#Spinning

Successful in Pakistan

We are thrilled to announce that our sales and service operations in Pakistan are successfully supported in the future, thanks to the unwavering support of our esteemed partners - Service Traders and Tekstil Corporation. We take pride in highlighting the exceptional service capabilities offered by Service Traders, which includes comprehensive repair services for all generations of clearers, top-notch spare parts provision as well as field service assistance coupled with technical consulting expertise.

The Loepfe setup continues with the sales agency of Tekstil Corporation and the partnership with Service Trader for after-sales services. Our heartfelt gratitude goes out to Mr. Kanjee (Service Traders) and Mr. Sheik Mansour (Tekstil Corporation), whose invaluable contributions played an instrumental role in making this setup a success.

Exceptional client support and service

Loepfe understands the competitive business landscape in Pakistan and providing exceptional service has become a key differentiator for our clients and users. Service Traders managed to build and maintain strong relations with Loepfe users by offering effective and efficient services at any time. There is guaranteed availability of spare parts in the country and reliable technical support for all clearer generations. The skilled and experienced team guarantees service support from the moment of installation throughout the entire lifespan of the products.

We are currently in the process of handing over the responsibilities from Mr. Kanjee to the new CEO of Service Traders Mr. Amir Memon, as we prepare for Mr. Kanjee's much-deserved retirement. We want to express our heartfelt gratitude towards him for the unwavering dedication and hard work he has put into serving our customers and partners over the years.

As he embarks on a new chapter in life, we wish him nothing but success and happiness.

Introducing Mr. Amir Memon

As an experienced electronics engineer with over two decades of sales and service experience in the dynamic textile sector, Mr. Memon has had the opportunity to collaborate with leading multi-national enterprises and build strong relationships with key customers, partners, cohesive teams, and stakeholders. His technical skills and profound expertise in the domain of electronics, automation, and controls have allowed him to provide innovative solutions to complex problems faced by the textile industry. Mr. Memon’s excellent problem-solving and analytical skills have enabled him to identify and address issues promptly, ensuring smooth operations and high-quality output. As a seasoned professional in the textile industry, Loepfe is confident that with his expertise, skills, and passion Mr. Memon will make a significant contribution to the organization.

New CEO of Service Traders, Mr. Amir Memon: “I am honored to assume the position of CEO at this remarkable company. As I step into this role, I am eager to share my vision and commitment to driving our organization forward. First and foremost, my utmost gratitude goes to my predecessor, whose leadership and dedication set a strong foundation for our company's success.

With a steadfast focus on collaboration and customer-centricity, my aim is to propel our company to new heights. I look forward to working alongside Loepfe to achieve shared success.”

Former CEO of Service Traders, Mr. Kanjee: “After many years of unwavering commitment and dedicated service, I am announcing my retirement as CEO of Service Traders. It has been a privilege and honor to lead such a talented and passionate group of individuals and to serve, discuss and achieve the best with our valued customers.?I am thankful to Loepfe Brothers Ltd, the invaluable partner. Unwavering support and collaboration from Loepfe have played a pivotal role in my achievements. I am truly grateful for the strong bond we have formed.

Mastering the challenging environment

Operating in a challenging environment, Pakistani spinning mills face numerous obstacles. The harsh climatic conditions of high temperatures and humidity create difficulties in producing consistent yarn quality. Moreover, the raw materials processed by the mills are often contaminated which adds to their woes.

Despite such challenges, Pakistani spinning mills have managed to stay competitive on an international level through their flexibility. They produce a wide range of articles from coarse to fine yarns for weaving, knitting and denim production - all while keeping up with global market demands.

However, this adaptability comes at a cost as it requires extensive time and labor investment; yet they continue striving towards excellence despite adversities faced along the way.

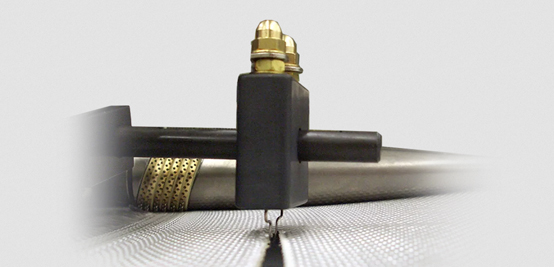

To meet the diverse requirements of spinning mills, a clever quality control system is essential. Fortunately, Pakistani spinning mills have found their solution in YarnMaster® PRISMA - an exceptional system that produces high-quality yarns across various counts and challenging environments while maintaining winding machine efficiency.

PRISMA handles contaminants with ease, and securely detects missing and offcenter cores, slub readers and much more, while providing a detailed overview of the yarn conditions. PRISMA's recent Autostart function has been a game-changer for multiple article changes by reducing setting time by up to one hour for new articles! Likewise, the persons in charge can be sure that with PRISMA’s built-in intelligence, the winding process is set up for optimum performance. It provides a balance between yarn quality and machine efficiency. It also assists new operators and prevents the production of insufficient yarn quality due to incorrect settings.

By adopting PRISMA, Pakistani spinners have witnessed a decrease in yarn waste, splice cycles and energy consumption while enhancing the quality of their produced yarns.