order to master this principle reliably, high-precision and extremely stable technology is required. These machines are in use day and night, year in, year out. The slightest error during the spinning process cannot be corrected later.

Precise processes for textile and technical yarns

Oerlikon Barmag systems master almost all processes for the production of textile and technical yarns and spin the common polymers polyester, polyamide 6 and 6.6 or polypropylene. Garden Silk Mills focuses on so-called fully drawn yarns (FDY). They are processed into textile surfaces without further finishing. Fully drawn yarns are used wherever textiles need to fall smoothly or glide.

Sustainable solutions for FDY production

Oerlikon Barmag is the technology leader in this field. The WINGS concept breaks through the limits of conventional FDY spinning systems. WINGS stands for optimized production processes, low waste rates and energy consumption reduced by around 30 percent. High yarn quality is a must. This pioneering technology can be used in the FDY process for polyester and polyamide.

Oerlikon Barmag's WINGS technology now supports Garden Silk Mills in the production of FDY premium yarns – high-performance spinning components such as spinning pumps, spinning beams and spinn packs through to crossflow quenching and the 216 WINGS winders were installed in the direct spinning process downstream of an existing polycondensation system at Garden Silk Mills. This is because the quality of the yarn is determined in the spinning mill.

Competition on the yarn markets is currently also extraordinarily strong for Garden Silk Mills. The result: constantly increasing cost pressure. The solution: optimized production processes, economical systems, sustainable technologies. Oerlikon Barmag WINGS FDY technology provides all of this. Efficiency is the key feature of WINGS: The winder can be operated entirely from the floor. All operating elements are at eye level. As a consequence, this reduces the time required for feeding by 25-40%; time in which FDY yarn of the highest quality can be produced – and, above all, no waste.